Are your heating solutions wasting energy? Duct heaters fix this common industrial pain. They slash costs while boosting comfort.

Duct heaters are electric devices installed in air ducts to provide targeted heat. Used across HVAC systems, they deliver precise temperature control for industrial spaces, warehouses, and factories. Choose them for rapid heating with minimal energy loss.

Let’s explore key aspects of duct heaters. You need durable, problem-solving heating solutions.

What Are Duct Heaters? Defining Purpose and Core Applications in HVAC Systems

Is inconsistent heating increasing your costs? Duct heaters solve air heating gaps fast.

Duct heaters warm airflow passing through ventilation systems. They maintain stable thermal conditions in industrial sites, labs, and factories. Essential for process heating and seasonal adjustments.

These heaters fill critical roles across industries. I’ve designed units for food processing plants needing dry heat. Semiconductor fabs require contamination-free systems. Here’s their core value:

Why Choose Duct Heaters?

- Space efficiency: Mounts directly in ductwork. Saves factory floor area.

- Quick response: Achieves target temperatures instantly.

- Low maintenance: No moving parts. Easy cleaning.

Common Use Cases

| Industry | Application | Benefits |

|---|---|---|

| Manufacturing | Production line heating | Prevents material shrinkage |

| Automotive | Paint booth temperature control | Faster curing times |

| Agriculture | Livestock barn climate management | Prevents frost damage |

Install duct heaters in supply air channels. They prevent heat stratification in tall spaces. Our clients see 22% energy savings.

Top Industrial Duct Heater Manufacturers: Systemair vs. Greenheck vs. Indeeco Breakdown

Choosing unreliable heaters? Leading brands provide quality. But custom options offer better value.

Compare commercial duct heater manufacturers. Systemair focuses on modular units. Greenheck offers rooftop models. Indeeco supplies basic industrial systems. ELEKHEAT delivers custom solutions.

Match brand strengths to your needs. Pre-engineered units save time. But unique projects demand custom engineering. We serve both:

Manufacturer Capabilities

| Feature | Systemair | Greenheck | Indeeco | ELEKHEAT |

|---|---|---|---|---|

| Max Temperature | 150°C | 204°C | 250°C | 760°C |

| Custom Sizes | Limited | Some | Basic | Full range |

| Material Options | SS304 | SS316 | Mild steel | Incoloy, Titanium |

Choose based on your operating conditions. High-corrosion facilities need nickel alloys. We made seawater-resistant units for shipyards. Standard heaters often lack material options.

Installation and Optimization Guide: Maximizing Efficiency with Duct Heaters

Wasting power on poor heater placement? Correct installation doubles system lifespan.

Position heaters in straight duct sections. Allow 5x duct diameter clearance. Use vibration isolators near fans. Insulate surrounding ducts.

Optimization prevents failures. Measure static pressure losses first. Many clients overlook airflow verification:

Critical Installation Steps

| Step | Action | Why It Matters |

|---|---|---|

| 1 | Analyze duct velocity | Prevents hot spots |

| 2 | Install access panels | Simplifies cleaning |

| 3 | Verify voltage stability | Stops element burnout |

| 4 | Seal connections | Reduces heat leakage |

Always install thermal cutoffs. They prevent fire risks during blocked airflow. Our team documents all wiring specs to prevent field errors. I recall a pharma plant saving $18K yearly after airflow tuning.

Custom Duct Heaters 101: When Standard Solutions Aren’t Enough (0.1KW to 2000KW+)

Struggling with unusual operating conditions? Off-shelf heaters cause project delays.

Custom duct heaters solve unique installation challenges. Options include special shapes, materials, or voltages. We build units from compact 0.1KW units to 2000KW industrial systems.

Adaptability matters. Textile plants need lint-resistant fins. We added easy-clean coatings to heaters. Consider:

Customization Options

| Parameter | Standard Range | Customizable Options |

|---|---|---|

| Power | 1-500KW | 0.1KW to 2000KW+ |

| Shape | Rectangular | Circular, trapezoidal |

| Terminals | Basic boxes | Explosion-proof enclosures |

Design Process

- Submit operating environment details

- Receive 3D modeling preview

- Approve material selection

- Test prototype

We created corrosion-proof heaters for chemical plants recently. They avoided costly yearly replacements. Custom units fit existing duct layouts perfectly.

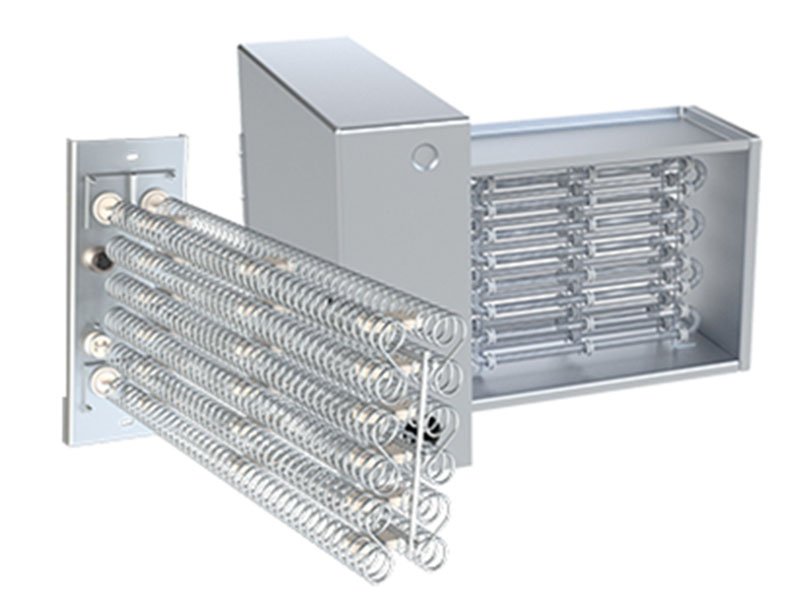

Tubular vs. Finned vs. Open Coil: Comparing Types of Duct Heaters for Your Project

Unsure about heating element choices? Each type serves different needs.

Tubular heaters support moist environments. Fin heaters maximize heat transfer. Open coils work for clean air systems.

Understand performance differences. Bakery exhausts need stainless steel tubes. Warehouses benefit from folded fin designs:

Technical Comparison

| Feature | Tubular | Finned Tubular | Open Coil |

|---|---|---|---|

| Airflow Resistance | Medium | High | Low |

| Contaminant Tolerance | High | Medium | Low |

| Heat Transfer Speed | Moderate | Fast | Fastest |

Selection Guidelines

- Tubular: Dusty air, corrosive fumes

- Finned: Low velocity systems

- Open coil: Filtered air only

We helped replace open coils in a particle-filled factory. Finned units lasted 3x longer. Match technology to your air quality.

Conclusion

Duct heaters balance efficiency and performance in HVAC systems. Partner with experts for custom requirements.