What is a cartridge heater?

A cartridge heater is a cylindrical industrial heating element designed to ensure precise and localized heating of a machine or object. It is ideal for enclosed spaces or applications that require targeted heat distribution. With customizable power densities and configurations, cartridge heaters are versatile solutions for a variety of industries.

These versatile heaters are designed to be slightly smaller than their nominal diameter for easy installation into drilled cavities. They can also include integrated thermocouples for precise temperature control. And with a variety of diameters to choose from, cooling sections can be customized to meet specific application requirements. Standard power densities are available up to 50W/cm², while specialized high temperature models are available up to 100W/cm².

What are cartridge heaters used for?

Industrial Uses

- Injection molding

- Rubber molding

- Extrusion and die casting

- Immersion Tank Heating

- HVAC Compressors

- Fluid Heating

- Hot Riveting/Punching

Medical applications

- Medical devices

- Sensor Measurement Equipment

Domestic and Commercial Uses

- Food Production

- Plastic Welding

- 3D Printers

Other special applications

- Semiconductors

- Fuel Cells

- Hot melt adhesive equipment

How do cartridge heaters work?

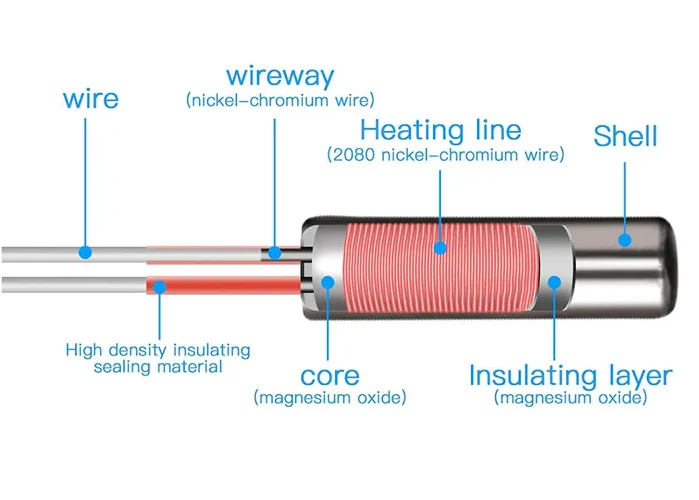

Cartridge heaters operate on the Joule heating principle, in which heat is generated by an electric current flowing through a Nichrome wire to a resistor during operation. The heat is conducted through the MgO insulation to the metal sheath and then transferred to the surroundings or directly to the material to be heated.

Construction of cartridge heaters

- Resistor wire: Nickel-chromium alloy (Nichrome), spiral wound on a ceramic core.

- Insulation: High purity magnesium oxide (MgO) powder.

- Sheath: 304 stainless steel, 316 stainless steel or Incoloy 800.

- Sealing: Seal material selected according to application requirements.

- Terminations and leads: Insulation materials such as fiberglass, silicone rubber, stainless steel braid.

q=k⋅A⋅ΔT/d

- q = heat transfer rate (W)

- k = thermal conductivity (W/m-K)

- A = contact area (m²)

- ΔT = temperature difference (K)

- d = thermal resistance (including the effect of the gap, m)

Elekheat’s expert research analyzes that the tight fit between the sheath and the target material directly affects heat transfer. If the gap is too large, it leads to heat loss and reduced efficiency. The thermal conductivity of the sheath material affects the uniformity and speed of heat transfer. Power density (W/cm²) determines the heat output per unit area. Higher power density is suitable for fast heating and high temperature requirements.

FAQ:

1.What is the operating temperature of cartridge heaters?

Cartridge heaters can operate at low, medium, or high power densities up to 1400°F (760°C). For applications over 1000°F, Incoloy jacketing is recommended.

2.321 SS vs. 304 SS vs. Copper for Cartridge Heater Sheaths?

| Material | Maximum Temperature | Thermal Conductivity | Corrosion Resistance | Mechanical Strength | Cost |

|---|---|---|---|---|---|

| 321 Stainless Steel | 1200°F (650°C) | Medium | Excellent (resistant to oxidation and scaling) | Good | Medium |

| 304 Stainless Steel | 1200°F (650°C) | Medium | Good | Good | Low |

| Copper | 1400°F (760°C) | High | Excellent (for corrosive environments) | Excellent (stable under thermal stress) | High

|

Selection Recommendations

- High temperature/corrosive environments: Copper (best durability and thermal conductivity).

- Medium Temperature/Oxidation Resistant Environments: 321 Stainless Steel (superior overall performance).

- General industrial use: 304 stainless steel (economical solution).

Products

Hi-Density Cartridge Heaters

The standard sheath and end cap materials are either 321 stainless steel or Incoloy 800. The resistance wire is made of Grade “A” nickel-chrome. Elekheat cartridge heaters feature excellent thermal conductivity, along with resistance to corrosion and scaling, providing protection against moisture and other contaminants.

Applications: Precision heating for injection molding, packaging equipment, food processing, medical devices, and industrial heating systems.

Hi-Density Miniature Cartridge Heaters

The standard sheath and end cap materials are either 304 stainless steel. The resistance wire is made of Grade “A” nickel-chrome. Elekheat cartridge heaters offer excellent thermal conductivity, as well as resistance to corrosion and scaling, making them ideal for heating in confined spaces.

Applications: Precision heating for confined spaces, molds, dies, packaging equipment, and laboratory devices.

Low-Density Cartridge Heaters

Low-density cartridge heaters are built with 304 stainless steel sheaths, offering excellent thermal conductivity, high-temperature performance, and resistance to oxidation. The sheath is crimped over a 304 stainless steel end disc, which provides a basic seal but is not moisture-proof.

Applications: Suitable for moderate heat processes in dry environments.

Square and Rectangular Cartridge Heaters

Designed for compact installations, square and rectangular cartridge heaters offer a practical solution for spaces where standard round heaters are not feasible.

Applications: Heating industrial molds, machinery, and presses requiring precise and uniform heating.

Threaded Cartridge Heaters

Threaded cartridge heaters feature a stainless steel sheath and a threaded mount, making them ideal for installations that require a secure and precise fit.

Applications: Used in molds, die-cast equipment, and industrial heating systems.

In-Line Forced Air Heaters

In-line forced air heaters are built for heating air and gas flows in industrial systems. They come in two variations to accommodate different temperature requirements:

- LDA Model: Outlet air temperatures up to 1000°F (538°C), designed for systems with inlet air temperatures not exceeding 250°F (121°C).

- HAC Model: Higher performance with outlet air temperatures reaching 1400°F (760°C), while inlet air temperatures can reach up to 250°F (121°C).

Applications: Heating air in blowers, ducts, and ovens for industrial processes.

Bolt Cartridge Heaters

Bolt cartridge heaters are constructed with high-density swaged heaters, capable of achieving watt densities up to 100 W/in², making them highly efficient for fast heat-up and minimal thermal loss.

Applications: Precision heating for bolting applications, turbine systems, and thermal expansion tasks.