Are you looking for a versatile and efficient heating solution? Coil heaters might be exactly what you need. They are used everywhere, from industrial machinery to home appliances.

Coil heaters are heating elements shaped into a coil. They convert electrical energy into heat. This heat can then be used for various applications, such as heating liquids, gases, or solids.

I have been in the heating element manufacturing business for over 25 years. I have seen coil heaters evolve significantly. Let’s explore the different types, uses, and how to choose the right one for your needs.

What Are Coil Heaters? Types, Uses, and Safety Tips?

Do you know the different types of coil heaters and their best uses? Understanding this can help you choose the best one for your needs.

Coil heaters come in various forms. These include standard coil heaters, micro coil heaters, and square coil heaters. Each type is designed for specific applications.

Dive Deeper

Let’s break down the types, uses, and safety tips.

First, let’s check the types of coil heaters:

| Type | Description | Common Uses |

|---|---|---|

| Standard Coil Heaters | These are typically larger and used for general heating purposes. | Industrial heating, plastic molding, and large-scale applications. |

| Micro Coil Heaters | Smaller in size. They are for precision heating in tight spaces. | Hot runner systems, medical devices, and applications needing precise heat. |

| Square Coil Heaters | These have a square cross-section. They provide uniform heating over a surface. | Sealing, packaging, and applications requiring flat surface contact. |

Next, let’s look at how these heaters are used:

| Application | Description | Why Coil Heaters Are Ideal |

|---|---|---|

| Plastic Molding | Heating molds to maintain the right temperature for plastic injection. | Provide consistent and even heat, which is important for quality plastic products. |

| Hot Runner Systems | Maintaining the temperature of molten plastic in injection molding systems. | Micro coil heaters offer precise temperature control in tight spaces. |

| Semiconductor Industry | Heating wafers and other components during manufacturing processes. | Accurate temperature control is vital for producing high-quality semiconductors. |

| Packaging | Sealing and bonding materials together using heat. | Square coil heaters provide uniform heat for effective sealing. |

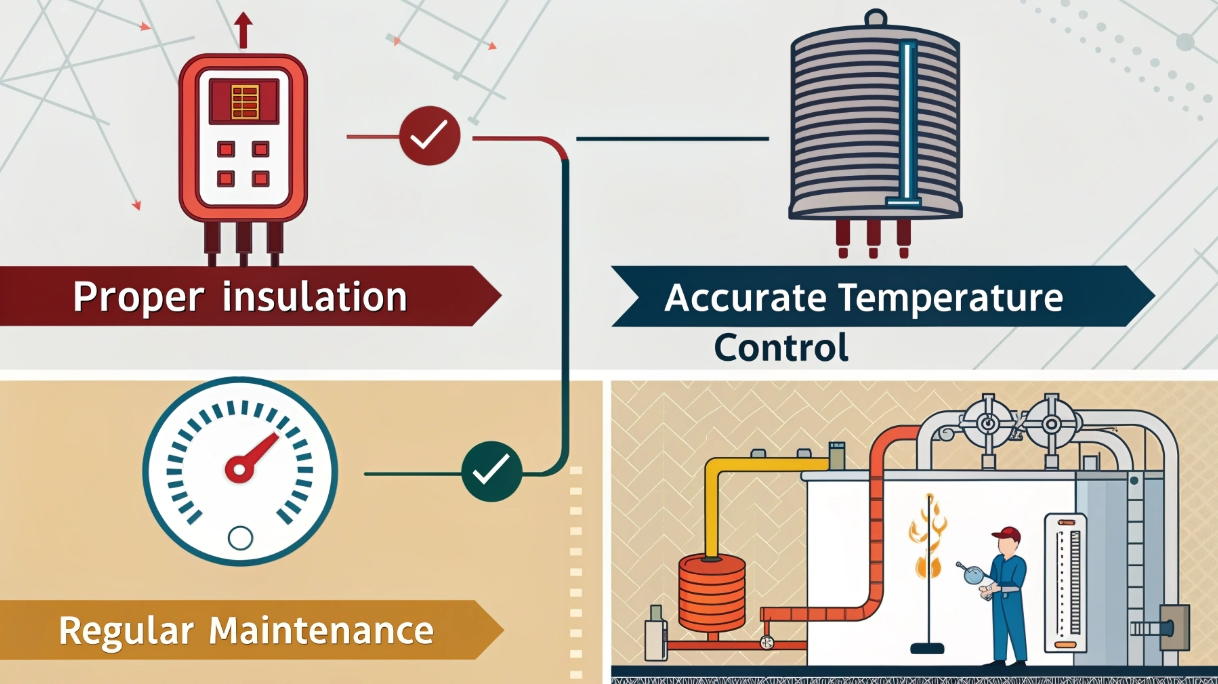

Finally, here are some safety tips:

| Safety Tip | Description | Importance |

|---|---|---|

| Proper Insulation | Make sure the heater is properly insulated to prevent heat loss and burns. | Improves energy efficiency and reduces the risk of accidents. |

| Temperature Control | Use a temperature controller to avoid overheating. | Prevents damage to the heater and the materials being heated. |

| Regular Maintenance | Inspect the heater regularly for wear and damage. | Helps identify and fix problems early, extending the life of the heater. |

| Grounding | Make sure the heater is properly grounded. | Prevents electric shock. |

Industrial vs. Home Use: Choosing the Right Coil Heater?

Do you know which coil heater is best for industrial or home use? The right choice depends on your specific requirements.

Industrial coil heaters are for heavy-duty applications. They need to provide high heat output and durability. Home-use coil heaters are smaller and for lighter tasks. They focus on safety and energy efficiency.

Dive Deeper

When choosing a coil heater, consider the following:

- Heating Requirements: How much heat do you need?

- Size and Space: How much space do you have for the heater?

- Safety Features: What safety features are needed for your application?

Let’s compare industrial and home-use coil heaters in detail:

| Feature | Industrial Coil Heaters | Home-Use Coil Heaters |

|---|---|---|

| Material | High-grade stainless steel, Inconel | Stainless steel, ceramic |

| Temperature Range | Up to 1200°C | Up to 300°C |

| Power Output | High (several kilowatts) | Low to medium (hundreds of watts) |

| Durability | Designed for continuous operation in harsh conditions | Designed for intermittent use |

| Safety Features | Overheat protection, robust insulation | Overheat protection, child safety features |

| Common Applications | Plastic injection molding, die casting, industrial ovens | Water heaters, electric stoves, space heaters |

For industrial applications, coil heaters need to withstand high temperatures and continuous use. For home use, safety and energy efficiency are the most important. My company, ELEKHEAT, makes industrial coil heaters with materials like Inconel. They can handle very high temperatures and last a long time, even with constant use.

Maximizing Efficiency: How to Optimize Electric Coil Heater Performance?

Do you want to get the most out of your electric coil heater? Proper optimization can save energy and extend the heater’s lifespan.

To optimize coil heater performance, make sure of proper insulation, accurate temperature control, and regular maintenance. Good insulation reduces heat loss. Accurate control prevents overheating. Regular maintenance identifies and fixes potential problems.

Dive Deeper

Here are some ways to improve coil heater performance:

| Optimization Method | Description | Benefits |

|---|---|---|

| Insulation | Use high-quality insulation materials around the heater to minimize heat loss. | Reduces energy consumption, maintains consistent temperature, and improves heater efficiency. |

| Temperature Control | Use a PID (Proportional-Integral-Derivative) temperature controller for accurate temperature management. | Prevents overheating, maintains consistent temperature, extends heater lifespan, and improves process control. |

| Regular Maintenance | Check the heater and its connections regularly. Look for signs of wear or damage. | Identifies and fixes problems early, prevents costly repairs, and extends heater lifespan. |

| Proper Wiring | Use the correct gauge wiring and make sure of secure connections to minimize resistance. | Improves energy efficiency, prevents electrical hazards, and ensures consistent heater performance. |

| Load Matching | Make sure the heater is correctly sized for the application to avoid under or over heating. | Optimizes energy use and prevents heater burnout. |

For example, one of our clients in the food processing industry was having problems with their heating system. They were losing a lot of heat. By adding better insulation and using PID temperature controllers, they reduced their energy consumption by 20%. This also extended the life of their heaters.

DIY Coil Heater Projects: A Step-by-Step Guide for Beginners?

Are you interested in building your own coil heater for a small project? With the right guidance, it’s a fun and educational experience.

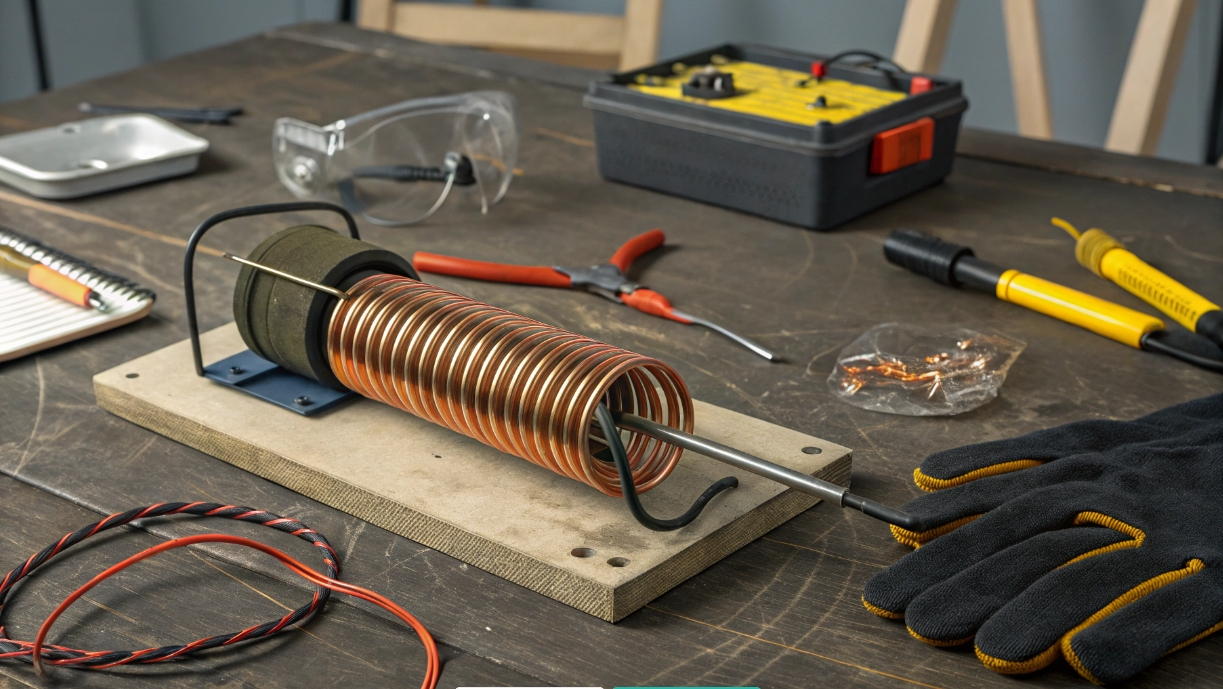

Building a DIY coil heater involves winding resistance wire around a core, insulating it, and connecting it to a power source. It’s very important to follow safety precautions to prevent electric shock and burns.

Dive Deeper

Here’s a simple step-by-step guide:

| Step | Description | Materials Needed |

|---|---|---|

| 1 | Gather your materials. You will need resistance wire, a ceramic or metal core, insulation, and connecting wires. | Resistance wire (e.g., nichrome), ceramic or metal core, high-temperature insulation tape, connecting wires. |

| 2 | Wind the resistance wire tightly and evenly around the core. | Pliers, gloves |

| 3 | Insulate the coil with high-temperature insulation tape. | High-temperature insulation tape |

| 4 | Connect the connecting wires to the ends of the resistance wire. | Soldering iron, solder, wire strippers |

| 5 | Test the heater with a low-voltage power source. | Low-voltage power supply, multimeter |

Safety First: Always wear gloves and eye protection. Work in a well-ventilated area. Make sure the power source is disconnected before working on the heater.

I once helped my son build a small coil heater for a school project. We used a ceramic core and nichrome wire. It was a great way to teach him about electricity and heat. He learned a lot about the importance of safety when working with electrical components.

Industrial Coil Heaters 101: Materials, Temperatures, and Custom Solutions?

Do you need a coil heater for a specific industrial application? Knowing the right materials, temperatures, and customization options is vital.

Industrial coil heaters must withstand high temperatures, harsh chemicals, and continuous use. Common materials include stainless steel, Inconel, and ceramic. Custom solutions can be designed to meet specific heating needs.

Dive Deeper

Let’s dive into the key aspects of industrial coil heaters:

| Aspect | Description | Material Examples | Temperature Range |

|---|---|---|---|

| Materials | The materials used must be durable and resistant to high temperatures and chemicals. | Stainless Steel, Inconel, Ceramic, Quartz | Varies by material |

| Temperature | Different applications need different temperature ranges. The heater must be able to maintain the required temperature. | N/A | Up to 1200°C |

| Customization | Custom solutions can be designed to meet specific heating needs. | Custom shapes, sizes, wattage, voltage, and connections | N/A |

| Applications | Coil heaters are used in a wide range of industrial applications. | Plastic Molding, Die Casting, Industrial Ovens | Varies by application |

Customization is a big part of what we do at ELEKHEAT. We work with our clients to design coil heaters that meet their exact needs. For example, we created a custom coil heater for a client in the aerospace industry. It needed to heat a specific component to a very precise temperature. We used Inconel for its high-temperature resistance and designed a unique shape to fit the component perfectly.

Conclusion

Coil heaters offer a versatile and efficient heating solution for many applications. By understanding the types, uses, and optimization methods, you can choose the right heater for your needs and maximize its performance.