Are you looking for a direct and efficient way to heat liquids? Immersion heaters might be the perfect solution. But how do they work, and are they suitable for your specific needs?

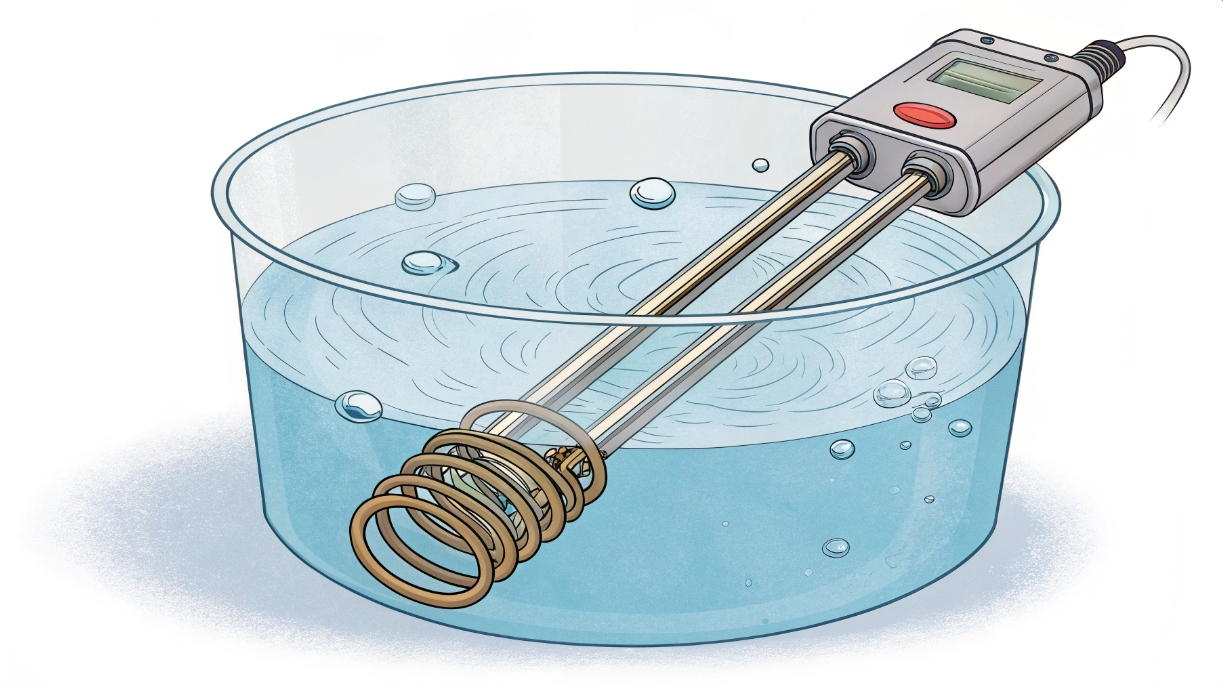

An immersion heater is a device that heats liquids directly by submerging a heating element into the liquid. They are very efficient because almost all the energy is transferred to the liquid.

So, let’s explore the world of immersion heaters. I want to share my knowledge, gained from years of experience at ELEKHEAT, to help you understand these useful devices better.

What Is an Immersion Heater? How Does It Work?

Do you know how these heaters turn electricity into heat right inside a liquid? It’s simpler than you might think.

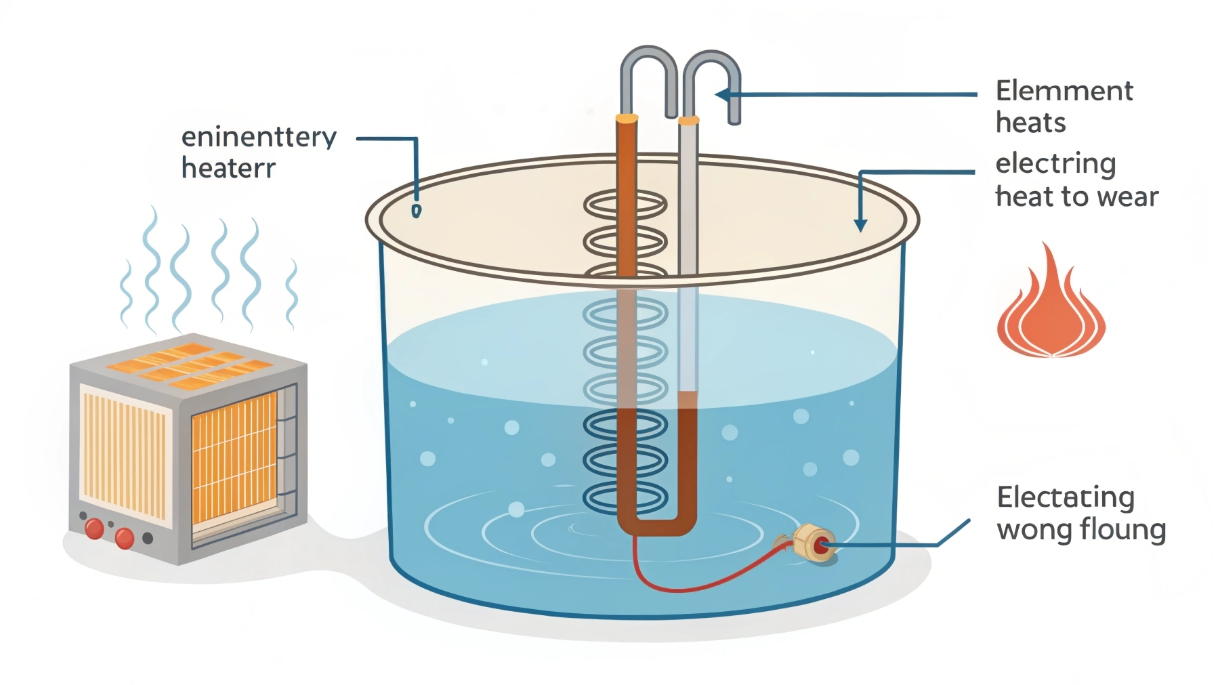

Immersion heaters work by using a heating element that is immersed directly into the liquid that needs to be heated. When electricity flows through the element, it heats up, and this heat is transferred directly to the surrounding liquid.

What are the key components of an immersion heater?

Immersion heaters have several key parts. Each part plays a very important role in how the heater works.

| Component | Function |

|---|---|

| Heating Element | Converts electrical energy into heat. Usually made of materials like stainless steel. |

| Sheath | Protects the heating element from corrosion and direct contact with the liquid. |

| Connection Housing | Provides a safe enclosure for electrical connections and protects them from the environment. |

| Thermostat | Regulates the temperature of the liquid by controlling the power supply. |

At ELEKHEAT, we carefully select each component to make sure our heaters are durable and work well. The heating element is the core of the heater. The sheath protects it, and the thermostat keeps the temperature stable. This design helps our heaters last longer and work better. I remember one time when we used a new type of stainless steel for a client’s heater. It significantly improved the heater’s resistance to corrosion, and the client was very happy with the improved lifespan.

What Are the Pros and Cons of Immersion Heaters?

Are you wondering if an immersion heater is the right choice? Like any heating solution, they have advantages and disadvantages.

Immersion heaters are efficient because they directly heat the liquid. However, they can be a safety risk if not used properly. They can also cause corrosion if the wrong material is used for the element. The cost can be high if the heater needs to be replaced often.

What are the main factors to consider?

When deciding whether to use an immersion heater, there are several things to think about.

| Factor | Pros | Cons |

|---|---|---|

| Energy Efficiency | Very efficient because almost all heat is transferred directly to the liquid. | Can be less efficient if the tank is poorly insulated, leading to heat loss. |

| Cost | Relatively low initial cost compared to other heating systems. | Can have higher long-term costs if the heater requires frequent repairs or replacements. |

| Safety | Some models come with safety features like automatic shut-off to prevent overheating. | Can be a safety hazard if not used correctly, posing risks of electric shock or burns. |

| Maintenance | Simple design makes maintenance relatively easy. | Requires regular inspection and cleaning to prevent scale buildup and corrosion. |

| Applications | Versatile and can be used in a variety of applications, from small tanks to large industrial processes. | Not suitable for all types of liquids, especially those that are highly viscous or contain solids. |

At ELEKHEAT, we always advise our customers to consider these factors. For example, if you’re heating a corrosive liquid, you need a heater with a special coating. We had a client who used a standard heater in a chemical tank. The heater failed quickly. We replaced it with a titanium heater. It lasted much longer. Choosing the right materials and considering safety features is very important.

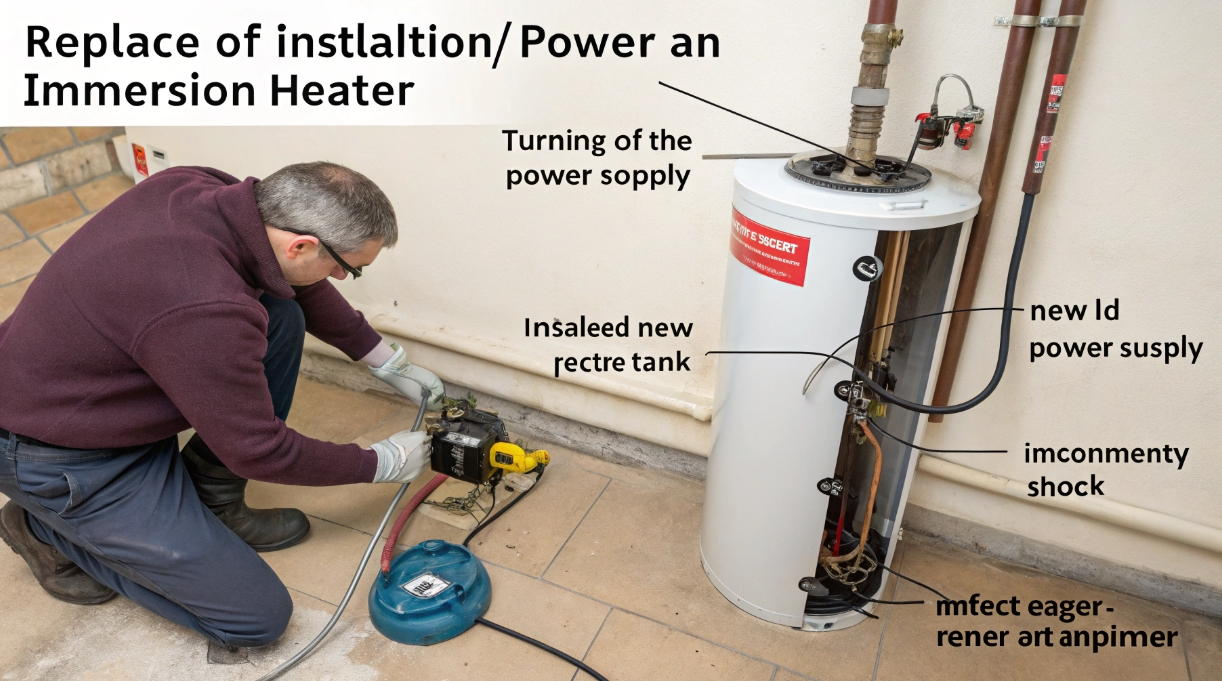

How to Replace or Install an Immersion Heater?

Is your immersion heater not working well? Or do you want to install a new one? It’s important to know the right steps to avoid problems.

Replacing or installing an immersion heater involves a few key steps: first, you need to turn off the power. Then, drain the tank, remove the old heater, install the new one, and reconnect the power. Always follow safety guidelines to avoid electric shock.

What are the essential safety precautions?

When installing or replacing an immersion heater, safety is the most important thing.

| Safety Precaution | Description |

|---|---|

| Disconnect Power | Always turn off the power supply to the heater at the circuit breaker before starting any work. |

| Verify No Power | Use a multimeter to confirm that the power is off before touching any electrical connections. |

| Wear Safety Gear | Wear safety glasses and gloves to protect yourself from potential hazards. |

| Follow Instructions | Carefully read and follow the manufacturer’s instructions for installation and operation. |

| Inspect the Heater | Check the heater for any signs of damage before installation. |

| Use Correct Tools | Use the right tools for the job to avoid damaging the heater or causing injury. |

| Test After Installation | After installation, test the heater to ensure it is working properly and safely. |

I remember one time when a technician didn’t turn off the power before working on a heater. He got a shock. Luckily, he was okay, but it was a very important reminder. At ELEKHEAT, we always stress the importance of safety. We provide detailed guides and training to our staff. This helps prevent accidents and ensures that every installation is done correctly.

Conclusion

Immersion heaters are efficient and useful for heating liquids directly. Consider your specific needs, safety, and energy use when choosing one.