The Ultimate Circulation Heater Guide

A complete technical resource for engineers and managers who specify, operate, and maintain critical **industrial circulation heaters**. This guide provides the data-driven insights you need to ensure efficiency, reliability, and safety in your application.

Article Directory

What is an Inline Circulation Heater?

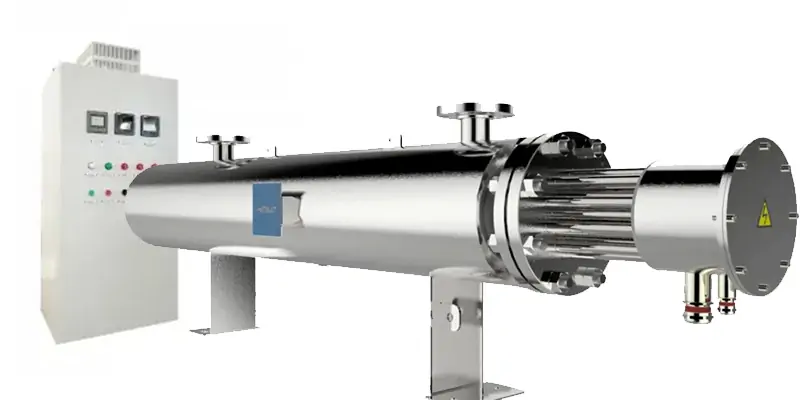

At its core, an **inline circulation heater** is a self-contained, packaged heating system designed for the efficient heating of flowing liquids or gases. Unlike a simple immersion heater component, a circulation heater is a complete, pre-engineered system. It integrates an immersion heater into a robust, insulated pressure vessel, providing a ready-made solution that saves engineering time, reduces installation labor, and lowers total cost of ownership.

Immersion Heater vs Circulation Heater: The Key Distinction

An Immersion Heater is a component designed to heat static fluids in a tank. A Circulation Heater is an integrated system engineered to heat a dynamic, flowing medium within a pipeline. It solves the complex problem of applying precise heat to a process stream, a task an immersion heater alone cannot address.

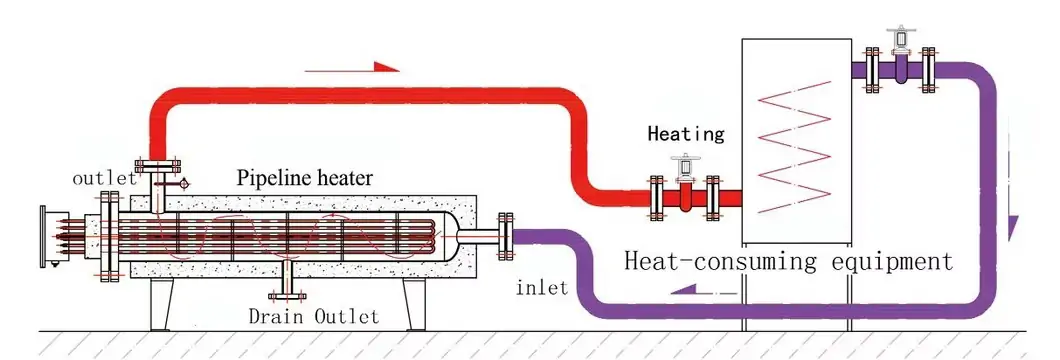

How Industrial Circulation Heaters Work

The operating mechanism is a model of efficiency. A process fluid is pumped into the vessel inlet, flows directly over the heating elements, and exits at a higher, precisely controlled temperature. This direct heating method approaches 100% efficiency by minimizing thermal loss.

The process is governed by conduction and convection, but the key to its effectiveness is engineered turbulent flow. Internal baffles disrupt the fluid's path, forcing chaotic mixing. This turbulence dramatically increases the heat transfer rate, ensuring the fluid heats evenly and preventing localized overheating, which is critical for protecting both the heater elements and heat-sensitive fluids.

Flow Configurations

Vertical (Counter-Flow)

Inlet

Outlet

Ideal for preventing air pockets and ensuring elements remain submerged.

Horizontal

Inlet

Outlet

Common configuration, ensure outlet nozzle is oriented upwards to purge air.

Anatomy of a Circulation Heater

Understanding the components is essential for proper specification. Each part is selected based on the application's demands for temperature, pressure, and corrosion resistance.

- Heating Element Assembly: The heart of the unit (e.g., WATROD™, FIREBAR®), consisting of resistance wire, compacted MgO for insulation, and a protective outer sheath.

- Pressure Vessel: The chamber containing the fluid, made from carbon steel, stainless steel, or other alloys, often built to ASME code for safety.

- Mounting Flange: The method of attaching the heater assembly to the vessel, dictating power and pressure capabilities.

- Inlet/Outlet Nozzles: Connection points (threaded or flanged) for process piping.

- Terminal Enclosure: A NEMA-rated housing (e.g., NEMA 4, NEMA 7 for hazardous locations) protecting electrical connections.

- Thermal Insulation & Jacket: Minimizes heat loss and protects personnel, typically high-density insulation with a steel jacket.

- Controls & Sensors: Thermocouples or RTDs for precise process control and high-limit safety protection.

Table 1: Component & Material Selection Guide

| Application/Fluid | Sheath Material | Vessel/Flange Material | Typical Watt Density (W/in²) |

|---|---|---|---|

| Clean Water | Copper, Incoloy® | Carbon Steel | 48-60 |

| Deionized Water | 316 Stainless Steel | 316 Stainless Steel | 60 |

| Light/Medium Oils | Steel, Incoloy® 800 | Steel | 16-23 |

| Heavy Fuel Oils | Steel | Steel | 8 |

| Caustic Solutions | Incoloy®, 304/316 SS | Stainless Steel | 20-25 |

| Air & Process Gases | Incoloy® 800/840 | Steel or SS | 23-25 |

Choosing Your Heater: Screw Plug vs. Flanged Designs

The first major specification decision is between a screw plug and a flanged design. This choice dictates the heater's power, pressure rating, and suitability for various **flange heater applications**.

Table 2: Screw Plug vs. Flanged Heaters

| Feature | Screw Plug Heaters | Flanged Heaters |

|---|---|---|

| Mounting | Threaded NPT plug | Bolted ANSI flange |

| Power Range | Lower (kW range) | High (up to 1+ MW) |

| Pressure Rating | Lower to moderate | High (ANSI class rated) |

| Ideal Use Cases | Small tanks, labs, auxiliary equipment | Large-scale industrial processes (Oil & Gas, Chemical) |

| Key Advantage | Compact, cost-effective | High power, extreme durability |

A Practical Guide to Sizing and Watt Density Calculation

Properly sizing a heater is a critical engineering task. An incorrectly sized unit can lead to inefficiency, fluid damage, or premature failure. This section provides the formulas, examples, and tools for the Process Engineer who needs to get it right.

1. The Core Formula for Liquids

Use the following formula to determine the power needed to achieve your desired temperature rise:

2. Calculation Example: Heating Water

Let's calculate the power required to heat **40 GPM** of water from **60°F** to **100°F**. For water, Specific Gravity and Specific Heat are both **1**.

kW = (40 × 40 × 8.345) / 3412

kW = 13352 / 3412

kW ≈ 3.91 kW

3. The Importance of Watt Density Calculation

This is arguably the most critical factor for heater longevity and fluid integrity. A proper **watt density calculation** involves assessing the power output per square inch of the element's surface.

- Too High: Can cause fluid breakdown (coking) or rapid element burnout.

- Too Low: Safer for the fluid and extends heater life, but results in a physically larger, more expensive unit.

Consult Table 1 for typical values or for expert guidance on this crucial trade-off.

Quick Heater Selection Guide & Tools

Use this simplified flow chart for a preliminary model recommendation, then use the integrated **Online Thermal Power Calculator** to refine your power requirements. For final selection, always consult with an Elekheat engineer.

Quick Selection Flow Chart

1. Fluid Type

Water, Oil, Gas, Corrosive?

2. Process Needs

High/Low Temp? High/Low Flow?

3. Recommendation

Low Flow → Screw Plug

High Flow/Pressure → Flange Heater

Online Thermal Power Calculator

Required Power: kW

Control & Electrical Systems

For high-power heaters, simply switching the full load on and off is inefficient and mechanically stressful. Electrical staging is used for precise control. The heater's elements are divided into multiple circuits, which are energized sequentially by a controller to closely match the process heat demand.

Electrical Staging Schematic

A controller sends signals (dashed lines) to energize each power circuit in stages, precisely modulating the heat output.

High-Stakes Flange Heater Applications

Enhancing Efficiency from Upstream to Downstream

In Oil & Gas, uptime and safety are paramount. Heaters are used for crude oil pre-heating to lower viscosity, hydrate prevention in pipelines, and as a **thermal fluid heater** for regeneration gas. These are critical **flange heater applications** where high power and robust construction are essential.

Precision Heating for Critical Reactions

The chemical industry demands precise temperature control. Heaters are vital for jacketed reactors, catalyst activation, and safely heating corrosive specialty chemicals with materials like Incoloy®.

Ensuring Reliability in Critical Systems

Reliability is key in power generation. Heaters are used for boiler feedwater preheating, maintaining turbine lube oil viscosity, and ensuring genset engines start reliably in any condition.

Upholding Purity and Safety

In these regulated industries, sanitation is crucial. Sanitary stainless steel heaters are used for Clean-in-Place (CIP) systems, pasteurization, and generating Water for Injection (WFI).

Application Case Studies

Oil Refinery: Solving a Viscosity Challenge

The Problem: A major refinery experienced significant operational slowdowns during winter as the viscosity of heavy crude oil in transfer lines increased, straining pumps and risking cavitation.

Our Solution: We worked with their engineers to deploy a distributed network of 36 high-power flange heaters with explosion-proof NEMA 7 enclosures. The installation challenge was integrating these units into their existing SCADA control system for centralized monitoring. Our team provided on-site support to ensure seamless integration.

The Result: The system successfully maintained optimal fluid viscosity, cutting related energy costs by 22% and completely eliminating winter-related pump downtime.

Chemical Plant: Precision Catalyst Heating

The Problem: A specialty chemical producer was struggling with inconsistent batch quality due to poor temperature control during a critical catalyst activation phase. The process required a very narrow temperature window and used a highly corrosive fluid.

Our Solution: We engineered a custom **thermal fluid heater** using Incoloy® 800 for all wetted parts and integrated a multi-stage SCR control panel. This provided extremely fine-tuned power modulation, holding the process temperature within ±1°F.

The Result: The precise control led to a 15% increase in reaction yield and a dramatic improvement in product consistency, paying for the system within nine months.

Food Processing: Accelerating Sterilization

The Problem: A beverage bottling plant needed to reduce downtime associated with their Clean-in-Place (CIP) system. Their existing steam-based system was slow to reach the required sterilization temperature.

Our Solution: We replaced their steam heat exchanger with two high-efficiency, sanitary **inline circulation heaters**. Built with polished 316L stainless steel, the units met strict food-grade standards. The fast-acting electric elements provided near-instantaneous heat.

The Result: The new system reduced the time to reach sterilization temperature from 25 minutes to just 10 minutes, cutting the total cleaning cycle time by 30% and significantly increasing daily production capacity.

A Maintenance Manager's Guide to Reliability

Diagnosing Common Issues

- Problem: System Not Reaching Temperature. Check for proper fluid flow, verify control panel settings and sensor function, and inspect elements for fouling.

- Problem: Heater Tripping High-Limit. This indicates an over-temperature condition. The most common cause is low or no fluid flow. Immediately check pumps and for blockages in the line.

Preventing Fouling, Coking, and Burnout

- Fouling/Coking: This buildup on elements acts as an insulator, causing them to overheat. It's caused by incorrect (too high) watt density for the fluid. Ensure the heater was specified correctly.

- Element Burnout: Often caused by operating the heater with insufficient fluid flow or in a dry condition. Always ensure the heater is fully submerged in flowing fluid before energizing.

- Preventive Maintenance: Establish a regular inspection schedule to check for element buildup, especially in hard water or oil applications. Clean elements according to manufacturer recommendations.

Safety & Compliance: Heaters for Demanding Environments

In high-stakes industries, safety is non-negotiable. Elekheat heaters are available with the certifications you need to ensure compliance and mitigate risk.

Hazardous Locations

We provide units with NEMA 7 explosion-proof enclosures and full UL, CSA, and ATEX certifications for facilities with flammable gases or vapors.

Pressure Safety

Our vessels can be designed and built to meet ASME Section VIII Division 1 standards, ensuring the highest level of integrity for high-pressure applications.

Authoritative Standards and Resources

To ensure the highest levels of safety, reliability, and interoperability, industrial heating equipment adheres to standards set by globally recognized organizations. For further technical details, refer to these authorities:

- NEMA (National Electrical Manufacturers Association): Defines standards for electrical enclosures, such as NEMA 4 and NEMA 7, protecting against environmental hazards.

- ASME (American Society of Mechanical Engineers): Sets the standards for pressure vessels (BPVC Section VIII), ensuring mechanical integrity and safety under pressure.

- UL (Underwriters Laboratories): Provides safety certification for electrical components and assemblies, ensuring they meet rigorous safety and performance standards.

Frequently Asked Questions

An immersion heater is a component that heats static fluid in a tank. A circulation heater is a complete, self-contained system with a vessel designed to heat a flowing fluid in a pipeline. The key is system vs. component.

Yes, absolutely. They are frequently used to heat air, nitrogen, natural gas, and other process gases. Material selection and watt density are critical for gas heating applications to prevent overheating.

A low or non-existent flow rate is the most common cause of heater failure. The fluid can't carry heat away from the elements fast enough, causing them to overheat. This can damage the fluid and lead to element burnout. A high-limit temperature sensor is a critical safety feature to prevent this.

Material selection depends on the fluid's corrosive properties and the operating temperature. For example, clean water can use copper sheaths, while deionized water or caustic solutions require stainless steel or Incoloy®. Refer to Table 1 in this guide for general recommendations or contact us for a specific application review.

Why Choose Elekheat for Your Industrial Circulation Heaters?

We are more than a supplier; we are your process heating partner. We leverage our deep engineering expertise to deliver pre-engineered, reliable, and safe heating systems tailored to your application. We understand the entire product lifecycle, from initial design to long-term maintenance.