Are you struggling to maintain consistent temperatures in your industrial processes? Do you need a reliable heating solution that fits directly into your tanks or vessels?

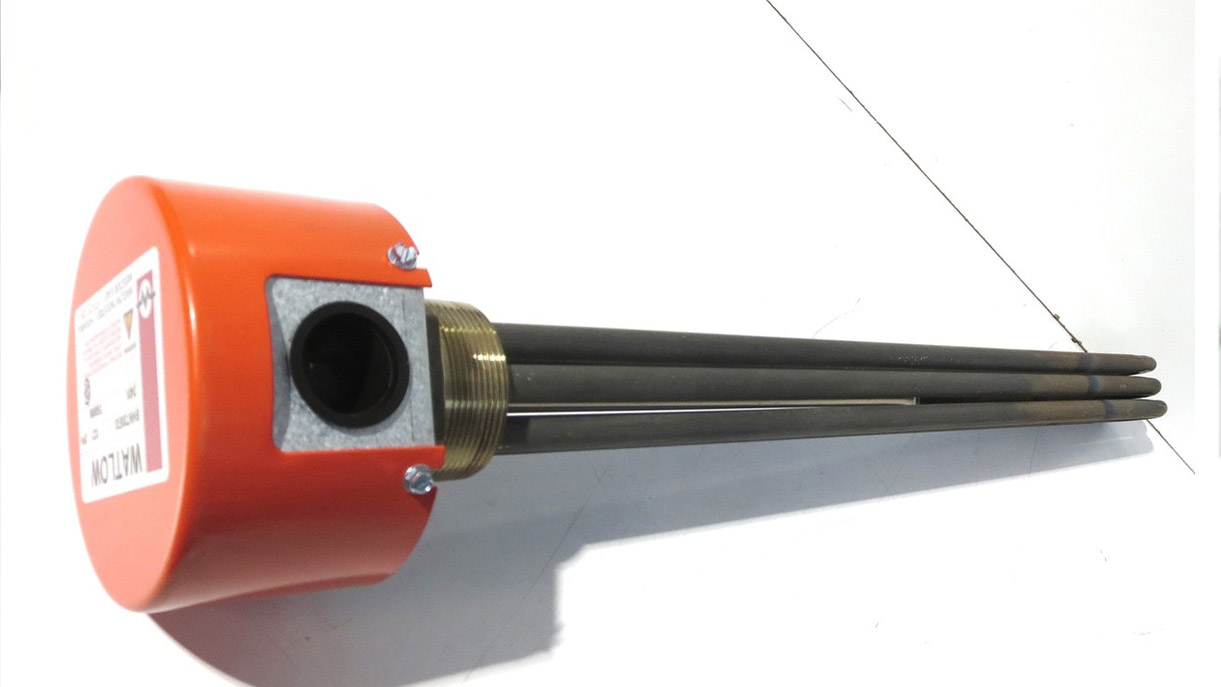

Screw plug immersion heaters are a great option for heating liquids in tanks and pressure vessels. They directly heat the medium, offering high efficiency and precise temperature control. They are easy to install and maintain, making them suitable for various industrial applications.

Choosing the right heater is crucial for efficient and safe operation. Keep reading to learn how to select and maintain screw plug immersion heaters for your specific needs.

How to Choose the Right Screw Plug Immersion Heater for Your Industrial Needs?

Are you feeling lost trying to figure out which screw plug heater is best for your application? Do you feel that the specifications are too complex to understand?

Selecting the correct screw plug immersion heater involves considering factors like the liquid type, tank size, desired temperature, and material compatibility. You should also factor in voltage, wattage, and thread size.

When choosing a screw plug immersion heater, there are a few key factors to consider. These factors ensure optimal performance and longevity.

First, you need to consider the liquid type and material compatibility. Different liquids react differently with various materials. For example, corrosive solutions require materials like stainless steel or titanium. These materials can withstand the chemical reaction. You should always check a material compatibility chart before making a decision.

Second, you have to factor in voltage and wattage. Voltage determines the electrical supply needed. Wattage affects the heating speed. Make sure the heater’s voltage matches your power supply. You should also select the appropriate wattage based on the volume of liquid.

Third, consider the thread size and tank compatibility. The thread size must match the opening on your tank or vessel to ensure a secure fit.

Here’s a table to help you further understand this:

| Factor | Considerations | Example |

|---|---|---|

| Liquid Type | Corrosiveness, viscosity, specific heat | Water, oil, chemical solutions |

| Material | Compatibility with liquid, temperature resistance | Stainless steel, copper, Incoloy |

| Voltage & Wattage | Power supply compatibility, heating time requirements | 240V, 480V; 1kW to 50kW |

| Thread Size | Tank opening size | 1", 1.25", 2", 2.5" NPT |

| Temperature Control | Required temperature accuracy | Thermostats, thermocouples |

| Safety Features | Over-temperature protection, grounding | Thermal cutouts, ground wires |

Choosing the right heater may seem complex. However, by considering these factors, you can ensure efficient and safe heating for your industrial processes. At ELEKHEAT, we can guide you through the selection process. We will make sure you get the perfect heater for your specific application.

Top 5 Applications of Screw Plug Immersion Heaters in Industrial Settings?

Are you wondering where screw plug immersion heaters are most useful? Do you want to see how other industries are using them to improve their processes?

Screw plug immersion heaters are used in industries like chemical processing, oil and gas, food and beverage, and water heating. They’re often found in tanks, pressure vessels, and other containers requiring controlled heating.

Screw plug immersion heaters are incredibly versatile. They can be used across various industries. Here are five key applications.

-

Chemical Processing: In chemical plants, these heaters maintain precise temperatures for chemical reactions. This ensures product quality and consistency. For example, a chemical company might use a stainless steel screw plug heater to heat a solution. This will speed up a reaction without contaminating the mixture.

-

Oil and Gas: The oil and gas industry uses these heaters to prevent pipeline freezing. They also reduce the viscosity of heavy crude oil. This makes it easier to transport. A refinery might install a high-wattage heater to maintain the temperature of oil flowing through a pipeline.

-

Food and Beverage: Food processing plants use screw plug heaters for cooking, pasteurization, and sterilization. They help maintain food safety standards. A beverage company might use a heater to pasteurize juice. This kills bacteria and extends shelf life.

-

Water Heating: Many industries require large volumes of hot water for cleaning and sanitation. Screw plug heaters provide an efficient way to heat water in large tanks. A manufacturing plant might use a heater to preheat water for its cleaning processes.

-

Wastewater Treatment: Screw plug heaters can heat wastewater to speed up the evaporation or disinfection process. This helps to reduce the volume of waste and remove contaminants. A wastewater treatment plant might use a heater to increase the temperature of sludge. This will improve the efficiency of the drying process.

Each of these applications highlights the heater’s ability to provide direct and efficient heating. This makes them an important part of many industrial processes. ELEKHEAT offers custom solutions. These solutions ensure you get the right heater for your specific industry needs.

Screw Plug vs. Over-the-Side Immersion Heaters: Which is Best for Your Tank?

Are you torn between choosing a screw plug or an over-the-side immersion heater? Do you want to know which one is best for your specific tank setup?

Screw plug heaters install directly into a threaded opening in the tank wall. Over-the-side heaters hang over the tank’s edge. Screw plugs are good for closed systems needing high efficiency. Over-the-side heaters are better for open tanks or when easy removal is needed.

Deciding between screw plug and over-the-side heaters depends on your specific needs. Each type has its own benefits and drawbacks.

Screw plug heaters are ideal for closed tanks and pressure vessels. They provide a secure and leak-proof fit. They are also more energy-efficient since they directly heat the liquid. However, they require a threaded opening in the tank, which may require modification.

Over-the-side heaters, on the other hand, are easy to install and remove. They simply hang over the edge of the tank, making them suitable for open tanks or temporary heating needs. However, they may not be as energy-efficient. They also have a higher risk of damage since they are exposed.

Here is a comparison table to help you decide:

| Feature | Screw Plug Heaters | Over-the-Side Heaters |

|---|---|---|

| Installation | Requires threaded opening | Hangs over the tank edge |

| Efficiency | Higher, direct heating | Lower, more heat loss |

| Tank Type | Closed tanks, pressure vessels | Open tanks, temporary heating |

| Maintenance | More complex, requires draining the tank | Easier, can be removed without draining the tank |

| Cost | Generally higher initial cost | Generally lower initial cost |

| Applications | Chemical processing, oil heating | Plating tanks, parts washing |

Choosing the right heater can significantly impact your process efficiency and cost. At ELEKHEAT, we offer both types of heaters. We can help you assess your needs and select the best option.

Maintenance Tips for Screw Plug Immersion Heaters: Extending Lifespan & Efficiency?

Are you looking for ways to make your screw plug heaters last longer? Do you want to keep them running efficiently to save money?

To extend the lifespan of screw plug immersion heaters, regularly inspect them for corrosion, scale buildup, and electrical damage. Clean the heating elements periodically, ensure proper wiring connections, and replace any damaged components promptly. Proper maintenance will ensure efficient and safe operation.

Proper maintenance is essential for extending the lifespan and efficiency of your screw plug immersion heaters. Neglecting maintenance can lead to costly repairs and downtime.

First, you should regularly inspect the heaters for corrosion and scale buildup. Corrosion can weaken the metal. Scale buildup reduces heat transfer. Use a brush or chemical cleaner to remove any deposits.

Second, check the electrical connections regularly. Loose connections can cause overheating and electrical hazards. Make sure all wiring is secure and free from damage.

Third, monitor the heater’s performance. If you notice a decrease in heating efficiency, it may be a sign of a problem. Check the resistance of the heating elements. Replace them if necessary.

Finally, keep a maintenance log. This helps you track when maintenance was performed and what issues were addressed. This can help you anticipate future problems and schedule maintenance proactively.

Here’s a quick checklist for maintaining your screw plug immersion heaters:

| Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Monthly | Check for corrosion, scale buildup, and physical damage. |

| Electrical Connections | Quarterly | Ensure all wiring is secure and free from damage. |

| Cleaning | Semi-Annually | Remove scale and deposits from heating elements. |

| Performance Monitoring | Monthly | Monitor heating efficiency and check for any unusual noises or vibrations. |

| Resistance Check | Annually | Measure the resistance of the heating elements and replace if necessary. |

By following these maintenance tips, you can ensure your screw plug immersion heaters operate efficiently and reliably for years to come. ELEKHEAT provides maintenance services. We can help you keep your heaters in top condition.

Understanding Voltage, Materials, and Thread Sizes in Industrial Screw Plug Heaters?

Are you confused about the different voltage options for screw plug heaters? Do you know why material selection is so important?

Industrial screw plug heaters come in various voltages (e.g., 240V, 480V), materials (e.g., stainless steel, copper), and thread sizes (e.g., 1", 2"). Voltage must match the power supply. Material must be compatible with the liquid. Thread size must fit the tank opening.

Understanding the details of voltage, materials, and thread sizes is crucial for selecting the right screw plug heater for your industrial application.

Voltage: Industrial screw plug heaters typically operate at higher voltages. Common options include 240V, 480V, and even 600V. The voltage you choose must match your facility’s electrical supply. Using the wrong voltage can damage the heater or cause a fire.

Materials: The material of the heater is important for its durability and compatibility with the liquid being heated. Stainless steel is a popular choice for its corrosion resistance. Copper is a good conductor of heat. Incoloy is used for high-temperature applications.

Thread Sizes: Screw plug heaters come in various thread sizes. Common sizes include 1", 1.25", 2", and 2.5" NPT (National Pipe Thread). The thread size must match the opening on your tank or vessel. Using the wrong thread size can result in leaks or an insecure fit.

Here is a table summarizing the key considerations for each factor:

| Factor | Considerations | Examples |

|---|---|---|

| Voltage | Match the heater voltage to your facility’s power supply. | 240V, 480V, 600V |

| Materials | Choose a material that is compatible with the liquid being heated and can withstand the operating temperature and pressure. | Stainless steel, copper, Incoloy |

| Thread Size | Ensure the thread size matches the opening on your tank or vessel to ensure a secure and leak-proof fit. | 1", 1.25", 2", 2.5" NPT |

Choosing the correct voltage, material, and thread size can seem complicated. However, understanding these factors will help you select a heater that meets your specific needs. ELEKHEAT offers a wide range of screw plug heaters with various options. We can help you find the perfect heater for your application.

Conclusion

Screw plug immersion heaters are efficient and versatile for various industrial heating needs. Selecting the right heater and maintaining it properly will ensure optimal performance and extend its lifespan.