The Professional's Guide to Industrial Flange Heaters

The essential knowledge for engineers, technicians, and purchasing professionals to specify, install, and maintain these vital components.

In This Guide:

- What is a Flange Heater?

- How They Work: Anatomy and Principle

- Materials & Configurations

- Key Industrial Applications

- Core Benefits of Flange Heaters

- How to Select the Right Flange Heater

- Interactive Selection Helper

- Installation & Maintenance

- Frequently Asked Questions (FAQs)

- Conclusion & Next Steps

1. What is a Flange Heater?

A flange heater is a high-capacity electric immersion heater. It consists of hairpin-bent tubular heating elements welded or brazed into a standard ANSI flange. This assembly is bolted directly onto a tank or vessel, immersing the elements in the fluid for fast and efficient heating. For a broader overview of this technology, see our complete immersion heater guide.

They are the workhorses of industrial electric heaters, critical for processes in oil and gas, chemical processing, and food production where precise and reliable heating is non-negotiable.

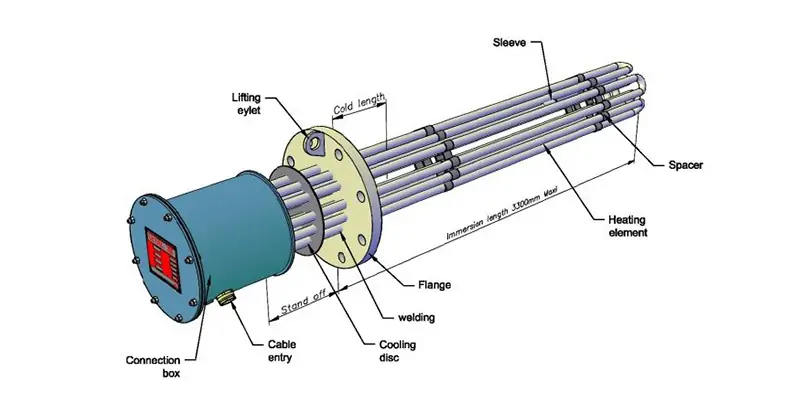

2. How They Work: Anatomy and Principle

The effectiveness of a flange heater lies in its simple design and direct heating method.

Key Components

- Heating Elements: A bundle of tubular rods containing a high-resistance wire that generates heat. This wire is insulated from the outer protective sheath by compacted Magnesium Oxide (MgO), which ensures excellent heat transfer and electrical insulation.

- The Flange: A standardized plate (e.g., ANSI B16.5) that provides a secure, high-pressure mounting point on the vessel.

- Terminal Enclosure: A protective housing for the electrical connections, rated (e.g., NEMA 4, NEMA 7) to withstand environmental conditions like moisture or explosive atmospheres.

The Principle: Direct Immersion Heating

Flange heaters work by passing an electric current through the resistance wire, generating heat. Because the elements are directly immersed in the fluid, this heat is transferred with nearly 100% efficiency, resulting in rapid heating and minimal energy loss.

3. Materials & Configurations

Proper material selection is the single most important factor for heater longevity.

Element Sheath Material Selection

| Fluid Type | Recommended Sheath | Max Temp (°C) | Notes |

|---|---|---|---|

| Water | Copper, Incoloy | 140 | Low scaling risk |

| Oil | Incoloy 800, Steel | 300–400 | Ensure proper thermal control to prevent coking |

| Caustic Soda | Titanium, Inconel | ≤120 | Needs highly corrosion-resistant metal |

Key Specifications

- Watt Density (W/sq.in.): The most critical spec. It's the heat output per square inch of the element surface. Too high, and you'll scorch the fluid or burn out the heater. Too low, and the heater will be inefficient.

- Flange Size & Rating: Must match the vessel's nozzle and pressure requirements (e.g., 6-inch, 150 lb ANSI). An ASME flange heater is required for high-pressure vessels under the ASME code.

- Voltage & Power: Configured for standard industrial voltages (240V, 480V) and power ratings from a few kilowatts to over a megawatt.

How to Choose Flange and Terminal Housing

The flange material itself is typically carbon steel for general applications or stainless steel for corrosive media or sanitary requirements. The terminal housing is equally critical and must be chosen based on the operating environment. The table below outlines the common NEMA enclosure types.

| NEMA Rating | Protection Against | Common Applications |

|---|---|---|

| NEMA 1 | Falling dirt, accidental contact | General-purpose indoor, clean, dry locations |

| NEMA 4/4X | Hose-directed water, dust, rain, snow. 4X adds corrosion resistance. | Outdoor use, washdown areas, food processing, marine environments |

| NEMA 7 | Internal explosions of specified flammable gases/vapors | Hazardous locations (Class I, e.g., refineries, chemical plants) |

| NEMA 9 | Combustible dust | Hazardous locations (Class II, e.g., grain elevators, coal plants) |

4. Key Industrial Applications

Flange mounted heaters are vital across numerous sectors. While they heat fluids within a tank, for applications requiring heating of flowing liquids outside a primary vessel, a circulation heater may be more appropriate.

- Oil & Gas: Heating crude oil to reduce viscosity for transport and preventing hydrate formation in gas pipelines.

- Chemical Processing: Providing precise temperature for reactors and heating corrosive solutions.

- Food & Beverage: Sterilizing equipment with Clean-in-Place (CIP) systems and pasteurizing liquids.

- Water Treatment & Boilers: Acting as the primary heat source in industrial boilers and large hot water tanks.

- Power Generation: Superheating steam to drive turbines more efficiently.

5. Core Benefits of Flange Heaters

- High Efficiency: Direct immersion provides nearly 100% energy efficiency, reducing operating costs.

- Precise Control: Easily integrated with thermocouples and digital controllers for exact temperature regulation.

- Easy Maintenance: The entire unit can be unbolted and removed for service or replacement, minimizing downtime.

- Robust & Safe: Designed for high-pressure use and available with explosion-proof enclosures for hazardous locations.

6. How to Select the Right Flange Heater: A 4-Step Guide

- Analyze the Fluid: Determine the fluid's viscosity, corrosiveness, and potential for contamination. This dictates the required sheath material.

- Determine the Watt Density: Based on the fluid type, select a watt density that will not cause damage. For example, for heating water at 60°C, the recommended watt density is around 50 W/sq.in. A 6" flange heater rated at 12 kW with 6 elements would result in approximately 48 W/sq.in. — suitable for water heating. Using an online watt density calculator for heaters can help with precise calculations.

- Calculate Heat Requirements: Determine the necessary kilowatt (kW) rating based on the volume of fluid, required temperature rise, and desired heat-up time.

- Specify Mechanical & Electrical Needs: Match the flange size and pressure rating to the vessel. Ensure the voltage is compatible with the power supply and select the correct NEMA rating for the terminal enclosure. Always demand certifications like UL, CSA, or ASME where required.

Safety, Compliance, and Enclosures

Flange heaters must comply with standards like UL 499 and CSA C22.2 No. 72. For European markets or hazardous locations, ATEX certification may be required. The choice of terminal housing is critical for safety. A NEMA 4X enclosure for immersion heaters is ideal for corrosive or washdown environments, while a NEMA 7 enclosure is necessary for explosion-proof applications. Furthermore, ensure the ANSI B16.5 flange ratings (e.g., Class 150, 300) match your vessel's pressure and temperature limits.

7. Interactive Selection Helper

Use this form to get instant recommendations for your application based on the principles discussed in this guide.

Your Recommended Configuration:

This tool is for reference only, please select according to the actual situation.

8. Installation & Maintenance

Pre-Installation & Wiring Checklist

- Inspect Gasket and Flange Surfaces: Ensure both surfaces are clean, dry, and free of defects before installation.

- Torque Bolts Correctly: Tighten flange bolts in a star pattern to the manufacturer's specified torque to ensure an even, leak-proof seal.

- Verify Ground Connection: Confirm that the heater is securely and properly grounded according to electrical codes.

- Check Controls: Ensure the thermostat and high-limit controls are properly set and protected from the environment.

- Perform a Megohm Test: Before energizing, check the heater for moisture contamination to prevent a short circuit.

Maintenance Schedule

| Maintenance Task | Frequency |

|---|---|

| Inspect for scale/corrosion | Monthly |

| Verify thermostat function | Quarterly |

| Check terminal tightness | Quarterly |

| Full cleaning/flush | Annually |

9. Frequently Asked Questions (FAQs)

Q: What is the difference between a flange heater and a screw plug heater?

A: The main difference in the flanged vs threaded heater debate is mounting and power capacity. Flange heaters are high-power units bolted onto large tanks via an ANSI flange. Screw plug heaters are smaller, lower-power units that screw into a threaded opening (NPT), making them ideal for smaller tanks.

Q: How do I calculate the correct watt density?

A: Watt density is calculated by dividing the heater's total wattage by the heated surface area of the elements (in square inches). While a watt density calculator for heaters can provide precise figures, a good starting point is to use a reference chart that matches your fluid type to a recommended watt density range to prevent fluid degradation or heater failure.

Q: What maintenance is required for flange heaters?

A: Regular maintenance includes monthly visual inspections for scale or corrosion, quarterly checks of the thermostat and terminal tightness, and a full cleaning or flush annually. This ensures optimal performance and longevity.

Q: Are flange heaters safe for hazardous areas?

A: Yes, when specified correctly. An explosion-proof flange heater is designed with a NEMA 7 or NEMA 9 enclosure and must be certified (e.g., ATEX, CSA) for the specific Class, Division, and Group of the hazardous environment.

10. Conclusion & Next Steps

Choosing the right flange heater is a critical engineering decision. By focusing on the fluid properties, correct watt density, and proper material selection, you can ensure a safe, efficient, and long-lasting heating solution.

Ready to Specify Your Heater?

Our experts are here to help you select the perfect heating solution for your application.

Latest Posts

If you have any needs, please contact us