A Complete Guide to Industrial Heating Elements

The hardworking, unseen heroes in countless manufacturing processes. This guide breaks down everything you need to know about what they are, how they work, the different types available, and how to choose the perfect one for your needs.

What Is an Industrial Heating Element?

At its heart, an industrial heating element is a device that efficiently converts electrical energy into heat. Unlike heaters in home appliances, industrial models are built to be incredibly robust, reliable, and safe for use in tough environments with high temperatures, corrosive chemicals, and non-stop operation.

How Do They Work? The Science of Joule Heating

The magic behind almost every electric heater is a principle called Joule heating (or resistive heating). Discovered in 1840 by James Prescott Joule, it describes how heat is generated when an electric current flows through a material that resists it.

Think of it like friction: as electrons are pushed through the material, they collide with atoms, causing them to vibrate. This increased vibration is what we feel as heat. At the point of use, this process is nearly 100% efficient, meaning all the electricity is converted directly into thermal energy.

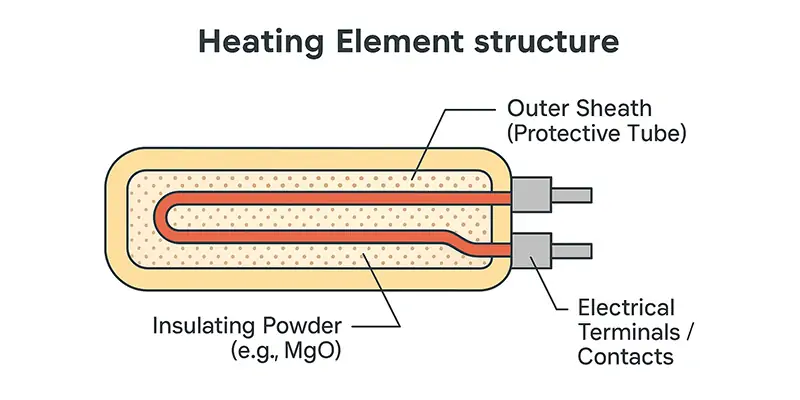

Anatomy of a Heater: The 3 Key Components

An industrial heater is a system of three critical parts working together: the core, the sheath, and the insulator. The performance of the heater is only as good as its weakest link.

1. The Resistive Core (The Engine)

This is where the heat is generated. The material used for the core depends on the required temperature and environment.

- Nichrome (Nickel-Chromium): The long-time industry standard, great for general use up to about 1250°C.

- Kanthal® (FeCrAl): A step up from Nichrome, these alloys can operate at higher temperatures (up to 1425°C) and can last up to four times longer.

- Refractory Metals (Tungsten, Molybdenum): Used for extreme temperatures (up to 2800°C for Tungsten) in vacuum or controlled atmospheres where there is no oxygen.

- Advanced Ceramics (Silicon Carbide, Molybdenum Disilicide): Offer superior performance in corrosive environments and at extremely high temperatures in air.

2. The Protective Sheath (The Armor)

The sheath is the outer layer that protects the internal components from damage and corrosion while transferring heat to the substance being heated. Sheath material is chosen based on temperature and chemical compatibility.

- Steel: A cost-effective choice for non-corrosive materials like oils and waxes.

- Stainless Steel (304, 316, 321): Offers good to excellent corrosion resistance for various water types, food processing, and mild chemicals.

- Incoloy® / Inconel®: Nickel-based superalloys for superior strength and resistance in high-temperature or highly corrosive applications.

- Titanium: A premium choice offering outstanding resistance to aggressive chemicals like acids and seawater where other metals would fail.

- Copper: Excellent for heating clean, potable water due to high thermal conductivity.

3. The Dielectric Insulator (The Go-Between)

Sandwiched between the core and the sheath, the insulator must be a great electrical blocker but also a great heat conductor.

- Magnesium Oxide (MgO): The most common insulator, used as a compacted powder. Its main weakness is that it absorbs moisture (hygroscopic), which can cause heater failure if not properly stored or baked out before use. This is a very common cause of premature failure.

- Mica: A mineral used in flat heaters like strip and band heaters. It has excellent dielectric strength and heat resistance.

Types of Industrial Heating Elements

Heaters come in many shapes and sizes, each engineered for a specific job. Here are some of the most common types.

Tubular Heaters

The most versatile and widely used heaters. They can be bent into almost any shape. Finned tubular heaters have fins added for efficient air and gas heating.

Cartridge Heaters

Designed for concentrated, high-intensity heat. Their performance depends critically on a tight fit; air gaps will cause the heater to overheat and fail quickly.

Band Heaters

These circular heaters clamp around cylindrical parts. Ceramic band heaters can improve energy efficiency by 25-30% or more.

Strip Heaters

Flat heaters designed to be clamped onto surfaces or used as air heaters in ovens. Finned versions are available for more efficient air heating.

Immersion Heaters

Designed for direct submersion in liquids, making them nearly 100% efficient. Common types include Flanged, Screwplug, and portable Over-the-Side heaters.

Flexible Heaters

Made from materials like silicone rubber, these thin heaters can conform to irregular surfaces. Ideal for freeze protection, medical equipment, and 3D printer beds.

Circulation Heaters

Also known as in-line heaters, these are self-contained systems for precise on-demand heating of flowing liquids and gases.

How to Choose the Right Industrial Heater

Selecting the right heater is a critical decision. A cheap heater that fails frequently can be far more expensive in the long run. Ask these key questions:

- What temperature do you need? This is the primary factor that determines the materials for the heater's core and sheath.

- What are you heating? The medium dictates the required watt density (power per surface area). Water can handle a high watt density, while thick oil needs a low watt density.

- What is the operating environment? The sheath material must resist corrosion from the liquid. The atmosphere is critical for furnace heaters.

- What are the physical and electrical constraints? The heater must fit your equipment and match the available voltage (e.g., 120V, 240V, 480V).

Table 1: Comparative Performance of Heater Types

| Heater Type | Max. Op. Temp. | Watt Density | Heat-Up Speed | Temp. Uniformity | Relative Lifespan | Relative Cost |

|---|---|---|---|---|---|---|

| Tubular | Medium-High (~870°C) | Low to High | Medium | Good | Long | $$ |

| Cartridge | High (~760°C) | Very High | Fast | Good (Localized) | Medium-Long | $$$ |

| Strip (Mica) | Medium (~480°C) | Low to Medium | Medium | Good | Medium | $ |

| Band (Mica) | Medium (~480°C) | Medium | Good | Medium | $$ | |

| Band (Ceramic) | High (~760°C) | High | Medium-Fast | Excellent | Long | $$$ |

| Immersion | Medium-High (~870°C) | Low to High | Fast (in liquid) | Excellent (in liquid) | Long | $$-$$$$ |

| Flexible (Silicone) | Low (~220°C) | Low to Medium | Fast | Excellent | Medium | $$$ |

| Flexible (Polyimide) | Low (~200°C) | Low to Medium | Very Fast | Excellent | Medium | $$$$ |

| Ceramic (SiC/MoSi₂) | Very High (>1800°C) | High | Fast | Excellent | Very Long | $$$$$ |

Note: Values are typical. Cost is relative and for general comparison purposes only.

Table 2: Chemical Compatibility Guide

| Solution | 304 SS | 316 SS | Incoloy® | Titanium | Copper | Steel | PTFE |

|---|---|---|---|---|---|---|---|

| Acids | |||||||

| Acetic Acid | C | B | B | A | X | C | A |

| Chromic Acid (≤10%) | X | X | X | A | X | X | A |

| Hydrochloric Acid | X | X | X | C | X | X | A |

| Hydrofluoric Acid | X | X | X | X | X | X | A |

| Nitric Acid (dilute) | B | A | A | A | X | C | B |

| Sulfuric Acid (≤10%) | C | B | A | B | X | C | A |

| Alkaline Solutions | |||||||

| Alkaline Cleaners | A | A | A | A | C | A | A |

| Ammonium Hydroxide | B | B | A | A | C | B | A |

| Caustic Soda (NaOH) | A | A | A | B | X | A | A |

| Potassium Hydroxide | A | A | A | B | X | A | A |

| Water | |||||||

| Deionized/Distilled Water | C | A | A | A | C | C | A |

| Process/Industrial Water | B | A | A | A | B | C | A |

| Potable/Clean Water | B | B | A | A | A | B | A |

| Seawater/Salt Water | X | C | B | A | X | X | A |

Rating System: A - Good/Excellent; B - Fair; C - Poor; X - Unsuitable.

Disclaimer: This is a general guide. Always consult a materials expert for your specific application.

Maintenance and Safety Best Practices

The life and reliability of a heater depend on proper use and maintenance. Most failures are caused by application errors, not product defects.

Tips for a Longer Heater Life

- Prevent Overheating: This is the #1 cause of failure. Ensure correct watt density and a tight fit for cartridge heaters. Regularly clean immersion heaters.

- Avoid Contamination: Keep terminals clean and dry. Moisture is a leading cause of electrical shorts at startup.

- Perform Electrical Tests: Periodically use a megohmmeter to test for moisture contamination before it causes a catastrophic failure.

- Inspect and Clean Regularly: Visually check for corrosion or damage. Keep elements clean for efficient heat transfer.

Essential Safety Rules

- Lockout/Tagout: Always disconnect power before any installation or maintenance.

- Use Correct Wiring: All electrical work must be done by qualified personnel according to code.

- Control Your Temperature: Use a primary controller and an independent high-limit controller to prevent dangerous runaway temperatures.

- Wear PPE: Use appropriate Personal Protective Equipment, including heat-resistant gloves and safety glasses.

The Future of Industrial Heating

The world of industrial heating is getting smarter and cleaner, driven by sustainability and Industry 4.0.

- Electrification: Companies are increasingly switching from fossil fuel heating to electric heating to cut carbon emissions. When powered by renewable energy, electric heating offers a path to zero-emission manufacturing.

- Smart Controls & IoT: Heaters are becoming intelligent devices. By equipping them with sensors connected to the Internet of Things (IoT), companies can monitor them remotely, predict failures before they happen using AI, and optimize energy use in real-time.