Are your heaters burning out too fast? You need precise heat in a tight spot, but your current solution fails constantly. This costs you time, money, and production delays.

A heating cartridge is perfect for applications that need intense, localized heat inside a metal hole. Common uses include plastic molds, food processing equipment, 3D printers, and semiconductor manufacturing. Success depends entirely on correct installation.

I've been in this business a long time. Since 2012, I've personally audited dozens of electric heater factories. I walk the entire production line, from the swaging machines and filling towers to the 1000°C tunnel furnaces. Afterwards, I take failed parts, cut them open, and put them under a microscope. I've learned more from looking at magnesium oxide grains and heating wire alignment than from any textbook. I've seen with my own eyes how making the unheated cold end just 5 mm shorter can cut a heater's lifespan by two-thirds.

Why Do My Mold Heaters Keep Burning Out?

Are your plastic molds1 suffering from inconsistent heating? Hot and cold spots ruin parts. And frequent heater burnouts are probably causing expensive downtime for your mold maintenance team.

Heaters in molds often burn out from incorrect installation, not defects. The most common causes are extreme thermal shock2 from water cooling and mechanical stress in the transition zone3 between the hot and cold sections. Extending the cold end is the key to a longer life.

The most valuable lessons come from being on the customer's factory floor. I was at a client's facility, watching them run their injection molding machine. During a 15-minute mold change, the heater cartridge would drop from 220°C down to 30°C as the water cooling kicked in. The heaters were swelling up and failing after only 500 cycles. We tried a few things right there on the line. We ended up extending the cold end by 8 mm and changing the annealing process4 for the tube opening. The result? The cycle life jumped from 500 to 3000 cycles. These are the kinds of real-world fixes you discover in the field. When mold shops send me their failed heaters, my analysis almost always points to the same culprit. About 90% of failures happen in the 10 mm "transition zone" where the hot section meets the cold section.

Key Factors for Mold Heaters

| Parameter | My Recommendation | Reason |

|---|---|---|

| Cold End Length | Extend past water-cooling | Prevents extreme thermal shock during mold changes, which is the primary cause of failure. |

| Fit Tolerance | Snug fit, minimal air gap | Maximizes heat transfer to the mold block. A loose fit creates hot spots on the heater itself. |

| Annealing Process | Use protective atmosphere | Relieves stress in the metal tube at the opening, preventing cracks and swelling from repeated heating and cooling. |

Are Cartridge Heaters Safe for Food Machinery?

Are you worried about heaters contaminating your food products? The wrong heater can release strange smells or fail safety tests. This puts your product quality and brand reputation at risk.

A cartridge heating element is perfectly safe for food machinery when designed correctly. The surface power density5 must be kept low. Also, you must use food-grade materials6 and extend the cold end to prevent overheating and carbonization.

Official standards are a starting point, but they don't tell the whole story. I've participated in discussions for revising standards like IEC 60335 and helped clients with TÜV life-cycle testing. A standard might just say the insulation resistance must be above 1000V. But it won't tell you that a 230V, 2kW heating element cartridge inside a 3mm stainless steel wall will fail if the surface load goes above 12 W/cm². I know this because I ran the test. We ran a test for 6 continuous weeks and burned through 200 sample heaters to get that number. At that high load, the magnesium powder insulation carbonizes in about 200 hours. That's why for food equipment, keeping the surface load under 4 W/cm² is a non-negotiable rule for me. It’s the only way to ensure safety and a long service life.

Food-Grade Heater Specifications

| Component | Specification | Benefit |

|---|---|---|

| Sheath Material | Food-Grade 321 Stainless Steel | Prevents corrosion and ensures no material leaches into the food product. |

| Surface Load | ≤ 4 W/cm² | Avoids internal carbonization of MgO powder, which prevents off-gassing and odors. |

| Cold End Length | Extend ≥ 25 mm from housing | Protects lead wires from high temperatures, ensuring long-term electrical safety and reliability. |

Do 3D Printers Need Special Cartridge Heaters?

Is your 3D printer failing to produce strong parts? If your print head temperature fluctuates wildly, you get poor layer adhesion. This is often caused by a poorly designed heater.

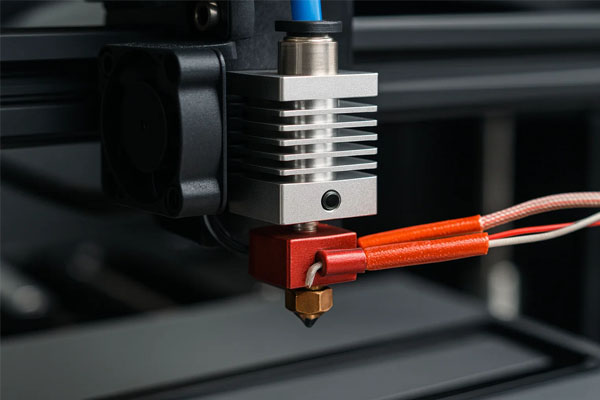

Yes, 3D printers7 use a very specific micro heating cartridge8. The key is not the power, but the precise construction. The heating coil must stop just short of the tube's end to create a stable temperature zone for the sensor.

The hot end of a 3D printer is a great example of a specialized application. Here, we typically use a tiny heat cartridge, maybe 6 mm in diameter and 20 mm long. The power is surprisingly low, often just 30 or 40 watts. The most critical design feature is internal. I always tell my engineers that the heating wire winding must stop exactly 2 mm before the tube opening. Why is this so important? This small, unheated section creates an isothermal zone9. This is where the machine's thermocouple is placed. It gives the sensor a stable, accurate temperature reading. If the heating coil goes all the way to the end, the temperature reading will constantly bounce around. This causes the PID controller10 to oscillate, and the nozzle temperature can drift by ±5 °C. That much variation is enough to ruin the bond between print layers, making the final part weak and useless.

Critical Design for 3D Printer Heaters

| Feature | Design Rule | Impact of Failure |

|---|---|---|

| Heating Coil Placement | Stop winding 2mm from tip | The PID controller will "hunt" for the setpoint, causing temperature instability. |

| Isothermal Zone | Creates a stable area for the sensor | Poor layer adhesion, weak parts, and potential print failures. |

| Thermocouple Location | Must be in the isothermal zone | Inaccurate temperature readings lead to poor material extrusion quality. |

How Do Cartridge Heaters Work in Semiconductor Equipment?

Are you experiencing equipment failure in high-temperature, inert gas environments? Standard heaters can't handle the extreme conditions. An electrical arc can destroy millions of dollars worth of product.

In semiconductor manufacturing, an Industrial Cartridge Heater needs advanced materials and construction. It must withstand extreme heat and high voltage11 in inert gas. Special alloys and denser insulation are required to prevent catastrophic failure.

This is one of the most demanding applications I have ever worked on. We supply heaters for preheating the base in a wafer epitaxy furnace. These are typically 230V, 800W electric cartridge heaters inserted into a graphite sleeve. The operating environment is brutal: 1000 °C in a pure argon atmosphere. A standard stainless steel heater would disintegrate instantly. For this, the outer shell must be made from Incoloy 800 nickel alloy. But the real challenge is electrical. Argon gas at high temperatures can cause an electrical arc-over. An arc in that furnace would ruin an entire batch of wafers. To prevent this, we had to develop a special manufacturing step for the cold end. We use a "double swaging" process. This compacts the magnesium oxide powder from a normal density of 3.1 g/cm³ up to 3.4 g/cm³. This denser insulation is the only thing that allows the heater to pass the 2000V for 1-second high-potential test required for this job.

Semiconductor Heater Requirements

| Challenge | Solution | Technical Reason |

|---|---|---|

| Extreme Temperature | Incoloy 800 Sheath | This nickel alloy maintains structural integrity and corrosion resistance12 well above 1000 °C. |

| Inert Gas Environment | "Double Swaging" Cold End | Increases MgO density to improve dielectric strength and prevent argon from causing an electrical arc. |

| High Voltage | Pass 2000V, 1s Hipot Test | Guarantees the heater's insulation is robust enough to prevent electrical breakdown during operation. |

Conclusion

To know if a cartridge heater will work, check three things: hole depth, temperature difference, and lead wire temperature13. If the cold end stays cool, it's an incredibly versatile heater.

Learn about the heating methods used in plastic molds to improve production efficiency and product quality. ↩

Explore the causes of thermal shock in heating elements and how to mitigate its effects. ↩

Understand the significance of the transition zone in heating elements and its impact on performance. ↩

Discover how the annealing process improves the durability and reliability of heating elements. ↩

Understand the concept of surface power density and its significance in heater design. ↩

Explore the types of food-grade materials used in heating elements to ensure safety in food applications. ↩

Find out how specialized heaters enhance the performance of 3D printers and improve print quality. ↩

Explore the diverse applications of heating cartridges to understand their importance in various industries. ↩

Learn about the importance of isothermal zones in achieving stable temperature readings in heating applications. ↩

Explore how PID controllers regulate temperature in heating applications for optimal performance. ↩

Understand the challenges associated with high voltage in heating elements and how to address them. ↩

Discover materials that offer corrosion resistance in heating elements for extended service life. ↩

Learn about the impact of lead wire temperature on the overall performance and safety of heating elements. ↩