Are you struggling with slow heating times or leaking tanks in your facility? Inefficient industrial heating leads to high energy bills and dangerous downtime. You need a reliable solution that handles high pressure while delivering heat exactly where it is needed.

An industrial flange heater works by converting electricity into heat through resistance wires inside metal tubes. These tubes are welded to a flange and submerged in a tank. Heat moves from the wire to the fluid via conduction and convection, while sensors and PID controllers maintain precise temperatures for safety and efficiency.

Understanding how these powerful tools work is the first step toward optimizing your production line.

How does the resistance wire create heat?

Do you know why the heating elements turn hot the moment you flip the switch? The process starts deep inside the metal sheath, where electricity meets resistance to create thermal energy.

The core of a flange heater consists of nickel-chromium resistance wires. When an electric current passes through these wires, they generate heat based on Joule’s Law. High-purity magnesium oxide (MgO) powder surrounds the wire, acting as a thermal bridge that moves heat to the outer tube while providing electrical insulation.

The Magic of Joule Heating

In our 25 years of experience at ELEKHEAT, we have seen that the quality of the internal components determines the heater's life. The resistance wire behaves like a spring. When electricity flows, the wire resists the movement of electrons. This friction creates heat.

The magnesium oxide powder is the unsung hero here. It must be packed very densely. If there are air gaps, the wire will overheat and "burn out." This is why we use high-pressure filling machines in our 48,00 sqm plant to ensure the MgO is solid and efficient.

Why Material Selection Matters

The outer "sheath" or tube must match your environment. If you heat water, copper or stainless steel works. If you heat corrosive chemicals, you need specialized alloys like Incoloy.

| Sheath Material | Best Used For | Temperature Limit | Pros |

|---|---|---|---|

| Copper | Clean Water | 350°F | High heat transfer, low cost |

| Steel | Oils, Gases | 750°F | Durable, good for heavy oils |

| Stainless Steel | Process Water, Food | 1200°F | Corrosion resistant, hygienic |

| Incoloy | Corrosive Acids | 1600°F | Extremely high heat resistance |

How does heat move from the tube to your liquid?

Generating heat is only half the battle. The real goal is to get that heat into your water, oil, or gas without wasting energy. How does a metal tube "push" heat into moving fluids?

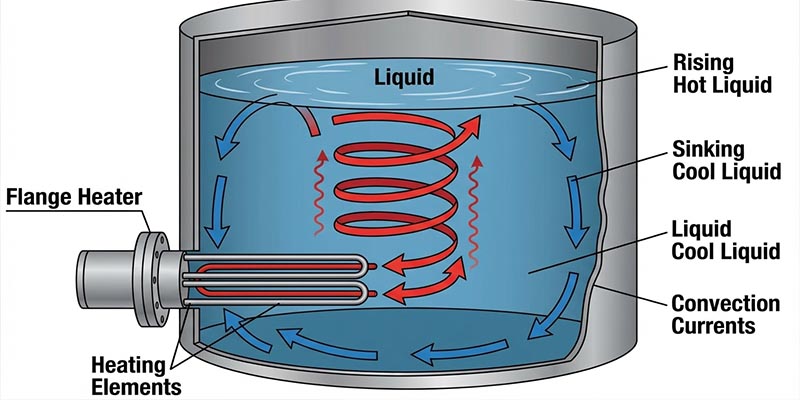

Flange heaters use conduction and convection to transfer energy. The hot metal tube touches the liquid (conduction), and as the liquid warms up, it moves away to let cooler liquid take its place (convection). This creates a continuous thermal loop that heats large volumes quickly and evenly.

Creating a Thermal Loop

When we design a heater for a client, we calculate the "watt density." This is how much heat is coming off every square inch of the tube. If the watt density is too high for the liquid, the liquid might "burn" or "carbonize" on the tube surface. This creates a crust that blocks heat and eventually kills the heater.

We focus on balancing the flow of the liquid with the power of the heater. In a storage tank, the hot fluid rises, and the cold fluid sinks. By placing the flange heater near the bottom, we utilize natural convection to ensure the entire tank stays at a uniform temperature.

Three Ways Heat Travels

While conduction is the main driver, radiation also plays a small role in gas heating applications.

| Method | Role in Flange Heaters | Efficiency Level |

|---|---|---|

| Conduction | Direct contact between tube and liquid. | High |

| Convection | Fluid movement carrying heat away. | Very High |

| Radiation | Infrared heat for high-temp gases. | Moderate |

How does the heater maintain exact temperatures?

Too much heat can ruin your product, while too little heat can stop your production line. How does a "dumb" piece of metal stay at a "smart" and precise temperature?

Precision is achieved through temperature sensors and PID controllers. A sensor (like a thermocouple) sits inside the liquid or on the heating element. It sends data to a digital PID controller, which acts like a smart throttle, turning the power on or off to maintain the exact set point without overshooting.

The "Smart Driver" Analogy

Think of a PID controller like a driver in a car. If the driver sees a red light, they start braking early so the car stops exactly at the line. A simple thermostat just hits the brakes at the last second, making the car lurch forward.

At ELEKHEAT, we often integrate "over-temperature" sensors directly onto the heating bundle. This is a safety backup. If the main controller fails and stays "on," the over-temp sensor triggers a hard shut-off. This prevents the heater from melting or causing a fire.

Precision vs. Traditional Control

Industrial buyers often ask why they should invest in better control systems. The answer is fuel savings and product consistency.

| Control Type | Accuracy | Best For | Risk Level |

|---|---|---|---|

| Mechanical Thermostat | +/- 10°C | Simple water tanks | High (Overshooting) |

| Digital PID | +/- 1°C | Chemical processing | Low (Very Stable) |

| PLC Integrated | +/- 0.5°C | Large scale automation | Lowest (Advanced) |

Why is the flange design critical for safety and sealing?

High-pressure industrial tanks are like giant pressure cookers. If the seal fails, the results can be catastrophic. How does a flange heater stay leak-proof under massive pressure?

The flange acts as a heavy-duty structural seal. Multiple heating elements are argon-arc welded into a standard metal flange plate. This plate is then bolted to a matching nozzle on your tank with a high-grade gasket in between, creating a leak-proof barrier that can withstand hundreds of PSI.

The "Gatekeeper" of Your Tank

The flange isn't just a mount; it is a safety device. We use standard sizes (like ANSI or DIN) so that our heaters fit perfectly into your existing infrastructure. The welding must be perfect. At our plant, we use robotic welding to ensure there are no microscopic holes where gas or liquid could leak into the electrical box.

We also consider the "Cold Section." This is the part of the heater that goes through the flange. We design this area to stay cool so it doesn't damage the gaskets or the external electrical wiring. It is all about protecting the connection points.

Matching Flange Specs to Environment

Choosing the right flange material is just as important as the heater itself.

| Pressure Rating | Flange Material | Typical Application |

|---|---|---|

| 150 lbs | Carbon Steel | Low-pressure oil tanks |

| 300 lbs | 304 Stainless Steel | Medium-pressure steam |

| 600+ lbs | 316 Stainless Steel | High-pressure chemical reactors |

Conclusion

An industrial flange heater is a "smart" high-pressure tool that turns electricity into heat, moves that heat efficiently into fluids, and controls the process with extreme precision. It is the heart of many industrial thermal systems.

At ELEKHEAT, we specialize in 100% custom-built flange heaters designed for your specific liquid, pressure, and temperature needs. Don't risk your production on a "one-size-fits-all" solution—let's build something that lasts.