Household Boiler & Industrial Boiler Manufacturer

ELEKHEAT is a trusted boiler manufacturer in China. We have over 12 years of experience providing the best boiler solutions for different industries.

- Home

- »

- Boiler Heaters

Our industrial boilers

Small boiler

Fuel: Natural gas, LPG, diesel, kerosene, biofuel, electricity

Medium: Hot water, steam

Advantages: Compact design, high thermal efficiency, low emissions, easy installation, intelligent temperature control, energy-saving operation, quiet performance, multiple safety protections

Oil boiler

Fuel: diesel, bio-oil, kerosene, heavy oil, light oil, alcohol, methanol, etc. Medium: hot water, steam, thermal oil, hot air, water vapor dual-use

Advantages: high combustion efficiency, nitrogen oxides ≤30mg/Nm2, high degree of automation, simple operation, stable operation, multiple safety protections

Gas boiler

Fuel: natural gas, city gas, blast furnace gas, coke oven gas, liquefied gas, hydrogen, biogas, etc.

Medium: hot water, steam, thermal oil, hot air, water and steam

Advantages: high combustion efficiency, nitrogen oxides ≤30mg/Nm2, high degree of automation, simple operation, stable operation, multiple safety protections

Vacuum hot water boiler

Fuel: gas, oil, electric heating

Advantages: inspection-free explosion-proof, high thermal efficiency, no scaling and long life, energy saving and environmental protection, accurate control, multi-purpose

Application: suitable for crowded hospitals, schools, hotels, shopping malls, office buildings, commercial

paving, etc.

Biomass boiler

Fuel: Biomass pellets, wood chips, straw bales, bagasse, rice husks, etc. Medium: Hot water, steam, thermal oil, hot air, water vapor dual-use Advantages: High combustion efficiency, clean and environmentally friendly, stable operation, renewable, low cost, policy support

Electric Boiler

Heating method: electrode, resistor, electromagnetic medium: hot water, steam, thermal oil, hot air Advantages: clean and environmentally friendly, high thermal efficiency, no noise, safe and intelligent, small size, flexible space layout, no special fire protection requirements

Coal-fired boiler

Fuel: pulverized coal, briquette, lignite, bituminous coal, anthracite, oil shale, semi-coke, etc. Medium: hot water, steam, thermal oil, hot air, water vapor dual-use

Advantages: simple structure, reliable operation, low fuel cost, low maintenance cost, large heat load, long life

Thermal oil boiler

Fuel: gas, biomass, electric heating, coal, fuel oil

Advantages: high heat transfer efficiency, wide applicable temperature range, high safety, high-temperature control accuracy, stable heat transfer, long life, flexible heat transfer method

Application: suitable for petrochemical, rubber chemical, food processing, pharmaceutical chemical, textile printing and dyeing, papermaking, wood processing and other industries

Steam generator

Fuel: gas, biomass, electric heating, oil, coal

Advantages: fast and pure steam, energy-saving and efficient, strong adjustment ability, high degree of automation, multiple interlocking protection, small size, easy installation

Application: suitable for brewing, disinfection and sterilization, drying of medicinal materials, rubber chemicals, food processing, pharmaceutical chemicals, textile printing and dyeing, washing, wood processing and other industries

ELEKHEAT: Your Premier Boiler Manufacturer and Supplier in China

At ELEKHEAT, we understand that your industrial operations require reliable and efficient heating solutions. As a leading industrial boiler manufacturer, we are committed to providing tailored solutions with precision engineering at every step:

Custom Industrial Boilers Designed for Your Specific Needs

Bespoke Specifications: Customize boiler capacity, pressure ratings, and dimensions to perfectly match your facility’s energy demands.

Fuel Flexibility: Choose from a wide range of fuel options, including natural gas, oil, coal, biomass, and even waste heat recovery systems, to optimize cost-effectiveness and sustainability.

Boiler Type Variety: Select from fire-tube, water-tube, or electric boilers, each engineered for specific applications and efficiency levels.

Control System Precision: Specify advanced control systems for precise temperature management, automated operation, and remote monitoring capabilities.

Material Selection: Determine the optimal construction materials, ensuring longevity and resistance to corrosion in your operating environment.

Specialized Features: Customize your boiler with features like economizers, superheaters, and advanced burner technologies to maximize efficiency and reduce emissions.

Discover the comprehensive range of industrial boiler solutions at ELEKHEAT. Collaborate with our expert team to fine-tune every detail to your exact specifications and benefit from unparalleled technical support. Experience the ELEKHEAT advantage: precision, expertise, and a commitment to excellence, all at your service.

Six reasons to choose us

Based on the real needs of customers, we provide customers with complete solutions and suitable boiler equipment

Engineers calculate the specific size based on the customer's actual needs one by one to ensure economical and practical

Professional engineers develop multiple solutions for customers to compare based on their actual situation.

ISO9001 quality certification, A-level manufacturer, each boiler passes the water pressure and energy efficiency test before leaving the factory

Factory direct sales, with detailed quotation list and clear price of all accessories

Product production strictly adheres to the standards specified by the customer. Products that do not meet the standards will not leave the factory.

ELEKHEAT professional business team, 7*24 hours response, free after-sales service

For more product information, please contact us

Our domestic boiler manufacturing plant

Automatic welding robot

CNC pipe bending machine

CNC cutting machine

CNC Plate Rolling Machine

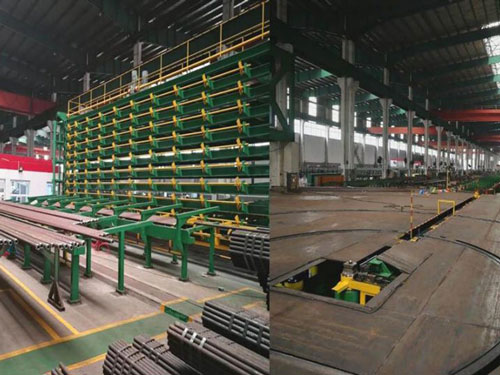

Our Industrial Boiler Manufacturing Plant

Automatic welding robot

CNC pipe bending machine

CNC cutting machine

CNC Plate Rolling Machine

CNC welding machine

Serpentine tube automatic line

Membrane wall production line

Steel pipe shot blasting machine

workshop

workshop

workshop

workshop

Customer Cases

4 tons biomass steam boiler for edible oil plant in Senegal

The user purchased a steam boiler mainly for edible oil processing and production. According to the actual production needs and requirements of the user, our company’s technicians selected a 4-ton biomass steam boiler for it, with a rated design pressure of 1.25 MPa. The maximum steam temperature of the boiler can reach 194 degrees, and a full set of auxiliary equipment is configured for the user, including control cabinets, blowers, induced draft fans, secondary fans, water treatment equipment, cylinders, chimneys, flues, dust collectors, etc.

User Ndir Babacar is particularly satisfied with the operation of our boiler and said: “The biomass boiler works very well. I like it, I like Elekheat.”

8-ton biomass steam boiler for building materials factory in Cote d'Ivoire

The steam boilers produced by ELEKHEAT boilers are mainly used in the country’s agricultural product processing, cotton textile industry, oil refining, chemical industry, building materials and other industries. This time, the company cooperated with the building materials factory in the country. The user saw the actual operation of the biomass boilers produced by our company in other enterprises in the country, so he took the initiative to contact our company. Our project manager and technicians selected an 8-ton biomass steam boiler for the user based on the customer’s actual production needs and fuel conditions. Due to limited local resources, our company specially dispatched technicians to the site for technical support to ensure the smooth installation and operation of the boiler. At present, the project is running very well.

10 tons gas steam boiler for Egyptian textile factory

Egypt’s textile industry is very developed, with many textile factories. Textile production enterprises are generally large-scale and use a large amount of steam. Therefore, the operating costs of gas boilers in textile factories are relatively high. It is very important to choose gas boilers with good energy-saving effects. According to the production needs of users, our company’s technicians selected an environmentally friendly and energy-saving 10-ton gas steam boiler for them. The boiler runs stably and has high thermal efficiency, which can save 5-10% of operating costs.

Indonesian beverage factory 10 tons biomass steam boiler

Boilers are needed in the distillation, extraction, disinfection, drying, maturation and other processes and production links in the beverage factory production process.

Yuanda Boiler’s 10-ton SZL biomass steam boiler not only has high thermal efficiency, but also low operating costs. At the same time, a speed regulating box with a reasonable speed is designed according to the combustion rate, and different numbers of independent wind chambers are set up according to different tonnages to ensure sufficient combustion of the fuel.

Hot topic: How much does a boiler cost?

Due to market price fluctuations, please fill in the form to get today’s quotation

Industrial Boiler Buying Guide: Key Considerations for a Smart Purchase

Selecting the right industrial boiler is a critical decision that impacts operational efficiency, energy costs, and long-term productivity. With numerous options available, navigating the market can be overwhelming. This comprehensive guide simplifies the process, ensuring you make an informed choice tailored to your needs.

1. Understand Your Requirements

Begin by defining your operational needs. Key questions include:

- Application: What processes will the boiler support? (e.g., heating, steam generation, power production)

- Capacity: What is the required output (measured in BTU/hr, pounds of steam per hour, or kW)?

- Fuel Type: Which fuel source aligns with availability, cost, and sustainability goals? (e.g., natural gas, oil, biomass, electric)

Matching these factors to your boiler ensures optimal performance and cost-efficiency.

2. Choose the Right Boiler Type

Industrial boilers fall into two primary categories:

- Fire-Tube Boilers: Compact design, ideal for low- to medium-pressure steam. Suited for small factories or facilities with intermittent demand.

- Water-Tube Boilers: Handle high-pressure steam and large capacities. Common in power plants or industries with continuous heavy usage.

Emerging options like condensing boilers or hybrid systems may offer energy savings but require careful cost-benefit analysis.

3. Prioritize Energy Efficiency

High-efficiency boilers reduce fuel consumption and emissions. Look for:

- Thermal Efficiency Ratings: Aim for models above 90% efficiency.

- Advanced Features: Modulating burners, heat recovery systems, and automated controls optimize performance.

Confirm compliance with regulations like EPA standards or EU Ecodesign Directive for environmental compliance.

4. Evaluate Fuel Compatibility

Fuel choice impacts operating costs and environmental footprint:

- Gas/Oil: Widely available and efficient but subject to price volatility.

- Biomass: Renewable but requires storage space and frequent maintenance.

- Electric: Zero emissions but costly in regions with high electricity rates.

Hybrid systems or dual-fuel boilers provide flexibility if fuel availability fluctuates.

5. Assess Maintenance and Durability

A boiler’s lifespan depends on build quality and upkeep.

- Material Quality: Stainless steel or corrosion-resistant alloys extend durability.

- Ease of Maintenance: Accessible components reduce downtime for cleaning or repairs.

- Warranty: Opt for manufacturers offering ≥5-year warranties and reliable service support.

6. Budget Wisely

Balance upfront costs with long-term savings. While premium models may cost more initially, their energy efficiency and durability often justify the investment. Factor in installation, permits, and retrofitting expenses.

7. Vet Suppliers and Manufacturers

Research reputable brands with proven industry experience. Check:

- Certifications (ASME, ISO)

- Customer reviews and case studies

- Post-purchase support (training, spare parts availability)

8. Plan for Installation and Compliance

Work with certified technicians to ensure safe installation and adherence to local codes (e.g., OSHA, ANSI). Routine inspections and emissions testing may be required.

Final Thoughts

An industrial boiler is a long-term asset, and thorough research is essential. Focus on aligning technical specifications with operational needs, prioritizing efficiency, and partnering with trusted suppliers. By following these steps, you’ll secure a system that drives productivity while minimizing costs and environmental impact.

Pro Tip: Request a site assessment from vendors to tailor recommendations to your facility’s unique conditions.