Choosing the wrong industrial heater leads to leaks, lost power, and expensive downtime. You cannot afford to guess which mounting style matches your tank or pressure requirements.

The main difference lies in application scale: Flange heaters are for high-power, large-scale industrial tanks requiring heavy-duty bolting. Screw plug heaters are for smaller vessels where the heater is "screwed in" like a giant bolt. For high pressure (>6 bar) and massive heat, choose flange; for compact, low-cost needs, choose screw plug.

Understanding these two heaters is the first step to a reliable heating system.

What is the Main Difference in Size and Installation?

You might pick a heater that is too big for your tank or too small for your heat needs. This mistake forces you to modify your equipment, which costs time and money.

Screw plug heaters act like a "bottle cap" for small tanks, while flange heaters act like a "pot lid" for massive boilers. The screw plug is thin and nimble, while the flange is broad and heavy-duty.

The "Boiler Warmer" vs. The "Bucket Heater"

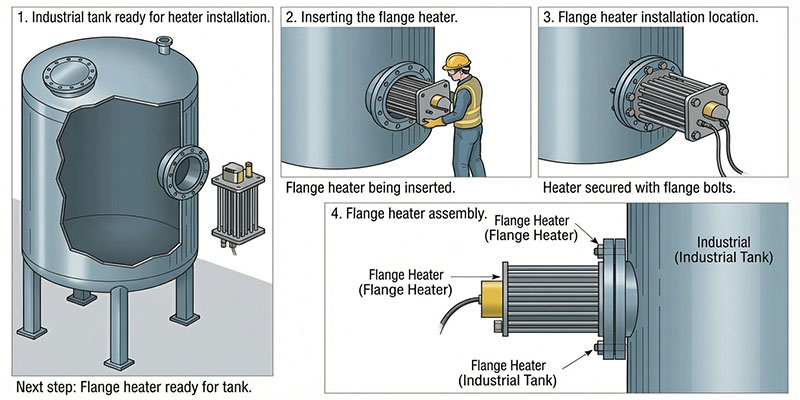

At ELEKHEAT, we often give these heaters nicknames to help our clients understand their scale. We call the flange heater the "Boiler Warmer." It features a large circular plate with many bolt holes. You "thump" it onto the side of a tank and bolt it down. It is a major installation.

We call the screw plug heater the "Bucket Heater." It looks like a giant version of the immersion rods used in homes. It has a threaded hex head. You simply drill a hole, tap the threads, and "zip" it in with a wrench. It fits into small "bottle-neck" openings easily.

Why Custom Bending Matters

In our 25 years of manufacturing, we have seen that space is often tight inside industrial machines. If you use a screw plug heater, you are limited by the diameter of the screw. You can only fit a few U-shaped tubes through that small hole. With a flange heater, we can bundle dozens of heating elements together. Because the flange opening is wide, we can create complex "bends" to maximize the surface area without the tubes touching each other.

Installation Requirements Comparison

| Feature | Flange Heater | Screw Plug Heater |

|---|---|---|

| Visual Look | A "radiator" bundle on a plate | A "bundle of sticks" on a bolt |

| Hole Type | Large "Pot Lid" opening | Small "Bottle Cap" thread |

| Mounting | 8 to 12 heavy bolts | Single threaded twist |

| Space Used | Large footprint on tank wall | Very small footprint |

Pressure and Power: Which Heater Can Handle the Load?

Using a screw plug heater in a high-pressure chemical tank is a recipe for disaster. The threads can fail, causing dangerous leaks. Likewise, using a flange for a tiny water tank is an expensive over-design.

Flange heaters handle extreme pressure (up to 40 bar) and massive power (hundreds of kilowatts). Screw plug heaters are best for low-pressure (under 6 bar) and lower power needs (under 30 kW).

Handling the Heavy Lifting

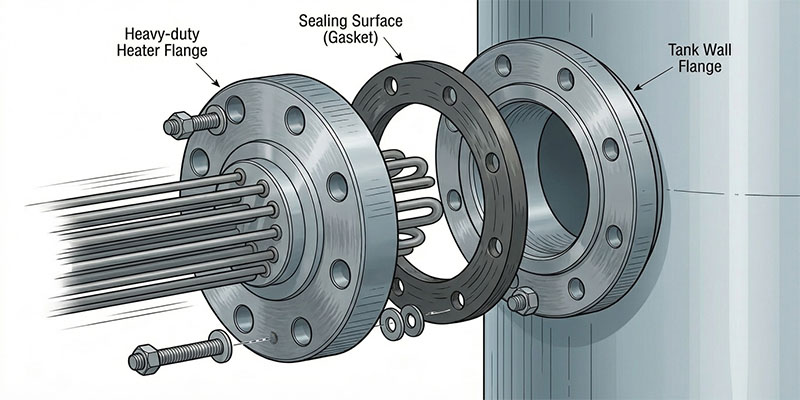

If you have a 200-cubic-meter tank of thermal oil, you need a flange heater. Why? Because you need roughly 240 kW of power to move that temperature from 20°C to 250°C. A screw plug heater simply cannot hold enough heating elements to reach that wattage. At ELEKHEAT, we build these flanges to industrial standards like ANSI or DIN. This ensures that the seal remains tight even when the liquid is boiling and the pressure is rising.

The Limits of Threads

Screw plug heaters rely on "NPT" or "G" threads. These threads are great for sealing water in a pipe, but they have limits. When you go above 6 bar of pressure, the threads begin to "sweat." This means tiny amounts of liquid leak out. If you are heating a food product, like 500 liters of milk, a screw plug is perfect. It provides the 18 kW you need, and the pressure is low enough that the threads stay bone-dry.

Performance and Technical Specifications

| Spec | Flange Heater | Screw Plug Heater |

|---|---|---|

| Power Capacity | 50 kW to 500+ kW | 3 kW to 30 kW |

| Pressure Limit | 10 to 40 bar (High) | 1 to 6 bar (Low) |

| Sealing Method | Gasket + Bolted Pressure | Thread Sealant / O-ring |

| Best For | Large industrial boilers | Small sterilization tanks |

Maintenance and Cost: Which Choice Saves More Money?

A cheap heater becomes expensive when it breaks every month. You must consider how easy it is to clean the heater and how much it costs to buy the unit in the first place.

Screw plug heaters are much cheaper to buy but harder to maintain if the tank is crowded. Flange heaters cost more upfront but allow for "easy access" maintenance and much longer lifespans in dirty environments.

Cleaning and Replacement

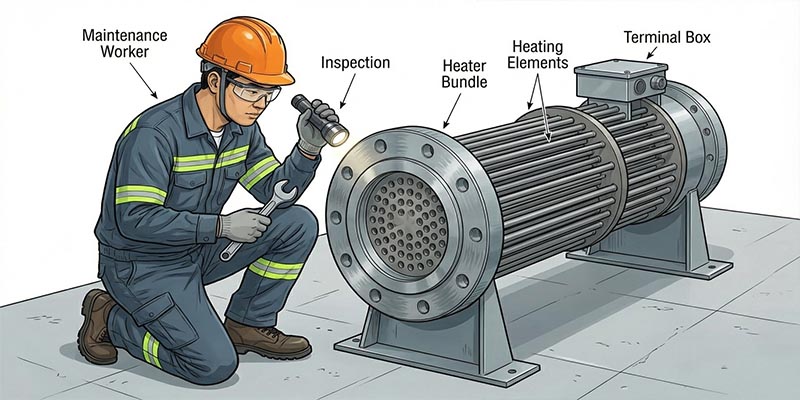

I always tell our clients: "Think about the day you have to fix it." If you have thick oil or hard water, minerals will build up on the tubes. To clean a flange heater, you "un-lid" the tank. The elements come out with plenty of space between them. You can scrub them easily.

With a screw plug heater, the tubes are bundled very tightly together to fit through the small hole. If one tube fails or gets covered in scale, it is almost impossible to clean between the gaps. Often, you simply have to throw the whole unit away and buy a new one. However, because the screw plug is simple to make (one nut and a few tubes), the replacement cost is often 50% lower than a flange heater.

The True Cost of Downtime

If your factory stops for four hours because a heater leaked, you lose more money than the cost of the heater. We advise our high-volume clients to invest in flange heaters. The thick flange plate acts as a heat sink and provides a much more stable environment for the heating elements. While the initial investment in materials, the flange disk, and the labor is higher, the "cost per year of operation" is usually lower with a flange.

Cost and Maintenance Comparison

| Factor | Flange Heater | Screw Plug Heater |

|---|---|---|

| Initial Price | Higher (Materials + Labor) | Lower (Standardized parts) |

| Repair Ease | Easy (Plenty of space) | Difficult (Tight bundle) |

| Durability | Very High | Moderate |

| Replacement | Replace individual tubes | Replace entire unit |

Conclusion

To choose the right heater, remember this rule: Large tanks, high pressure, and big heat need the "pot lid" flange. Small tanks, low pressure, and low heat need the "screw-in" plug.

Choosing the right mounting style ensures your process stays hot and your floors stay dry. At ELEKHEAT, we specialize in customizing both flange and screw plug heaters to match your specific liquid or gas environment. Contact us today to get a technical drawing for your next project.