Cable heaters seem simple. But they solve complex temperature problems everywhere. I’ve seen industries transform with the right cable heater solution.

Yes. Cable heaters provide precise, durable heat for tough industrial freeze protection and process heating. They resist corrosion. They offer flexible installation. You get reliable heat exactly where you need it, energy efficiently.

Next, we look closely at different types and where they excel. Each type solves a specific problem well.

Mineral Insulated Cable Heaters: Do They Really Handle Extreme Heat?

Factories need serious heat. Equipment often runs hot. Mineral insulated cables deliver intense temperature reliably.

Yes. Mineral insulated cable heaters work in extremely high-temperature industrial settings. The magnesium oxide insulation withstands intense heat, perfect for ovens, reactors, and pipes needing temperatures up to 1400°F (760°C). It lasts.

Understanding Mineral Insulated Heater Benefits and Limits

This heater type brings distinct advantages for harsh conditions. People choose it for critical applications.

We all need heaters that survive intense heat. Mineral insulated cables excel here. The mineral insulation core resists melting. It also conducts heat very efficiently from the element to the surface. You get consistent high heat output. The durable metal sheath protects the core.

But, these cables bend much less easily. Installing complex paths is harder. They cost more upfront than other cable types. However, the extreme temperature capability and long lifespan often justify this cost. Below explains key pros and cons:

| Feature | Advantage | Consideration |

|---|---|---|

| Max Temperature | Up to 1400°F (760°C) | Lower flexibility |

| Durability | Long life + High Corrosion Resistance | Higher initial material cost |

| Heat Transfer | Fast + Efficient | Rigid Installation Paths Needed |

| Power Density | Very High | Requires careful sheath selection |

Therefore, they are ideal for furnace parts, heavy machinery, and chemical processing. They handle the heat others can’t. We customize sheath alloys for difficult chemical environments too. I remember a client needing them for harsh chemical plant piping.

Installation Guide: How Do You Properly Fit Self-Regulating Heat Cables for Freeze Protection?

Frozen pipes are costly. Self-regulating heat cables prevent this. Getting the installation right matters most.

Installation success depends on surface prep and correct spacing. Clean the pipe well. Secure the cable tightly in straight runs or specific patterns. Always plug the cable into a dedicated GFCI circuit for safety. Test it pre-winter.

Key Installation Steps for Reliability

A correct fit prevents failures. Skipping steps causes cold spots and power problems.

First, you must clean the pipe surface completely. Dirt or grease stops the cable from transferring heat well. Dry the pipe fully. Position the cable how the plan shows – straight, spiral loops, or multiple lines. Spacing is critical if using multiple runs. Fix it tightly with fiberglass or aluminum tape. Don’t use plastic or duct tape. Use supplied clips too.

Next, secure the connection box away from moisture. Never submerge it. Use the correct electrical plug. Only use GFCI protected outlets. They stop electric shocks if water touches the cable. Insulation over the pipe and cable boosts performance significantly. Finally, check if the cable warms up correctly before cold weather arrives. We recommend a practice run. Here’s a quick safety checklist:

- Clean Pipe: Grease-free, dry surface.

- Secure Correctly: Use high-temp tape/clips.

- Connection Box: Mounted dry, accessible.

- Power Source: Dedicated GFCI outlet only.

- Insulation: Full coverage over pipe and cable.

- Pre-Season Test: Verify heating function works.

This process prevents ice blockages and power issues through winter. A careful install saves money and headaches. My field techs see failed installations from skipped steps often.

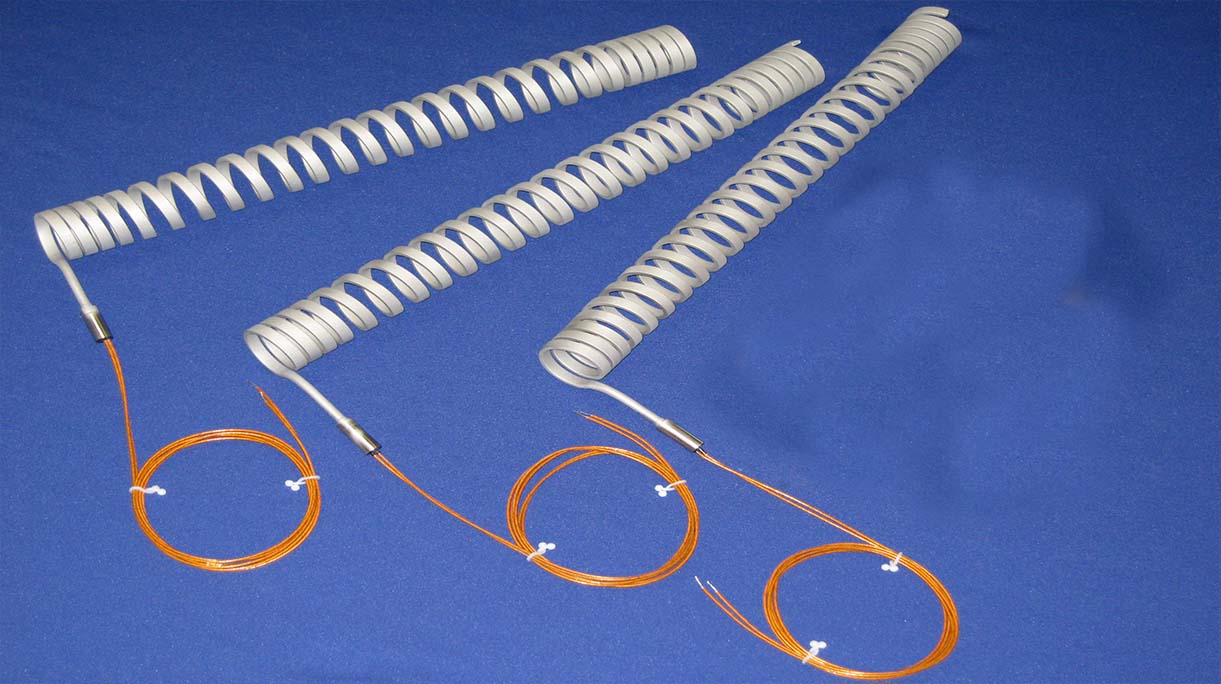

Coil vs. Cable Heaters: Which Heating Element Fits Your Specific Application?

Choices matter. Coil and cable heaters look different. They also work best in different places.

Select coil heaters for focused heat in small areas like injection molds. Choose flexible cable heaters for protecting pipes or adding heat to long surfaces. The shape and flexibility decide the best fit for your job.

Detailed Differences and When To Use Each

Understanding their distinct roles helps pick the best heater for your purpose.

Coil heaters wrap tight circles. This concentrates output on a small spot. They work well fitting into holes for mold heating or lab equipment. People know them as cartridge heaters too. They push intense heat into metal fast. But, they cover a very limited area. They don’t flex.

Cable heaters are long and bendable. You can run them along a process pipe for meters. Or loop them across a large tank base. Self-regulating types adjust output along their length automatically. They prevent freezing over large distances. Silicone rubber jacketed cables also handle moisture or mild chemicals well. Think pipe tracing or roof/gutter applications:

| Application Need | Better Choice | Reason |

|---|---|---|

| Heat Small Hole/Niche | Coil Heater | Concentrated power, compact design |

| Trace 30ft Pipe | Cable Heater | Flexible, uniform heat over long distance |

| Mold Temperature | Coil Heater | High power density in confined space |

| Prevent Pipe Freeze | Self-Regulating Cable | Adapts output, installs on curves easily |

| Chemical Washdown | Teflon Cable | Corrosion resistant sheath needed |

We make both. Our team asks about space limits and heat goals to advise best. It’s not one is better. It’s which one fits where.

Agricultural Uses: Can Cable Heaters Effectively Prevent Livestock Waterer Freeze-Ups?

Water freezes. Animals need drinking water daily. Frozen troughs cause big problems for farms.

Yes. Specially designed heating cables reliably stop livestock water troughs from freezing. Energy-efficient self-regulating types work best. They wrap tanks or run under water lines. They keep water liquid even at very low temperatures.

Making Livestock Water Heating Work Efficiently

Farm needs are tough. The heaters must survive cold, wet, and rough animal environments.

First, only use heaters made for this purpose. Standard cables might fail. Look for immersion-rated waterproof cables. Or robust frost protection cables meant for wet contact. Installation is key. Secure the cable safely away from the animals’ teeth! Mount it low on the tank wall or under the base as design specifies. Silicone rubber jacketing handles sun and animal knocks well.

Using a thermostat saves significant energy. It turns the cable on only below 40°F (4°C). Self-regulating types naturally draw less power as the air warms. This keeps operating costs down. Combine the heater with a tank cover or foam insulation blocks. This reduces heat loss dramatically. Reliable water year-round protects animal health and saves labor costs. I’ve watched farmers break ice daily. It’s a heavy, cold job. Heaters prevent that.

Top 10 Industrial Cable Heater Brands Compared: Who Leads in Performance?

Many brands promise quality. Performance varies. Some stand out with reliable solutions.

Top brands include Watlow, Tempco, Durex, Chromalox, OMG, Nelson, Raychem, BriskHeat, Backer, and Vulcanic. ELEKHEAT offers strong alternatives. We provide custom solutions with faster delivery, good for unique industrial applications.

How Major Cable Heater Brands Stack Up for Specific Needs

Choosing a brand involves matching their strengths to your specific requirements. Every project has different priorities.

You need to know what matters most for your application. Is it very high temperature? Extreme chemical resistance? Or fast delivery? Top-tier brands excel in one or two areas:

- Tempco Solutions: Known very well. Great consistency. Good for standard needs.

- Watlow Electric: Strong engineering focus. Excellent for custom complex jobs.

- Durex Industries: Strong presence in plastics/heavy industry heating. Durable builds.

- Chromalox: Broad range of heating solutions including cables. Established name.

- OMG (Spirafix): Great reputation for pipe freeze protection systems. Robust construction.

- Nelson (Heat Trace Specialists): Strong in pipe tracing globally. Broad portfolio.

- Raychem/TE Connectivity: Pioneered self-regulating tech. Premium for critical tracing.

- BriskHeat: Known for portable solutions and silicone heat belts. Flexible options.

- Backer Marathon: Reliable standard cable. Good for OEM in appliances.

- Vulcanic Group: European engineered solutions. Performance in process heating.

For custom builds or faster project timelines, we offer competitive alternatives. We design unique cable heaters tailored exactly to machine or process specifications. We ship reliably from our large factory. Often quicker than big-brand lead times. Our quality control matches industry standards. Remember to compare warranty periods too. We offer competitive terms.

Conclusion

Cable heaters are versatile temperature control solutions. They solve freeze issues and boost efficiency across industries. We supply custom heaters reliably.