Designing an industrial oil heating system is a high-stakes task. One small calculation error can lead to carbon buildup, heater failure, or even hazardous leaks. Our guide provides the technical expertise you need to choose and design the perfect flange heater for your industrial oil applications.

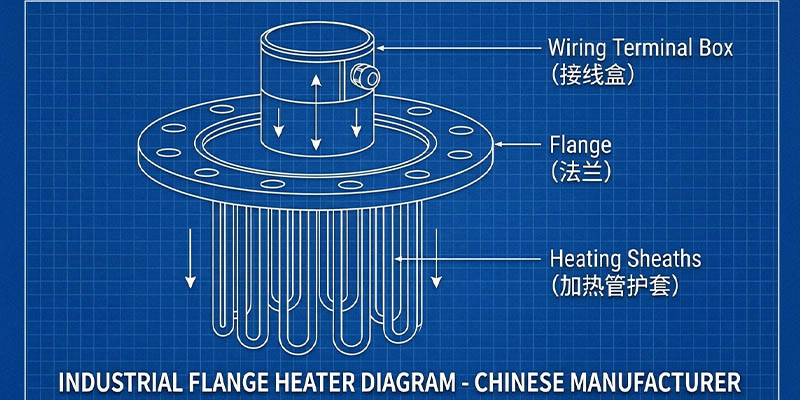

A flange heater for oil heating is an electric immersion heater where hairpin-shaped elements are welded to a metal flange. It provides direct heat transfer to thermal oil. Successful design requires balancing low watt density (usually below 2.3 W/cm²) and high oil flow to prevent carbonization and equipment failure.

Choosing the right design is the difference between constant uptime and expensive maintenance cycles.

What is a Flange Heater for Oil Heating?

Think of your industrial oil heater as a heavy-duty version of a kitchen stove. Instead of a flame heating a pot, we use electricity and a metal flange to heat large volumes of oil.

An oil flange heater consists of electric resistance wires encased in metal sheaths. These sheaths are welded into a circular or square flange, which acts as a "lid" that bolts onto the side of your oil tank or pressure vessel. This design ensures that every bit of heat goes directly into the oil.

How the Magic Happens

Inside the heater, electricity travels through a Nickel-Chromium resistance wire. This wire gets red-hot. The heat moves through high-purity Magnesium Oxide (MgO) powder into the outer metal sheath. At ELEKHEAT, we have spent 25 years refining this internal structure. We ensure the heat moves evenly from the wire to the oil.

Why Oil is Different from Water

Thermal oil is a popular medium because it can reach high temperatures without high pressure. However, oil is sensitive. If you heat it too fast or too intensely, the oil "cracks." This creates a carbon layer on the heater surface. Think of it like burnt food at the bottom of a pan. This carbon layer insulates the heater, causing the internal wire to overheat and eventually burn out.

Performance Comparison Table

| Feature | Flange Heater (Oil) | Steam Jacket Heating |

|---|---|---|

| Heat Transfer | Direct immersion (High efficiency) | Indirect (Lower efficiency) |

| Temperature Control | Very precise (±1°C possible) | Harder to regulate |

| Maintenance | Easy to replace individual units | Requires pipework repair |

| Installation Space | Compact | Bulky (Needs boiler/pipes) |

| Max Temperature | Up to 350°C+ | Limited by steam pressure |

4 Critical Design Mistakes in Oil Heating

Designing for oil requires a different mindset than water. Many procurement managers make the mistake of buying "off-the-shelf" heaters designed for water. This is a recipe for disaster.

The four biggest mistakes in oil heater design are high watt density, low oil flow velocity, lack of dual-safety temperature controls, and ignoring oil expansion. Avoiding these ensures a heater lifespan that is three to five times longer than poorly designed alternatives.

Watt Density: The "Silent Killer"

Watt density is the amount of power emitted per square centimeter of the heater sheath. For water, you can go as high as 10 W/cm². For oil, you must stay low. If your watt density is too high, you will "fry" the oil instantly. At ELEKHEAT, we recommend staying below 2.5 W/cm² for most thermal oils. For heavy or stagnant oils, we go as low as 1.5 W/cm².

The Importance of Flow Velocity

If the oil sits still, it gets too hot. You need a pump to move the oil across the heating elements. We recommend a flow velocity of at least 0.5 meters per second (m/s). This "wipes" the heat away from the element and carries it to your process, keeping the heater sheath cool and the oil healthy.

Dual-Safety Mechanisms

One temperature sensor is never enough. Industrial environments have dust, vibration, and electrical noise. If your primary controller fails, the oil can reach its flash point. We always design heaters with a secondary, mechanical "limit switch" attached directly to the flange. If the temperature exceeds a safe limit, the system cuts power immediately.

Managing Expansion and Pressure

Thermal oil expands by about 15% when heated from room temperature to 300°C. Your system must have an expansion tank. Additionally, the flange seal is critical. We use spiral-wound gaskets with flexible graphite. These can handle the high temperatures and prevent oil from leaking onto your factory floor.

Recommended Watt Density for Different Oils

| Oil Type | Recommended Watt Density | Maximum Surface Temp |

|---|---|---|

| Light Thermal Oil | 2.0 - 2.5 W/cm² | 320°C |

| Heavy Fuel Oil | 1.2 - 1.8 W/cm² | 250°C |

| Vegetable/Food Oil | 1.5 - 2.0 W/cm² | 200°C |

| Lubricating Oil | 1.8 - 2.3 W/cm² | 280°C |

Material Selection for High-Performance Oil Heaters

The materials you choose define the durability of your system. Using the wrong metal can lead to corrosion or structural bending under high heat.

High-performance oil heaters use Stainless Steel 304 or Incoloy 800 for the heater sheaths. The flange itself should be forged from Carbon Steel for standard use or SS316L for corrosive environments. Internally, only high-purity (95%+) Magnesium Oxide powder should be used to ensure electrical insulation.

Selecting the Right Sheath

Most industrial oils work well with Stainless Steel 304. However, if your oil contains additives, acids, or moisture, you need better protection. We often recommend Incoloy 800 for high-temperature applications because it resists oxidation and maintains structural strength at 350°C. Think of the sheath as the "armor" for the resistance wire inside.

The Role of MgO Powder

Magnesium Oxide (MgO) is the "filling" inside the heater tube. It conducts heat while stopping electricity from touching the outer sheath. If the MgO is low quality or becomes damp, the heater will short-circuit. We use high-vibration filling machines to ensure the MgO is dense. Dense MgO means better heat transfer and a longer-lasting heater.

Flange Integrity and Pressure

The flange is the physical connection to your tank. For low-pressure systems, nickel-plated carbon steel is cost-effective. For high-pressure or food-grade applications, we use solid 316L stainless steel. We forge our flanges to be at least 20mm thick to prevent warping when the oil gets hot.

Material Selection Guide

| Component | Standard Application | Corrosive/High-Temp |

|---|---|---|

| Heater Sheath | SS304 | Incoloy 800 / SS316L |

| Flange Material | Carbon Steel (Nickel Plated) | SS316L (Solid Forged) |

| Internal Powder | 90% Purity MgO | 97.5% Purity Re-fused MgO |

| Bending Type | Standard Hairpin | Custom Multi-Leg Bends |

Conclusion

A successful flange heater design for oil heating focuses on three things: low watt density, high oil flow, and high-quality materials. By following these rules, you reduce downtime and save money on energy costs.

At ELEKHEAT, we specialize in custom-engineered solutions for the most demanding industrial environments. Whether you need a standard replacement or a custom heating system for a new project, our 27 years of experience ensure you get the right heater for the job.

Ready to optimize your oil heating system? Contact ELEKHEAT today for a professional technical consultation and quote.```