How Do You Choose the Right Heating Element Supplier?

Choosing the wrong supplier leads to costly downtime and failures. Your production line stops, and profits suffer. Partner with an expert supplier like Elekheat to ensure reliability and performance.

A reliable heating element supplier provides custom solutions, quality materials, and expert engineering support. They ensure your equipment runs efficiently and prevents costly failures, focusing on long-term value over initial price.

The choice of a supplier is more than just a purchase. It's a critical decision that affects your product's quality and your company's bottom line. But with so many options, how do you know what to look for? We need to look beyond the catalog and understand the core technology. Let's break down what really matters, starting with the hardware itself.

Article Directory

What Type of Heater Does Your Project Actually Need?

You picked a heater, but it's inefficient for the job. Now, your energy bills are high and performance is poor. You need to understand the basic types to make a smart choice.

Choosing the right heater depends on your application. Immersion heaters are for liquids, cartridge heaters are for precise metal heating, and flexible heaters are for complex shapes. Matching the heater to the job is key.

Finding the right heating element supplier starts with knowing what you need. There is no one-size-fits-all solution. The best heater is the one designed for your specific task. It works by converting electricity to heat, but *how* it transfers that heat is what defines its type and best use. At Elekheat, we help you navigate these choices every day. Here’s a simple breakdown of the main categories to get you started.

Heating from Within: Immersion Heaters

These are for heating liquids directly. Think of heating water, oils, or chemical solutions in a tank. Because the heater is submerged, it's very efficient. We make several kinds, like flanged heaters with multiple elements for big tanks, screw plug heaters for smaller containers, and versatile over-the-side heaters for open vats.

Precision and Power: Conduction Heaters

These heaters transfer heat through direct contact. A cartridge heater, for example, is a small, powerful cylinder that you insert into a hole in a metal block, like a mold or die. It provides fast, precise heat. Strip heaters are flat and get bolted to a surface, while band heaters wrap around a pipe or barrel. The most versatile is the tubular heater, which can be bent into almost any shape for air or liquid heating.

Conforming to Complexity: Flexible Heaters

What if the surface you need to heat is curved or has a weird shape? That's where flexible heaters come in. Made from materials like silicone rubber or Kapton®, these thin heaters can be wrapped around or bonded to almost any surface. They are perfect for medical devices, electronics, and aerospace parts where space and weight are critical.

| Heater Type | Primary Use | Best For |

|---|---|---|

| Immersion Heaters | Heating liquids in tanks | Water, oils, chemical solutions |

| Cartridge Heaters | Precise heating of metal parts | Molds, dies, platens |

| Flexible Heaters | Heating complex or curved surfaces | Medical devices, electronics |

| Tubular Heaters | Versatile heating for air and liquids | Ovens, ducts, large tanks |

Why Do Materials Matter So Much in a Heating Element?

Your heating elements fail too quickly. Constant replacements are eating into your budget and time. The problem might be the materials used in the element.

The right materials determine a heater's lifespan and performance. Key alloys like Nichrome and FeCrAl handle different temperatures, while the outer sheath protects against corrosion. Quality materials prevent premature failure.

A heating element is only as good as the materials it's made from. A low price can be tempting, but if it means low-quality materials, you will pay more in the long run through failures and downtime. As a heating element supplier since 1997, we've seen firsthand how crucial material selection is. It's the foundation of a reliable product.

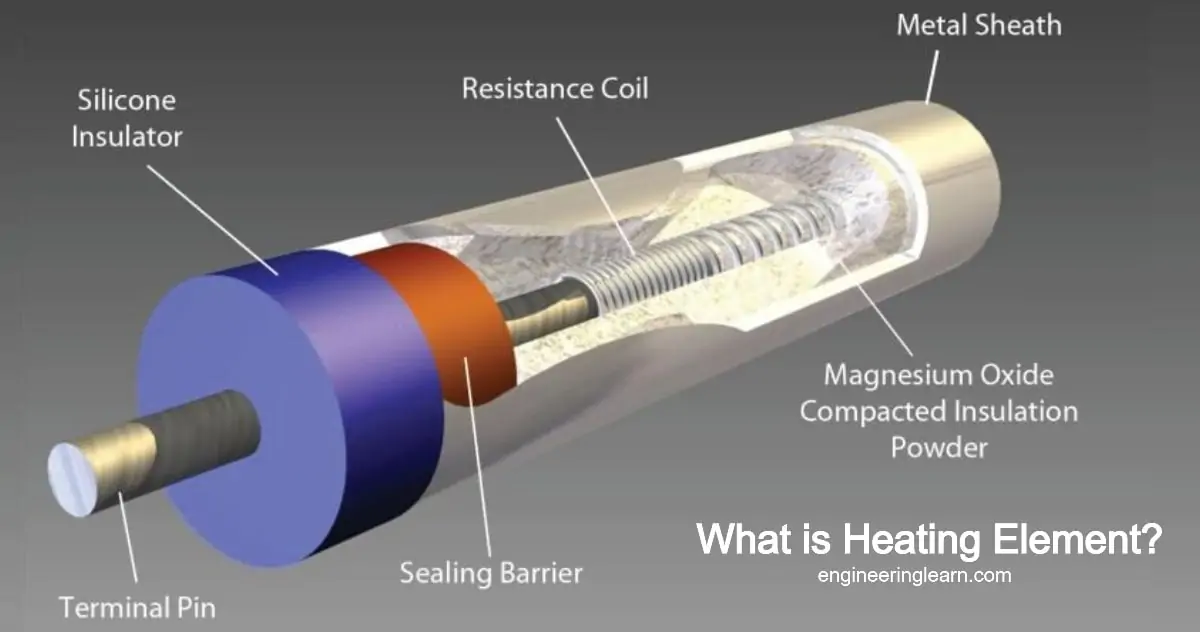

The Heart of the Heater: Resistance Wire

The wire inside the heater is what actually generates the heat. The two most common materials are Nickel-Chromium (Nichrome) and Iron-Chromium-Aluminum (FeCrAl). Nichrome is a great all-around choice for many applications up to 1200°C. When first heated, it forms a protective layer of chromium oxide that prevents it from burning out. FeCrAl can handle much higher temperatures (up to 1400°C) and is better in sulfurous environments, making it ideal for industrial furnaces.

The Armor: Sheath Materials

The outer tube, or sheath, protects the internal wire. This is the element's first line of defense. If you're heating a corrosive chemical, you need a sheath that can resist it. We use different materials like stainless steel for general use, Incoloy® for high temperatures, and even titanium for very specific corrosive solutions. The wrong sheath will lead to a quick failure, no matter how good the wire inside is.

The Unsung Hero: Insulation

Inside a tubular or cartridge heater, there's a special powder separating the wire from the sheath. This is usually high-purity Magnesium Oxide (MgO). It's a fantastic electrical insulator, so the current stays in the wire. But it's also a great thermal conductor, so it efficiently moves the heat from the wire to the outside sheath. Using low-quality or impure MgO can cause the heater to short out and fail.

| Material | Max Temperature | Best For |

|---|---|---|

| Nickel-Chromium (NiCr) | High (up to ~1200°C) | General purpose, good durability |

| Iron-Chromium-Aluminum (FeCrAl) | Very High (up to ~1400°C) | Industrial furnaces, high-temp processes |

| Stainless Steel Sheath | Varies by grade | General use, moisture resistance |

| Incoloy® Sheath | Very High | High-temperature and corrosive environments |

Beyond the Price Tag: What's the True Cost?

You chose the cheapest heater to save money. But now you're facing constant failures and expensive downtime. The hidden costs are hurting your bottom line.

The true cost of a heater is its Total Cost of Ownership (TCO). This includes the initial price plus energy, maintenance, and downtime costs. A quality heater saves you money in the long run.

The Total Cost of Ownership (TCO) Formula

A common mistake is choosing a heater based only on its initial price. The cheapest heater is almost never the most cost-effective. A better way to look at it is the Total Cost of Ownership, or TCO. A quality heater might cost more upfront, but it saves you money over its life by being more energy-efficient, lasting longer, and preventing expensive production shutdowns.

Think about a plastic injection molding line. A cheap cartridge heater fails and stops production. The cost of that lost output and wasted material can be thousands of dollars. Suddenly, the slightly more expensive, high-reliability heater looks like a bargain. To avoid this trap, you need a simple plan.

Step 1: Define Your Needs

First, be very clear about what you need. What are you heating (water, oil, air, metal)? What is your target temperature? What is the environment like (corrosive, high-vibration)? Answering these questions is the first step to getting the right heater.

Step 2: Calculate Your Power

Next, you need to figure out how much power, or wattage, you need. This depends on the mass of what you're heating, the temperature change you need, and how fast you need to heat it. Don't forget to account for heat loss to the environment. We can help you with these calculations to make sure your heater isn't undersized.

Step 3: Check the Fit

Finally, consider the physical space. Will the heater fit? How will it be installed? How will you connect the wires? Thinking about these practical details early on will save you major headaches later.

What Separates a Great Supplier from Just a Good One?

Your current supplier just sells parts from a catalog. You're left alone to solve complex heating problems. You need a partner who offers real engineering support and expertise.

A great heating element supplier is an engineering partner. They offer custom designs, expert advice, and certifications like ISO 9001 and UL. This ensures quality, safety, and a solution that truly fits your needs.

I remember a client from the food processing industry who came to us. They were using a standard heater from another supplier, and it kept failing, contaminating their product. They were frustrated. Instead of just selling them another standard part, we sat down with them. We looked at their process, the temperatures, and the cleaning agents they used.

We ended up designing a fully custom tubular heater with a specific stainless steel sheath that could withstand their cleaning process. It cost a bit more upfront, but it solved their problem for good. That's the difference. A great supplier doesn't just take your order; they solve your problem.

Customization and Engineering Support

Your application is unique. A great supplier has an engineering team that can design a custom heater just for you. They ask the right questions to understand your challenge and become an extension of your own team.

Proof of Quality: ISO and UL Certifications

Certifications aren't just logos. They are proof of quality and safety. ISO 9001 means the supplier has a rock-solid quality system. You get a consistent, reliable product every time. UL Recognition means the heater has been tested for safety. Using UL Recognized parts makes it much easier and safer to get your final product certified. At Elekheat, we are proud to hold these certifications. It's our promise of quality to you.

Supply Chain Resilience

In today's world, where parts come from matters. A great supplier has a strong supply chain. At Elekheat, we focus on domestic manufacturing and keeping a large inventory of raw materials. This means we have more control over quality and can deliver parts faster, protecting you from international shipping delays and disruptions.

Your Partner for Thermal Success

Choosing the right supplier is a strategic decision. It's about finding a partner who understands your challenges and delivers reliable, custom solutions that provide the best long-term value.