A Complete Guide to Tubular Heaters with Thermostats

An in-depth guide to how tubular heaters work, their construction, applications, and how to select, install, and troubleshoot them.

Table of Contents

What is a tubular heater?

A tubular heater is a heating device. It is shaped like a tube. It uses the principle of Joule heating: when electricity flows through a resistant wire, it creates heat. A tubular heater gives heat in different ways. It can heat by direct touch (conduction), by warming the air (convection), or by sending out heat waves (radiation).

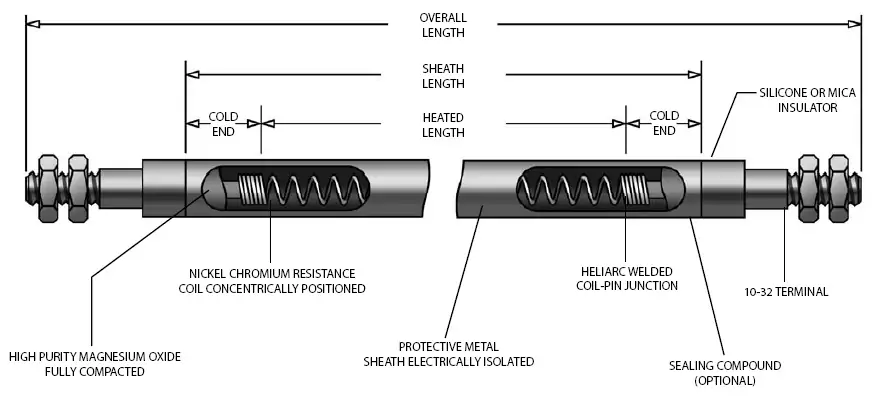

Main Parts of a Tubular Heater

Outer Sheath: The protective metal tube. Its material (copper, steel, Incoloy) is chosen based on the application.

Heating Element: A nickel-chromium (NiCr) alloy wire coil that resists electricity to create heat.

Insulation: High-purity Magnesium Oxide (MgO) powder. It fills the space between the coil and sheath. It transfers heat well but is an excellent electrical insulator, making the heater safe.

Terminals: Connection points (pins or studs) where power is supplied.

How are Tubular Heaters Made?

The manufacturing process is key to the heater's durability and performance.

- Coil Winding: The NiCr resistance wire is precisely wound into a coil.

- Insertion: The coil is centered inside the metal sheath, and terminals are attached.

- Filling: The assembly is filled with high-grade MgO powder.

- Compaction: The entire assembly is compacted using a rolling mill. This reduces the diameter and crushes the MgO powder into a dense, solid mass. This step is critical for good heat transfer and dielectric strength.

- Annealing: The heater is heated in a furnace. This process softens the metal sheath, making it possible to bend into custom shapes.

- Forming: The heater is bent into its final shape.

- Testing: Heaters undergo rigorous testing, including checking for electrical shorts (megohmmeter test) and correct resistance.

The Role of the Thermostat

A thermostat is a control device. It turns a simple heater into an intelligent system that regulates temperature. This is essential for energy efficiency, safety, and process control.

Types of Thermostats

Mechanical (Bimetallic): Uses a strip of two metals that bends with temperature to trip a switch. Simple and cheap, but less accurate.

Digital/Electronic: Uses an electronic sensor (thermistor) for high accuracy. Often includes a digital display.

Capillary Thermostat: Uses a sensor bulb connected to the main body by a long, thin tube (capillary). The tube is filled with a fluid that expands with heat, tripping a switch. This allows the sensor to be placed far from the control dial, which is useful in many applications.

Programmable/Smart: Advanced digital thermostats that allow for scheduling or remote control via Wi-Fi.

How to Choose the Right Thermostat

Selecting the correct thermostat is just as important as selecting the right heater. Here are the key factors to consider:

- Match the Electrical Load: The thermostat must be rated to handle the electrical current (amperage) of the heater(s) it controls. Using an underrated thermostat is a serious fire hazard.

- Consider the Environment: For a damp greenhouse or dusty workshop, you need a thermostat with a suitable IP (Ingress Protection) rating (e.g., IP65).

- Determine Required Accuracy: For simple frost protection, a mechanical thermostat is acceptable. For a sensitive industrial process, a digital thermostat is necessary.

- Select the Right Features: Choose between a simple dial, a programmable schedule, or smart Wi-Fi control based on your needs.

Understanding Hysteresis (Differential)

A thermostat does not turn on and off at the exact same temperature. There is a small gap, called the hysteresis or differential. For example, if you set it to 20°C, it might turn the heater on at 19°C and turn it off at 21°C. This 2°C gap prevents the heater from "short cycling" (turning on and off rapidly), which would wear out the components.

Applications and Uses

The tubular heater is extremely versatile, used in both homes and heavy industry.

Domestic and Light Commercial Uses

- Frost Protection: Greenhouses, sheds, pump houses.

- Damp Prevention: Wardrobes, cellars, boats, RVs.

- Background Heat: Conservatories, cold hallways, animal enclosures.

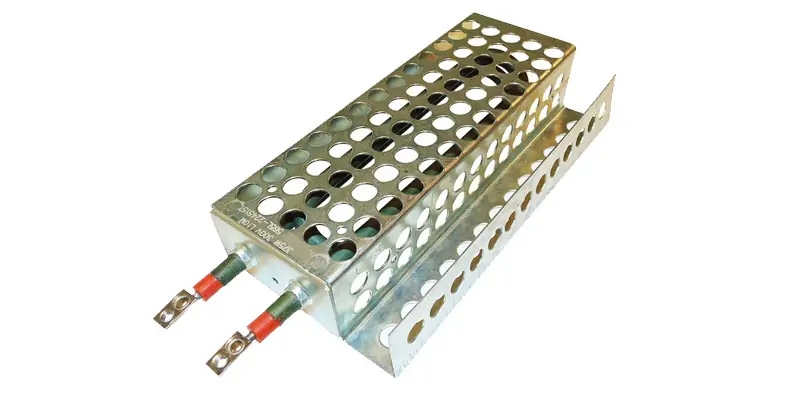

Industrial Uses

- Food and Beverage: Commercial deep fryers, ovens, griddles, sterilization, and pasteurization equipment.

- Plastics and Packaging: Heating platens and molds, thermoforming, heat-sealing bars.

- Manufacturing: Curing resins and epoxies, drying paint, pre-heating parts for welding.

- Medical and Labs: Sterilizers (autoclaves), incubators, environmental chambers.

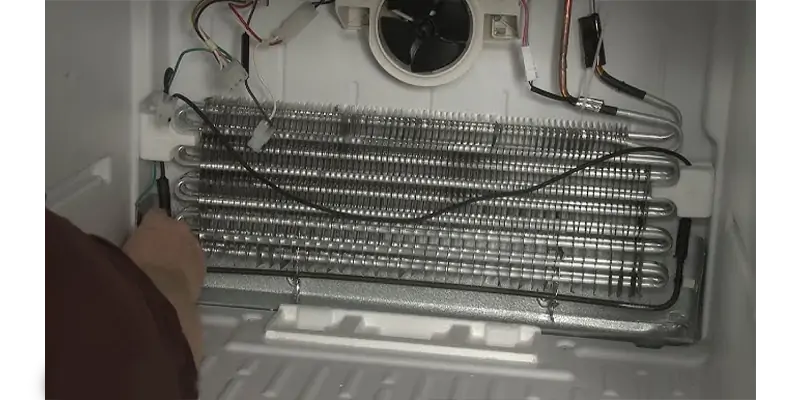

- HVAC and Refrigeration: Duct heaters for air systems, defrosting commercial freezers.

- Oil and Gas: Heating viscous fluids like oil and tar to reduce viscosity for pumping.

Advantages and Benefits

- Energy Efficiency: A thermostat ensures power is used only when needed.

- Precise Control: Maintains stable temperatures required for sensitive applications.

- Safety: Thermostatic control prevents overheating. The sealed construction protects the live element.

- Long Life: The robust, compacted construction resists shock and vibration. Thermostatic control reduces thermal stress, extending the heater's lifespan.

- Versatility: Can be bent to almost any shape and used to heat solids, liquids, or gases.

- Quiet Operation: No moving parts means silent operation, ideal for quiet environments.

Selection Guide - How to Choose the Right Tubular Heater

Choosing the right heater involves matching the heater's specifications to the application's demands.

How do I choose the right size and wattage?

For domestic use, longer heaters have higher wattage (e.g., 60W per foot). For industrial use, wattage calculation is more complex, involving factors like the volume and type of material being heated, heat loss, and required temperature rise. A common approach is to calculate the heat energy required (in kWh) and select a heater that can deliver it in the desired time.

What is Watt Density?

Watt density is the heater's power divided by its surface area (in Watts per square inch or cm). It is the single most important factor for heater longevity. If the watt density is too high for the material being heated, it can cause the material to burn or break down, which then insulates the heater, causing it to overheat and fail.

| Material Being Heated | Max Watt Density (W/in²) |

|---|---|

| Water (Clean) | 60 - 100 |

| Vegetable Oil | 20 - 30 |

| Hydraulic/Lube Oil | 15 - 25 |

| Asphalt / Tar | 3 - 5 |

| Forced Air (e.g., Duct Heater) | 25 - 120 (depends on velocity) |

| Natural Convection Air | 5 - 10 |

Choosing Sheath Materials

The sheath must resist corrosion from the medium and withstand the operating temperature.

| Sheath Material | Common Applications |

|---|---|

| Copper | Clean water heating. Low temperature. |

| Steel | Oils, waxes, tar, non-corrosive solutions. |

| Stainless Steel (304/316) | Food industry, corrosive liquids, process water. |

| Incoloy® (800/840) | High-temperature air heating, hard water, excellent corrosion resistance. |

Terminal and Sealing Options

The way power is connected and how the ends are sealed is critical, especially in wet or contaminated environments.

| Type | Description |

|---|---|

| Threaded Studs | Most common. Allows secure connection with nuts and ring terminals. |

| Lead Wires | Flexible wires extend from the heater. Good for applications with vibration. |

| Epoxy Seal | Good general-purpose seal against moisture and contamination. |

| Silicone/RTV Seal | More flexible than epoxy, good for higher temperatures and vibration. |

| Ceramic-to-Metal Seal | Hermetic seal for very high temperatures or vacuum applications. |

Bending and Forming Considerations

While tubular heaters are bendable, there are rules. Bends cannot be too tight (the minimum bend radius depends on the sheath diameter). Also, the ends of the heater containing the terminals (the "cold pins") are unheated and generally cannot be bent.

Installation and Maintenance

Proper installation is critical for safety and performance. Maintenance is minimal but important.

How to Install the Tubular Heater

- Disconnect Power: Always de-energize circuits before work.

- Mount Horizontally: Most tubular heaters must be mounted horizontally unless the manufacturer states otherwise.

- Mount Securely: Use the provided brackets. Allow for slight thermal expansion.

- Maintain Clearances: Do not cover the heater. Ensure adequate airflow and keep it away from flammable materials.

- Use a Guard: If the heater is accessible, a safety guard is strongly recommended.

How to Install the Thermostat

Installing an external thermostat to control your heater(s) must be done by a qualified electrician. The basic steps are:

- Choose the Right Location: The thermostat should be placed on an interior wall, at average height, in a spot with good air circulation. Do not place it in direct sunlight, near drafts, or too close to the heater itself, as this will give false temperature readings.

- Turn Off Power: Before any wiring, shut off the power to the circuit at the main electrical panel.

- Mount the Thermostat: Securely mount the thermostat base to the wall.

- Wire the Circuit: The thermostat acts as a switch. The live wire from the power supply goes to the "Live In" terminal of the thermostat. A second wire goes from the "Live Out" (or "Load") terminal of the thermostat to the live terminal of the heater. The neutral and earth wires typically bypass the thermostat and connect directly between the power supply and the heater.

- Restore Power and Test: Once all connections are secure, restore power and test the system by adjusting the thermostat to ensure it correctly switches the heater on and off.

Troubleshooting Common Issues

| Problem | Possible Cause | Solution |

|---|---|---|

| Heater not heating | No power / tripped breaker | Check power source, reset breaker. |

| Faulty thermostat or wiring | Check thermostat settings and wiring connections. | |

| Open circuit in heater (burned out) | Check resistance with a multimeter. If infinite, replace heater. | |

| Breaker trips immediately | Short circuit (element to sheath) | Use a megohmmeter to check insulation. If failed, replace heater. |

| Heater fails prematurely | Watt density too high / contamination | Review application. Select a lower watt density heater or improve filtration. |

Safety Standards and Certifications

Reputable heaters are tested and certified by third-party organizations to ensure they meet strict safety standards. Look for these marks:

- UL (Underwriters Laboratories): A primary standard in North America, particularly UL 499 for electric heating appliances.

- CSA (Canadian Standards Association): The equivalent standard for Canada.

- CE Marking: Declares conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

Comparative Analysis

The best heater is the one that is right for the job. All electric heaters are nearly 100% efficient at converting electricity to heat; the difference is in how they deliver that heat.

| Feature | Tubular Heater | Fan Heater | Oil-Filled Radiator | Quartz/Infrared |

|---|---|---|---|---|

| Heating Method | Convection | Forced Convection | Convection/Radiation | Radiation |

| Speed | Medium | Very Fast | Very Slow | Instant |

| Noise Level | Silent | Noisy | Silent | Silent |

| Best For | Fixed background heat | Quick room heating | Steady, long-term heat | Heating objects/people directly |

Consolidation of Key Information

What is a tubular heater?

A robust, tube-shaped electric heater used for low-level background heat or precise industrial process heating.

Why is a thermostat essential?

It provides temperature control, which saves energy, improves safety by preventing overheating, and extends the heater's life.

What is the most important selection factor?

Watt density. Choosing a watt density that is too high for the application is the most common cause of premature heater failure.