Industrial heating in volatile environments is dangerous. A single spark can lead to catastrophic explosions and plant shutdowns. Secure your facility with explosion-proof flange heaters designed to contain risks and provide reliable heat.

An explosion-proof flange heater is a heavy-duty immersion device that heats liquids or gases in hazardous areas. It uses a flame-proof enclosure to trap internal sparks. These heaters are essential for heating oil, alcohol, or chemicals where flammable vapors are present, ensuring maximum safety through thermal control.

Understanding how these heaters work is the first step toward a safer factory.

How does an explosion-proof flange heater actually work?

Heating flammable fluids is risky because a simple electrical arc can trigger a fire. You need a design that separates the heat source and the spark source from the explosive atmosphere.

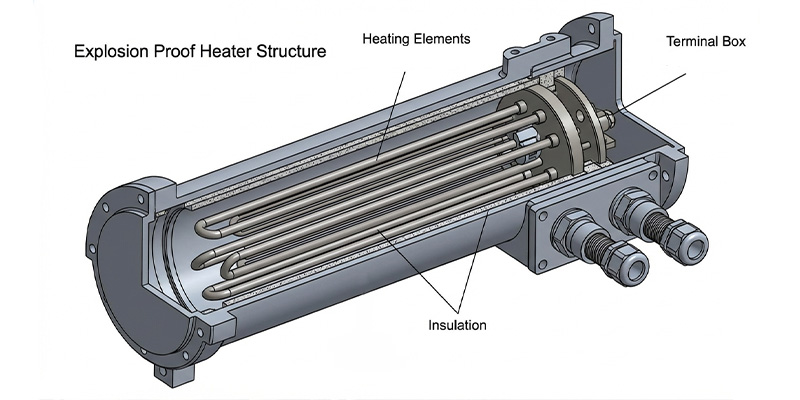

An explosion-proof flange heater works by encasing resistance wires in insulated metal tubes. It uses a bolted, flame-path enclosure to contain any internal electrical failures. This prevents internal flames from reaching the outside gas, ensuring your "bath" of oil or gas stays safe.

The Internal Heating Core

Inside each tube is a coiled resistance wire. This wire generates heat when electricity passes through it. We fill the space between the wire and the tube wall with high-purity Magnesium Oxide (MgO) powder. This powder is a "thermal bridge." It conducts heat to the outer sheath but blocks electricity. At ELEKHEAT, we ensure the MgO is packed tightly to prevent air gaps that cause premature failure.

The "Mini-Safe" Enclosure

The junction box is the most critical part. Think of it as a mini-safe. The metal walls are thickened. The threads and joints are machined to extremely tight tolerances. If a spark occurs inside the box, the flame cannot squeeze through the tiny gaps. By the time the hot gas reaches the outside, it has cooled down enough that it cannot ignite the surrounding atmosphere.

Dual-Layer Temperature Monitoring

We don't just rely on the metal structure. We integrate temperature and liquid level sensors directly into the heater bundle. If the liquid level drops or the temperature spikes, the system cuts power in less than a second. This prevent "dry firing," which is the leading cause of heater sheath melting.

| Component | Material/Function | Safety Benefit |

|---|---|---|

| Heating Elements | Stainless Steel/Incoloy | High pressure and corrosion resistance |

| MgO Powder | High-purity grade | Electrical insulation and fast heat transfer |

| Explosion-proof Box | Carbon Steel or SS304/316 | Contains internal sparks and explosions |

| Thermocouple | Type K or J | Provides real-time over-temperature protection |

| Flange | ANSI or DIN Standard | Provides a leak-proof seal for high-pressure tanks |

How do you choose the right material and specifications?

Picking the wrong heater is a costly mistake. If the material does not match the fluid, the heater will corrode and leak within months.

To choose correctly, you must match the sheath material to the chemical properties of your fluid. For example, use Stainless Steel 316L for mildly corrosive liquids and Titanium for high-salt environments. Never prioritize a lower price over material compatibility, as downtime costs more than the heater itself.

Identifying the Heating Medium

In our 25 years of experience, we have seen many buyers choose standard 304 Stainless Steel for everything. This is a mistake. If you are heating treated water, 304 is fine. However, if you are heating crude oil or acidic solutions, you need Incoloy or specialized coatings. At ELEKHEAT, we analyze the pH level of your fluid before recommending a material.

Understanding Hazardous Zone Ratings

You must know your "Zone." Different industries have different rules.

- Zone 1: High risk, requires Ex d IIC T4 or higher.

- Zone 2: Lower risk, but still requires certified explosion-proof housing. Don't try to save a few hundred dollars by buying a "general purpose" heater for a chemical plant. The fines from safety inspectors alone will cost more than a high-end heater. Always look for ATEX, IECEx, or local equivalent certifications.

Calculating Power Density (Watt Density)

Watt density is how much heat comes out of every square inch of the heater tube. If the density is too high for the fluid (like oil), the fluid will "carbonize" or burn onto the tube. This creates a crust that traps heat and burns out the heater. For heavy oils, we recommend low watt densities (around 10-15 Watts per square inch).

| Application | Recommended Sheath Material | Typical Watt Density (W/in²) |

|---|---|---|

| Clean Water | Stainless Steel 304 | 50 - 75 |

| Deionized Water | Stainless Steel 316L | 40 - 60 |

| Lubricating Oil | Carbon Steel / SS304 | 15 - 20 |

| Corrosive Acids | Titanium / Teflon Coating | 10 - 25 |

| Air / Gas Heating | Incoloy 800 | 15 - 30 |

What maintenance steps ensure long-term safety?

Even the best explosion-proof heater needs care. Neglect leads to insulation breakdown, which is the primary cause of electrical shorts.

Effective maintenance requires monthly terminal inspections and annual insulation resistance tests. If the insulation value drops below 50 MΩ, the heater must be dried or replaced immediately. Preventing dry-burning by maintaining proper liquid levels is the most important factor in extending the life of your equipment.

Monthly Terminal Checks

Every month, your technicians should open the explosion-proof box (after cutting power). Check for loose wires. Loose connections create heat and can melt the terminal block. If the box feels unusually hot during operation, it may indicate that the MgO powder inside the rods is degrading and causing a heat bottleneck.

The 200 MΩ Insulation Rule

Every year, use a megohmmeter (insulation tester) to "shake" the heater. Set it to 500V or 1000V. Ideally, you want a reading above 200 MΩ. If the reading drops below 50 MΩ, moisture has likely entered the tube. We often tell our clients to bake the heater in an industrial oven to drive out the moisture before it causes a short circuit.

Monitoring the Liquid Level

The heater must always be submerged. If the liquid level drops and the rods are exposed to air, the temperature will soar to over 1000°F in minutes. Even the strongest explosion-proof housing cannot stop a tube from melting and leaking high-voltage electricity into your tank. Always interlock your heater with a reliable level switch.

| Maintenance Task | Frequency | Action Required |

|---|---|---|

| Visual Inspection | Weekly | Check for leaks around the flange bolts. |

| Terminal Check | Monthly | Tighten screws and look for signs of overheating. |

| Insulation Test | Yearly | Ensure resistance is > 50 MΩ using a megger. |

| Scale Removal | Every 6 Months | Clean the tubes to prevent hotspots and corrosion. |

Conclusion

Explosion-proof flange heaters are the "security guards" of your industrial heating system. They provide safe, efficient heat while protecting your facility from fire and explosions.

At ELEKHEAT, we specialize in custom-built heating solutions tailored to your specific chemical environment. Whether you need specialized materials or high-wattage configurations, we ensure your plant stays warm and safe. Contact us today for a technical consultation.