After the customer purchases and tests the size specifications and voltage power and other conventional parameters of the electric heating tube, the electric heating tube will enter the normal use stage. But how to ensure the safe use of the heating tube? Next, we will have Elekheat professionals explain it to you in detail.

01

Precautions before installing the electric heating tube

1.1 Key points for the use of single-head heating tubes

1.1.1 How to use conventional single-head electric heating tubes

Under normal circumstances, single-head tubes can usually be used directly without special fixation. It can be directly placed in the heating channel for heating, or fixed and heated by a bracket.

1.1.2 Baffle-type single-head electric heating tube

It is necessary to drill a hole on the installation surface, which can be installed horizontally or vertically, and the baffle protects the lead. Baffle-type single-head electric heating tubes usually need to drill a hole on the installation surface to allow the electric heating tube to pass through, and the baffle plays a role of fixing and supporting. It can be installed horizontally or vertically, and when installed horizontally, the baffle mainly plays the role of protecting the lead.

1.1.3 Threaded single-end electric heating tube

Adding welding thread, convenient installation and simple replacement. The threaded single-end electric heating tube has an additional installation thread welded on the original basis to simplify the installation process. The common installation method is to drill a hole with a thread at the predetermined position, and then the electric heating tube can be easily fixed by the thread. The advantages of this design include:

- Convenient installation

- Simple replacement

- Reliable sealing

- Good stability

(The thread size is usually 6 points or one inch, etc.)

1.2 Installation method of U-shaped heating tube

1.2.1 Fastener and bracket installation

Drilling and threading fasteners are easy to replace and stable. Fastener installation is a common installation method, which requires drilling a suitable hole diameter at the predetermined position. Fasteners mainly include threaded fasteners, and in order to enhance the stability of the installation, they are usually used with gaskets. The advantages of this installation method include:

- Simple operation

- Strong stability

- Easy replacement

- Wide range of applications

For long tube or horizontal installation: Ensure stability. When the electric heating pipe needs to be installed horizontally or the heating pipe is long, using only fasteners may not ensure sufficient stability, because the fasteners may not be able to bear the weight of the pipe and are easily damaged. Therefore, brackets are usually used to ensure the stability and durability of the installation.

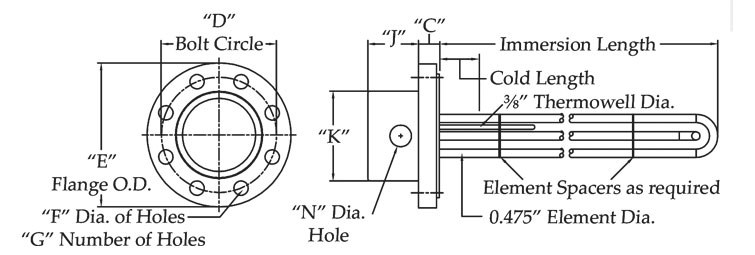

1.2.2 Installation of flange heating pipes

Bolt holes are reserved on the flange, and the heating pipe is fixed with bolts to the female flange. Flange heating pipes can be mainly divided into two categories according to their installation methods: flat flange and threaded flange.

Flat flange installation:

When designing a flat flange electric heating pipe, several bolt holes will be reserved on the flange for fixing with bolts. During the installation process:

- Weld the matching female flange to the installation position

- Fix the heating pipe flange to the female flange

- Use sealing gaskets to ensure proper sealing

Threaded flange installation:

(Common thread specifications: 1 inch or 1.5 inches)

Installation process:

- Pre-drill a threaded hole at the installation location

- Rotate the threaded flange directly into the hole

- Secure to fix the heating tube