Successful Delivery of Explosion-Proof Flange Heaters to Iraq for Oil Heating Applications

Introduction: A Landmark Delivery to Iraq's Oil Sector

In the demanding world of oil and gas, safe and efficient heating of viscous fluids is critical. We are proud to announce the successful delivery of large explosion-proof flange heaters, specifically engineered for oil heating, to a key customer in Iraq. This project highlights our strong capabilities in complex international industrial endeavors, solidifying our position as a leading flange immersion heater supplier for the Middle East market.

Our engagement with this Iraqi customer involved extensive communication and planning, from February to July 2025. This collaborative approach demonstrates our commitment to building deep, trust-based relationships, ensuring we act as a problem-solving partner rather than just a vendor. This article details how we met their critical requirements, from initial contact to final Iraq heater delivery.

Table of Contents

- Introduction: A Landmark Delivery to Iraq's Oil Sector

- Customer Background and Needs: Solving a Critical Challenge

- Product Highlights: Engineered for Performance and Safety

- Manufacturing and Quality Assurance: Built for Reliability

- The Delivery Process: From Our Factory to Iraq's Oil Fields

- Frequently Asked Questions (FAQs)

- Why Partner with Us for Your Industrial Heating Needs?

- Conclusion: Your Trusted Partner for Hazardous Area Heating

Customer Background and Needs: Solving a Critical Challenge for Our Client

Our customer, a prominent oil and gas operator in southern Iraq, faced a significant challenge: their existing heating system for crude oil was inefficient and lacked modern explosion-proof certifications, posing safety risks and causing operational disruptions. They needed a high-performance, reliable industrial heater for oil heating that met strict international safety standards and could be customized for their specific needs.

We engaged in a five-month dialogue with their team. They chose our explosion-proof flange heaters due to our technical expertise, proven track record in hazardous environments, and our commitment to safety and customization. Our comprehensive support, from design to delivery, was key to their decision.

Our Collaborative Dialogue: A Glimpse into Our 5-Month Journey

Below is a selection of chat screenshots that illustrate the detailed, collaborative communication between our team and the customer. These exchanges highlight the technical discussions, problem-solving, and trust-building that were integral to the project's success. From initial inquiries about specifications to discussions on safety features and delivery timelines, every detail was carefully considered.

Product Highlights: Engineered for Performance and Safety

Our custom-engineered explosion-proof flange heaters offer high performance and reliability for demanding oil heating. Key features include:

- Substantial Wattage: Up to 8.5 megawatts for large-scale industrial processes.

- Precise Watt Densities: Tailored for various oil viscosities (1.2 to 3.9 W/cm²), ensuring efficient energy transfer. Elements for this project did not exceed 2.3kW per element for oil heating.

- Global Voltage Compatibility: Wide range of voltages, up to 600V.

- Removable Heating Elements: Allows maintenance without draining the tank, minimizing downtime. This project used 96 elements with 3 spares (99 total).

- Robust Materials: Elements and flanges in Inconel 600, 316 SST, and other high-grade materials for durability.

- Integrated Safety Features: Thermostats, Pt 100 sensors, thermocouples (Type K double element), and a "dehumidifying heater" to prevent moisture in the junction box, ensuring safety and extending lifespan.

- Explosion-Proof Certification: Certified for hazardous environments (ATEX, UKCA, IECEx Zone 1/21, Class 1, Division 1), ensuring safe operation.

- Integrated Control Cabinets: Explosion-proof cabinets house all electrical controls and safety systems, simplifying installation and enhancing safety.

Electric heaters are 100% efficient, transferring all heat to the medium, unlike less efficient fuel-based heaters. They are also more economical, eco-friendly (no harmful emissions), and offer precise temperature control through advanced automation.

Manufacturing and Quality Assurance: Built for Reliability

Our production process ensures top quality and safety for every explosion-proof flange heater and control cabinet:

- Precision Design: Engineered using advanced software to meet exact specifications and hazardous area requirements.

- Material Selection: Only high-grade materials like Incoloy and stainless steels are chosen for durability. We conduct two testing procedures to verify raw material authenticity and quality.

- Expert Manufacturing: Produced in a state-of-the-art facility, adhering to strict quality standards like ASME Section VIII Div. 1 and PED 2014/68/EU.

- Rigorous Quality Tests: Every unit undergoes comprehensive tests, including pressure, insulation, and functional checks, to guarantee flawless performance and safety. We also adhere to NACE MR0175/ISO15156 for materials and welding.

The Delivery Process: From Our Factory to Iraq's Oil Fields

The successful Iraq heater delivery was the result of meticulous planning and execution. Transporting large, sensitive industrial equipment internationally requires sophisticated logistics. Our process began with expert packaging.

Expert Packaging & Crating for Secure Transportation

Our large explosion-proof flange heaters and control cabinets were secured in custom-built, heavy-duty wooden crates. We used internal bracing, shock-absorbing materials, and weatherproof lining to protect the equipment from impacts and environmental factors during transit, ensuring safe arrival and product integrity.

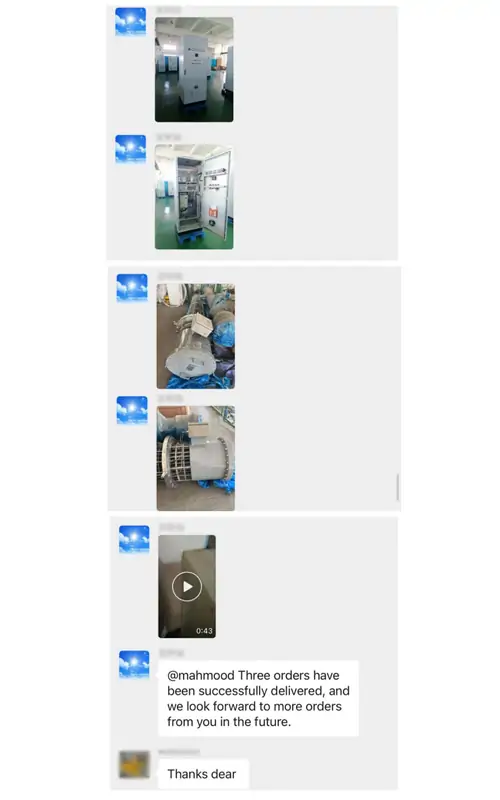

We documented this process with detailed delivery pictures and videos, showcasing our robust packaging and secure anchoring techniques.

Seamless Export Process and Logistics

Navigating international shipping and customs is complex. We partnered with specialized logistics providers experienced in handling oversized industrial cargo for the Middle East. Our team managed all export documentation and ensured compliance, streamlining the customs clearance process for a smooth delivery. The delivery time was adjusted to 30-35 days to ensure thorough quality checks and logistical completion, which our customer valued.

Shipment Photo Gallery

Explore moments captured during the shipment of the explosion-proof flange heaters, highlighting our meticulous attention to detail in packaging, loading, and transit.

"When the heaters finally arrived, perfectly intact and on schedule, it was a huge relief. Seeing them offloaded and ready for installation confirmed we made the right choice. Your team delivered exactly what they promised, from the technical specifications to the complex logistics."

- Our customer's Head of Operations

Frequently Asked Questions (FAQs)

Our flange heaters are designed and certified to safely operate in hazardous environments where flammable gases or dust may be present. They hold international certifications like ATEX, UKCA, and IECEx, ensuring they meet strict safety standards to prevent ignition.

Yes, absolutely. We custom-tailor the watt density and select specific materials (e.g., Inconel 600, 316 SST) for the heating elements and flanges to ensure optimal performance and longevity for various oil viscosities (heavy, medium, or light) and corrosive environments.

Our electric heaters are 100% efficient, meaning all generated heat is transferred directly to the medium. In contrast, fuel-based heaters typically operate at 32%-38% efficiency. This makes electric heaters more economical, eco-friendly (no emissions), and provides more precise temperature control.

While project timelines can vary based on customization and logistical complexities, the delivery for this project was completed within 30-35 days after finalization. We work with specialized logistics providers to ensure safe and compliant international shipping.

No, our heaters feature sheathed removable heating elements. This design allows individual elements to be replaced or maintained without the need to drain the entire tank, significantly minimizing downtime and simplifying maintenance procedures.

Why Partner with Us for Your Industrial Heating Needs?

Our successful delivery of explosion-proof flange heaters to Iraq demonstrates our comprehensive capabilities and commitment to client success. Partnering with us offers several advantages:

- Uncompromising Product Quality & Innovation: Advanced engineering and safety features ensure optimal performance and longevity.

- Rigorous Safety & Global Compliance: Adherence to international standards like ATEX and IECEx guarantees safe operation worldwide.

- Proven Project Management: We navigate complex sales cycles, delivering tailored, high-value solutions from inquiry to delivery.

- Mastery of International Logistics: Our expertise ensures critical equipment arrives safely and on schedule, minimizing your burden.

We are dedicated to customer-centric partnerships, providing reliable solutions and comprehensive support. Our proven track record in demanding international markets sets us apart as a leading flange immersion heater supplier.

Conclusion: Your Trusted Partner for Hazardous Area Heating

The successful delivery of large explosion-proof flange heaters to our Iraqi customer for oil heating is a significant milestone. It highlights our expertise in client engagement, adherence to safety standards, and mastery of global logistics. We deliver customized, technically advanced heating solutions that enhance operational efficiency, reduce downtime, and improve safety for our clients.

Contact our expert team today for a customized explosion-proof heating solution tailored to your specific needs. Discover our full range of capabilities and commitment to excellence.