01 Introduction to Cartridge Heaters

Cartridge heaters, also known as heating cartridges or single-end heaters, have a long history in the electric heating industry and are designated as M3 models in China. Since the widespread adoption of heating tubes in China during the late 1990s, their designs have diversified significantly. In Southern China, these single-lead heaters for molds are commonly referred to as "single-head heating tubes" or "single-end heating tubes."

◇ History and Features

Renowned for their simplicity, mechanical robustness, exceptional thermal efficiency, safety reliability, and ease of installation, cartridge heaters offer an extended service lifespan. Additional advantages include energy efficiency, eco-friendliness, lightweight design, and effortless disassembly, enabling superior performance across diverse applications.

02 Wiring Structures of Cartridge Heaters

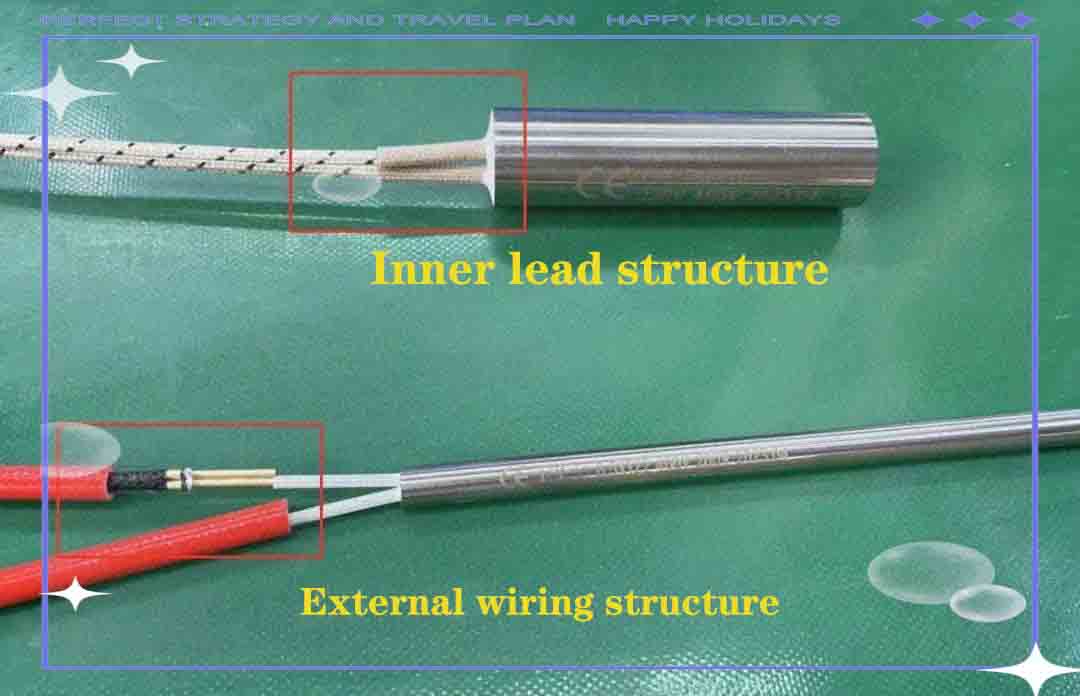

Let’s delve deeper into the wiring configurations of cartridge heaters. Within the electric heating industry, these components typically feature two distinct wiring structures:

- External Wiring (Crimped Construction)

- Internal Wiring (Swaged Construction)

The differences between these configurations are clearly visible in the physical diagrams below.

◇ Overview of Crimped vs. Swaged Construction

As critical heating elements, the choice of wiring structure significantly impacts functionality. Each type delivers unique advantages:

| Structure | Key Characteristics | Visual Differentiation |

|---|---|---|

| Crimped | External terminal connections | ![Crimped_Diagram] |

| Swaged | Embedded internal connections | ![Swaged_Diagram] |

◇ Manufacturing Process & High-Temperature Lead Materials

Crimped Construction:

- Process: Lead rods and wires connect externally via crimped terminals.

- Insulation: Fiberglass sleeves encapsulate joints to prevent bending damage and enhance insulation.

- Lead Material: Stainless steel wires (stable below 350°C) with ≥200°C heat resistance.

Swaged Construction:

- Process: High-temperature leads weld internally to resistors before sealing with ceramics/encapsulants.

- Complexity: More intricate process requiring extended production time.

- Lead Material: Pure nickel wire or Teflon-nickel wire (≥800°C resistance), ensuring:

- Zero oxidation/carbonization for >5 years

- Capability to sustain ultra-high power density (>25W/cm²)

Performance Comparison:

| Feature | Crimped Construction | Swaged Construction |

|---|---|---|

| Lead Material | Stainless steel wire | Nickel-core high-temp wire |

| Max. Temp Resistance | ~350°C (degrading rapidly) | ~800°C (stable) |

| Oxidation Resistance | Low (prone to carbonization) | Exceptionally High |

| Bending Durability | Moderate | Excellent (no crimp points) |

| Lifetime | Shorter | 5+ years (no carbonization) |

| Power Density Support | Limited | >25W/cm² |

03 Structural Selection Recommendations

When selecting a single-end heater structure, critically evaluate the following aspects:

-

Temperature Requirements

- ≤350°C: Crimped construction (cost-effective)

-

350°C: Swaged construction (mandatory)

-

Power Density Needs

- Projects requiring >25W/cm² must adopt swaged construction.

-

Lifetime Expectations

- For longevity beyond 5 years with minimal degradation, swaged construction using nickel-core wires is optimal.

-

Flexibility Requirements

- Applications needing frequent bending benefit from swaged leads without crimp points.

✅ Key Takeaway: Prioritize swaged construction in high-temperature or high-reliability scenarios. Opt for crimped variants only in low-cost, low-temperature environments where power density remains under 25W/cm².