Efficient, Application‑Tuned Heating for water, Oils & Process Fluids

Flange, screw‑plug and side‑mount designs with engineered watt density, robust materials and hazardous‑location options.

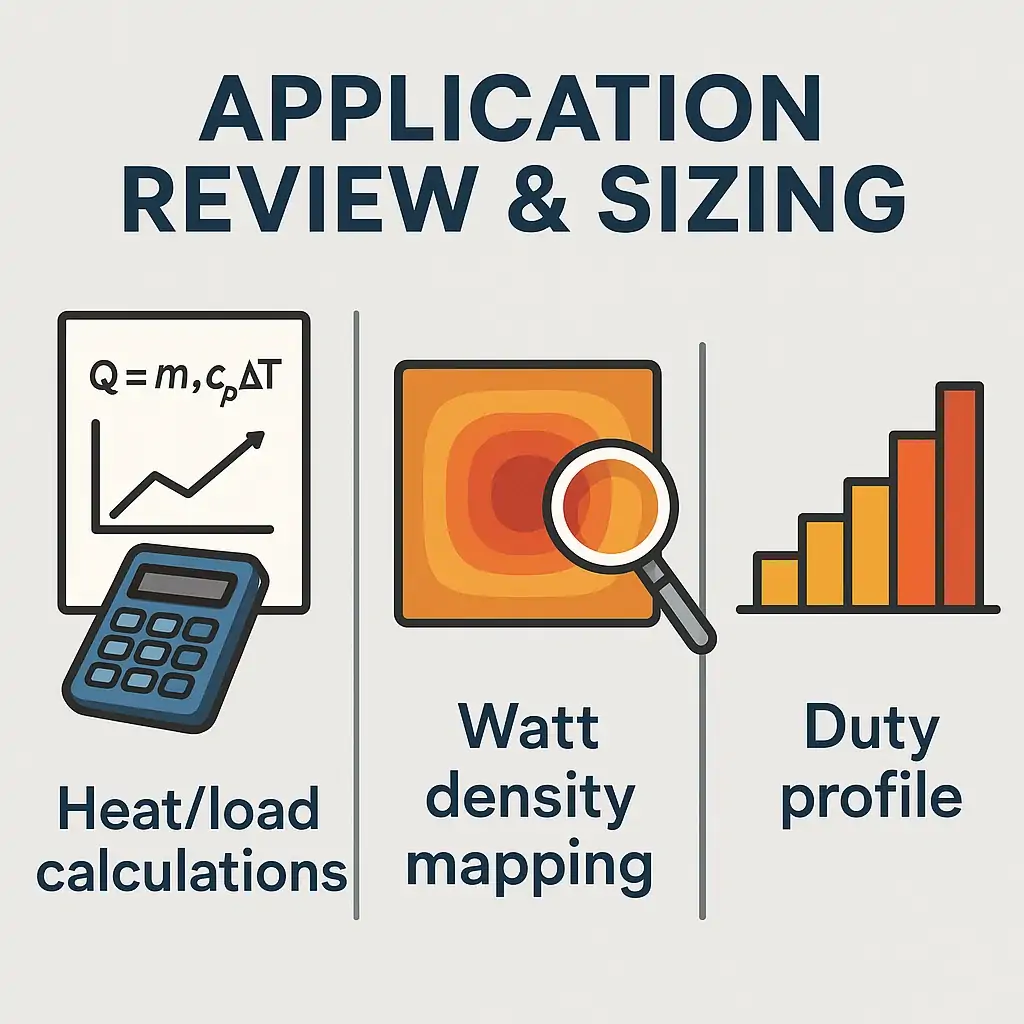

Process‑driven sizing

Watt density matched to your fluid

Hazardous‑location options

ATEX/IECEx/NEC

Traceable materials

MTR & FAT reports

Product Categories

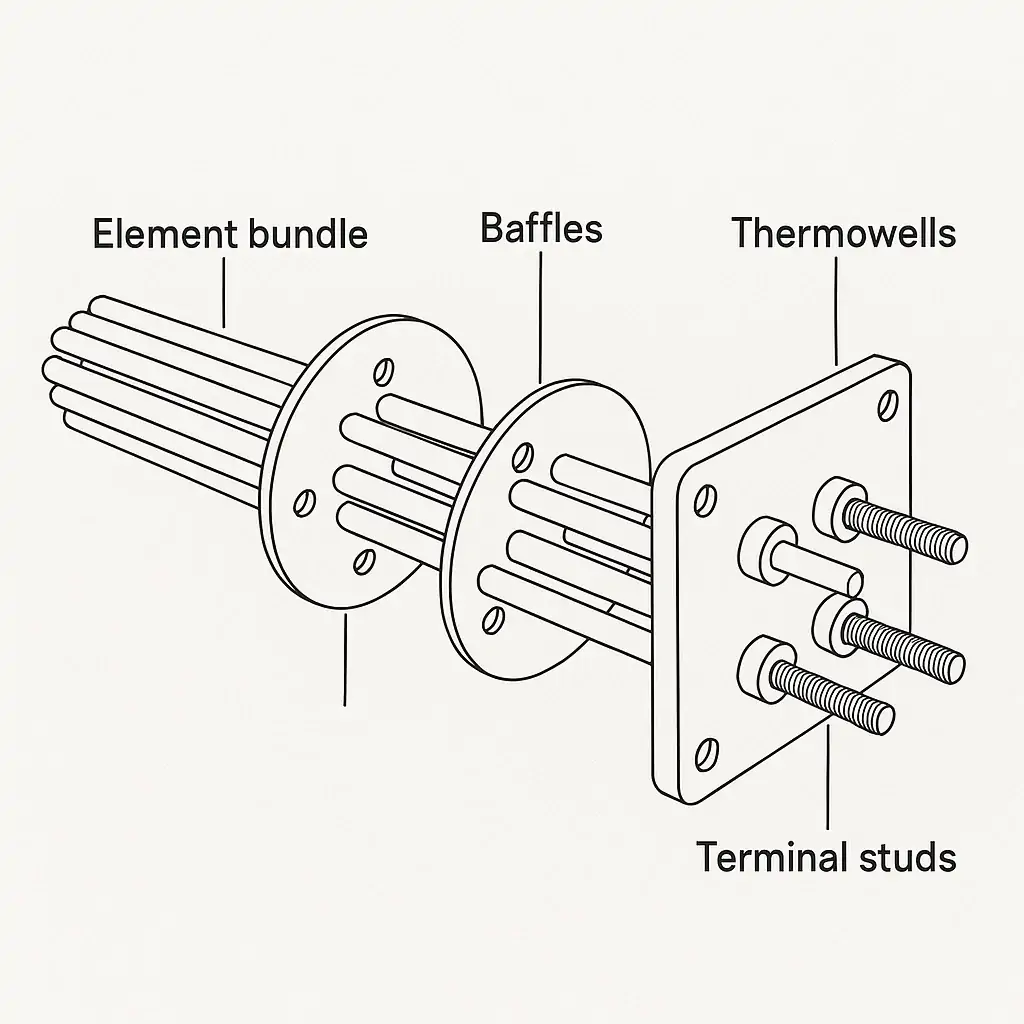

High‑power, pressure‑rated bundles for tanks and vessels.

30–1,500 kW · ASME B16.5 · Replaceable elements · EX options

Compact heaters for small/medium tanks with integral control options.

0.5–120 kW · 1″–3″ NPT/BSP · NEMA/IP enclosures

External‑access solutions for retrofits and easy maintenance.

5–300 kW · Removable bundles · Insulation kits

Hygienic, scale‑aware designs for water and aqueous media.

316L/copper · 10–20 W/cm² · Anodes optional

Compact heaters for small/medium tanks with integral control options.

0.5–120 kW · 1″–3″ NPT/BSP · NEMA/IP enclosures

Why choose ELEKHEAT immersion heaters?

- Process‑driven sizing — heat‑up, hold and losses calculated; watt density tuned to fluid.

- Hazardous‑location designs — EX d/e terminal boxes, certified assemblies.

- Energy efficiency — high immersion efficiency, SCR/PID control, insulation options.

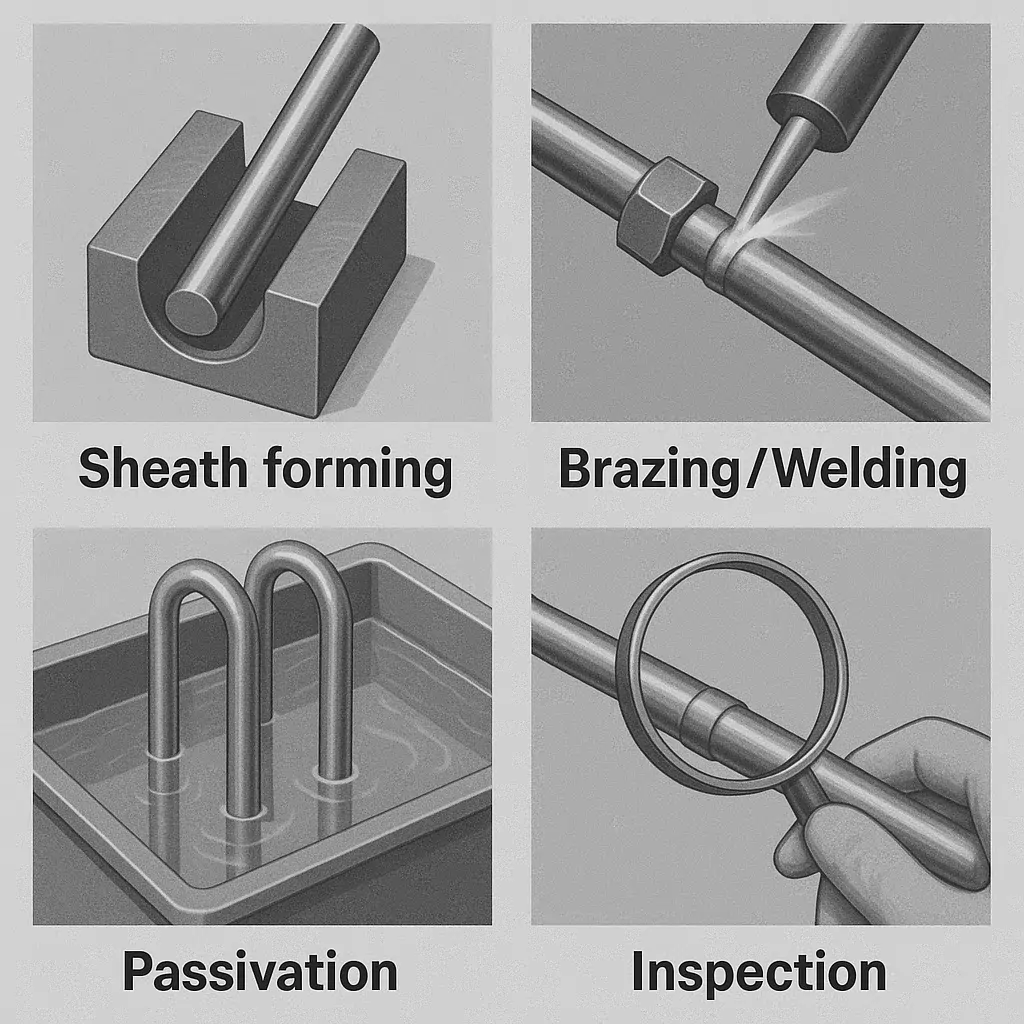

- Reliability — TIG‑welded elements, hydro‑tested heads, replaceable bundles.

- Lifecycle support — commissioning, spares, documentation, FAT.

Immersion Heater Manufacturing Process

Material Selection & Watt Density Guidelines

| Fluid Family | Typical Sheath | Suggested Watt Density | Notes |

|---|---|---|---|

| Potable/DI Water | 316L SS or Copper | 10–20 W/cm² | Consider low W/cm² for hard water; scale control. |

| Light Oils | Incoloy 800/825 | 2–8 W/cm² | Avoid hot spots; maintain flow across elements. |

| Heavy Oils | Incoloy 825 | 1–3 W/cm² | Preheat & recirculation recommended. |

| Caustic/CIP | 316L or Titanium | 4–12 W/cm² | Verify chloride stress corrosion risk. |

| Glycols/HTF | 316L or Incoloy | 3–12 W/cm² | Respect film temperature limits. |

How to Choose the Right Immersion Heater

Define the Duty

Heat‑up load: Q = m · Cp · ΔT. Required power: P = (Q / t) / η + losses with η ≈ 0.95–0.99 for immersion.

Set watt Density

Match to fluid film temperature limit; reduce W/cm² if viscosity or fouling is high.

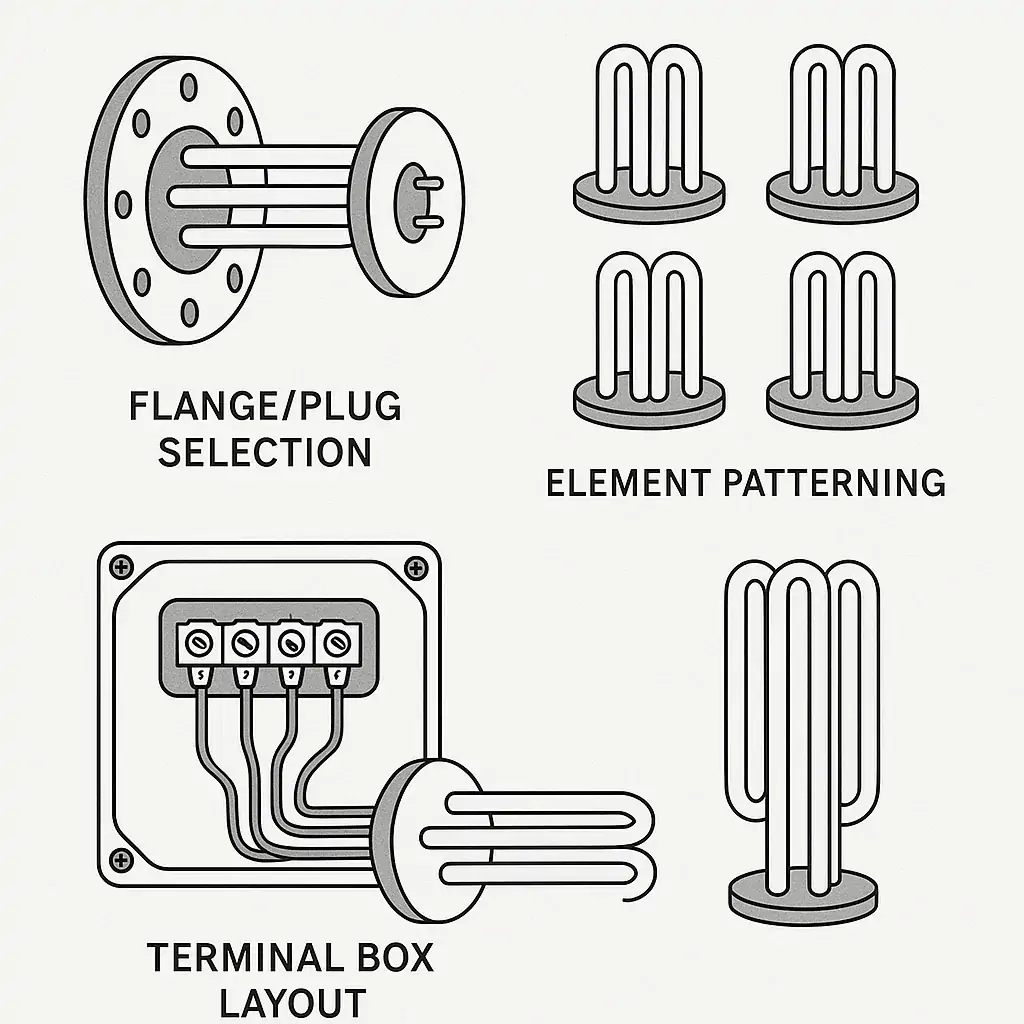

Pick the Mounting

Flanged — high power, pressure‑rated vessels, easy element replacement. Screw‑plug — compact tanks, lower kW. Side‑mount — retrofit, external access, minimal downtime.

Materials & E. Controls

Materials: 316L, Incoloy 800/825, Titanium per corrosion & chlorides. Controls: PID/SCR primary, high‑limit cutout, level interlocks, E‑stop.

Contact Us

Tell us your needs, whether you are a purchaser or an individual buyer, we will arrange professional business people to connect with you.

What Is an Immersion Heater?

An immersion heater is an electric heating element installed directly into a liquid or process tank so heat is transferred at the source. Powered by single- or three-phase supply, sheathed elements convert electrical energy to heat, controlled by thermostats or sensors. Common mountings are flange and screw-plug. Engineers select sheath alloys and watt density to match the fluid, avoid hot spots, and meet safety or hazardous-area requirements.

Immersion Heater Applications

Water & Aqueous Solutions (tanks, rinse baths, DI/RO storage)

Type: flange or screw-plug · Sheath: 316L/copper · Notes: manage scaling; add anodes.Light Oils & Fuels (diesel, hydraulic, lube)

Type: screw-plug or flange · Sheath: Incoloy 800/825 · Notes: low–medium W/cm²; SCR for ramping.Heavy/Viscous Oils (gear, crude, asphalt, bitumen)

Type: high-kW flange bundles · Sheath: Incoloy 825 · Notes: very low W/cm²; recirculation recommended.Chemical Processing (alkalis, caustics, CIP/NaOH, phosphates)

Type: flange/screw-plug · Sheath: 316L or titanium · Notes: verify chloride/SCC; use thermowells.Heat-Transfer Fluids & Glycols (HTF, MEG/TEG)

Type: flange with controls panel · Notes: protect film temperature; add high-limit cutout.Water Treatment (sludge, digesters, sand filters backwash)

Type: side-mount/flange · Notes: corrosion-resistant enclosures; NEMA 4/4X.Food & Beverage (syrups, oils, jacketed tanks, CIP tanks)

Type: sanitary designs · Sheath: 316L · Notes: hygienic seals; tight PID control.Oil & Gas / Hazardous Areas (separators, amine, produced water)

Type: EX d/e assemblies · Notes: ATEX/IECEx/NEC, T-class compliance, instrumentation interlocks.Plating & Surface Finishing (acid/alkaline baths, anodizing)

Type: immersion or side-mount · Sheath: titanium/316L · Notes: chemical compatibility first.Freeze Protection & Maintenance Heat (storage tanks, sumps)

Type: screw-plug/side-mount · Notes: thermostatic control with level/flow interlocks.Power & Utilities (deaerators, condensate, make-up water)

Type: flange · Notes: ASME flanges; redundancy for uptime.

FAQs for Immersion Heaters

Watt density (W/cm²) is power per element surface area; lower values reduce film temperature and protect sensitive fluids.

Yes. ATEX/IECEx/NEC compliant assemblies with EX d/e terminal boxes and T‑class ratings are available.

Match watt density to the fluid, maintain velocity across elements, use PID/SCR control to avoid overshoot, and apply filtration/softening where required.

Yes—UL‑listed panels with PID or SCR, high‑limit safety, level interlocks, alarms, and remote I/O for DCS/PLC.

Typical 2–6 weeks depending on configuration. Deliverables include GA drawings, wiring, IOM manual, and test reports.