Are you struggling with heating solutions that corrode easily? Do you need a reliable heater for harsh chemical environments? Then Teflon heaters might be the answer.

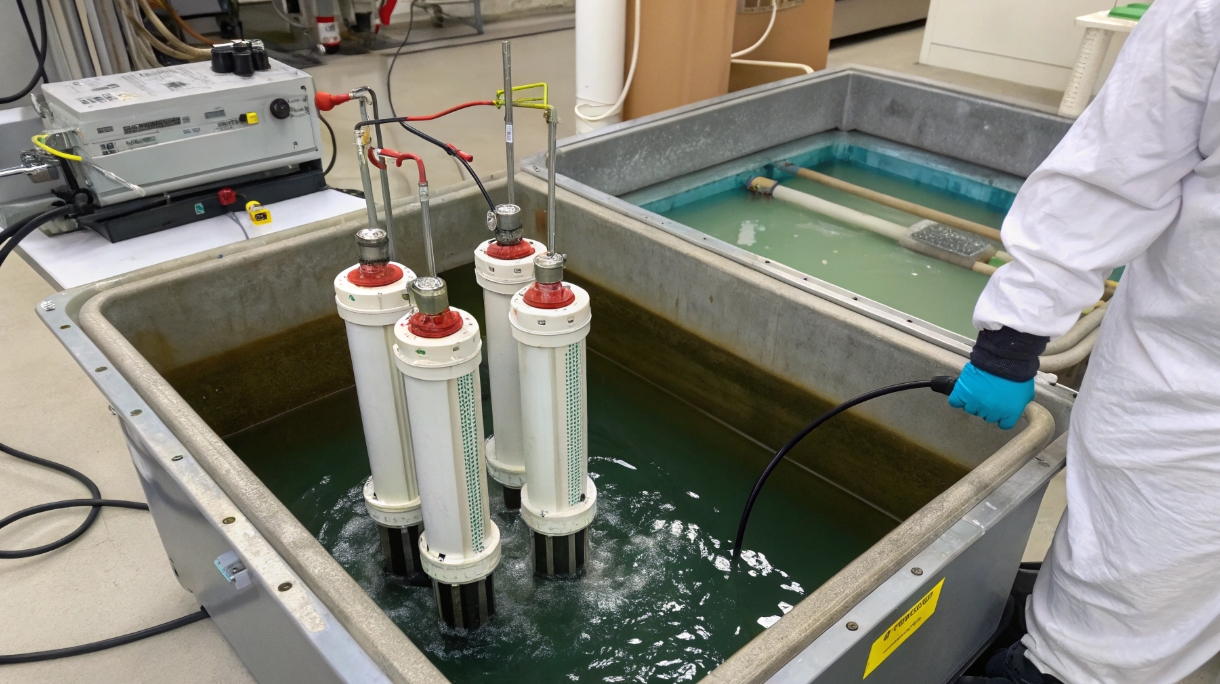

Teflon heaters, also known as PTFE heaters, are designed for corrosive environments. They are often used in industries like chemical processing and electroplating. Their key benefit is their excellent resistance to chemicals, acids, and high temperatures.

So, are Teflon heaters the best option for you? Let’s dive deeper and explore their applications, benefits, and how to choose the right one.

What Are Teflon Heaters?

Are you wondering what makes Teflon heaters so special? What exactly sets them apart from other types of heaters?

Teflon heaters are heating elements coated with Teflon (PTFE). This coating provides exceptional resistance to corrosive chemicals and high temperatures. Because of this, they are ideal for use in harsh industrial environments.

Dive Deeper

The magic of Teflon heaters lies in their unique construction. The PTFE coating is chemically inert. This means it doesn’t react with most substances, which is crucial for industries dealing with aggressive chemicals.

Here’s a breakdown of the typical construction:

| Component | Material | Function |

|---|---|---|

| Heating Element | Usually stainless steel or titanium | Generates heat |

| Insulation | Magnesium oxide (MgO) | Electrically insulates the heating element from the outer sheath |

| Outer Sheath | PTFE (Teflon) | Provides chemical resistance and protects the element from corrosion |

| Terminal Enclosure | Polypropylene or other chemical-resistant material | Houses the electrical connections and protects them from the environment |

When I first started ELEKHEAT, I underestimated the importance of material selection. I quickly learned that choosing the right materials is crucial for heater longevity and performance, especially in corrosive environments. For instance, using standard stainless steel in an acid bath is a recipe for disaster. That’s why Teflon heaters are so vital in certain applications. They provide a reliable heating solution where other materials would quickly fail.

Why PTFE Immersion Heaters Excel in Corrosive Environments?

Why are PTFE immersion heaters the preferred choice for handling corrosive substances? What makes them better than other heating options in such conditions?

PTFE immersion heaters excel in corrosive environments due to Teflon’s exceptional chemical resistance. They can withstand exposure to strong acids, alkalis, and other aggressive chemicals without degrading. This makes them ideal for heating chemical baths and solutions where other materials would corrode.

Dive Deeper

The superior performance of PTFE immersion heaters in corrosive environments is down to several factors, including:

- Chemical Inertness: Teflon (PTFE) is virtually inert. It resists reactions with almost all chemicals, including hydrofluoric acid, one of the most corrosive substances.

- High-Temperature Stability: PTFE maintains its properties at high temperatures (up to around 260°C or 500°F), allowing for efficient heating without degradation.

- Non-Stick Surface: The non-stick nature of Teflon prevents buildup and scaling, which can reduce heating efficiency and shorten the heater’s lifespan.

- Electrical Insulation: PTFE is an excellent electrical insulator, ensuring safe operation even in wet or corrosive environments.

When selecting a PTFE immersion heater, consider the specific chemicals and temperatures involved in your application. For highly aggressive chemicals, you might need to consider additional protective measures, such as grounding or using thicker PTFE coatings. Remember, proper maintenance and regular inspections are key to ensuring the long-term reliability of your heating system.

Choosing the Right Teflon Heater: A Buyer’s Guide for Industrial Use?

How do you choose the best Teflon heater for your specific industrial application? What are the key factors to consider before making a purchase?

When choosing a Teflon heater, consider the chemical compatibility, temperature requirements, and tank size. Check for features like built-in thermostats and over-temperature protection. Also, compare brands like Process Technology and Minco to find the best fit for your needs and budget.

Dive Deeper

Selecting the right Teflon heater involves a careful evaluation of your specific needs. Here’s a more detailed guide:

- Chemical Compatibility: Ensure the PTFE coating is compatible with the chemicals in your process. Check the manufacturer’s specifications for chemical resistance data.

- Temperature Requirements: Determine the maximum operating temperature required for your application and select a heater that can safely handle it.

- Watt Density: Consider the watt density (watts per square inch) of the heater. Lower watt densities are generally better for viscous or heat-sensitive solutions.

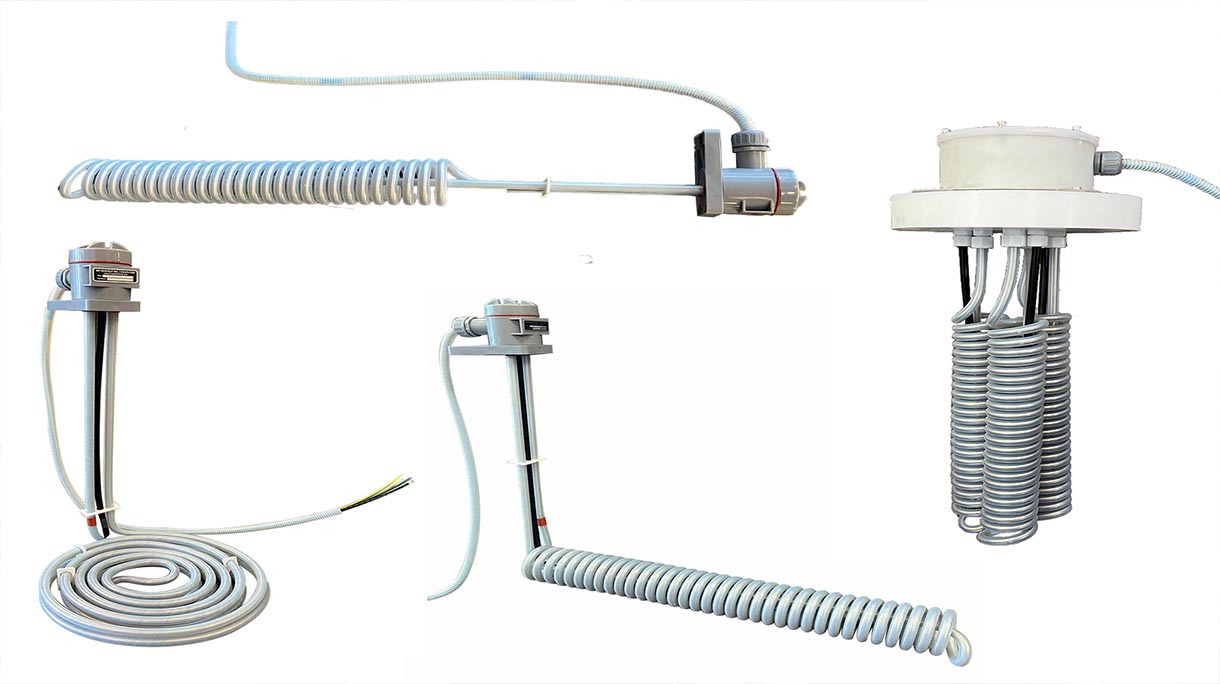

- Tank Size and Shape: Choose a heater size and shape that is appropriate for your tank dimensions. Immersion heaters are available in various shapes, such as L-shaped, over-the-side, and bottom-mounted.

- Control and Safety Features: Look for heaters with built-in thermostats, over-temperature protection, and liquid level sensors to ensure safe and efficient operation.

- Brand and Reputation: Consider established brands like Process Technology and Minco, known for their quality and reliability. However, don’t overlook smaller manufacturers like ELEKHEAT that can offer custom solutions tailored to your specific needs.

When I’m helping customers select a Teflon heater, I always ask about their specific application and operating conditions. Getting these details right ensures they get a heater that performs reliably and lasts a long time.

Conclusion

Teflon heaters offer a reliable solution for heating corrosive liquids. They provide chemical resistance, temperature stability and safe operations.