Are you struggling to maintain consistent temperatures in your industrial processes? Many industries face this issue, and platen heaters might be the solution.

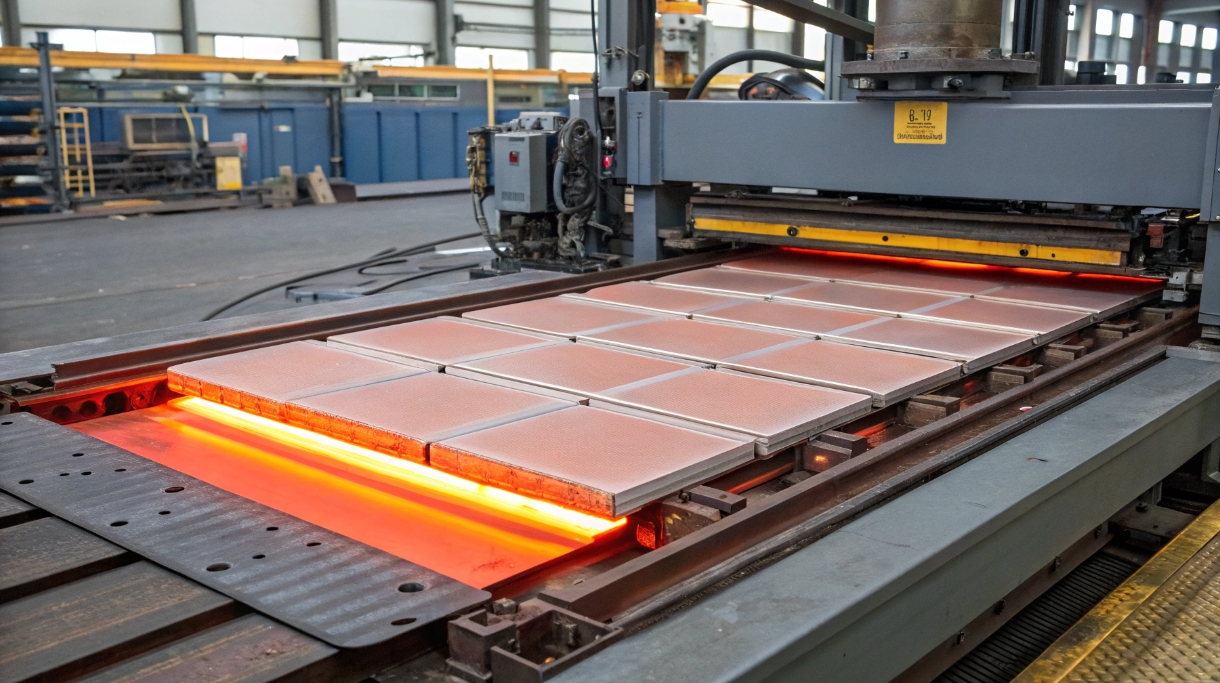

Platen heaters are flat, heated plates used to transfer heat evenly to a specific surface or material. They come in various types, including cast-in, high-temperature, and cartridge heaters, each designed for different applications.

So, if you’re looking for an effective way to improve your heating process, keep reading to learn more about platen heaters.

What Is a Platen Heater? Types, Components, and Key Applications?

Do you know that platen heaters are not all the same? They come in different shapes and sizes, each with its own unique features and uses.

A platen heater is a flat, electrically heated plate used to provide uniform heat to a surface. The main types include cast-in heaters (aluminum or bronze), which offer excellent temperature uniformity, and high-temperature heaters, which are designed for applications needing extreme heat. Key components are the heating element, insulation, and mounting hardware. These heaters are used in industries like plastics, food processing, and printing.

What materials are commonly used for platen heaters?

Platen heaters use a variety of materials. These materials help meet different application needs.

| Material | Properties | Typical Applications |

|---|---|---|

| Aluminum | Good thermal conductivity, lightweight, corrosion-resistant | Food processing, packaging |

| Bronze | Excellent thermal uniformity, durable, corrosion-resistant | Plastic molding, rubber processing |

| Stainless Steel | High-temperature resistance, corrosion-resistant, hygienic | Medical equipment, cleanroom environments |

| Alloy | High-temperature strength, oxidation resistance | Semiconductor manufacturing, aerospace |

When I first started in this industry, I was surprised by how much the material choice impacts the heater’s performance. For example, aluminum platens heat up quickly. Bronze platens maintain a more consistent temperature. The choice really depends on what you’re trying to achieve. We once had a client in the food processing industry who switched to stainless steel platen heaters. This significantly improved the hygiene and lifespan of their equipment.

Top 10 Industrial Uses for Platen Heaters (And Which Types Work Best)?

Are you curious about where platen heaters are used in the real world? You might be surprised at the variety of applications.

Platen heaters are essential in many industries. They are used in plastic molding, food processing, printing, packaging, and semiconductor manufacturing. Cast-in heaters are ideal for plastic molding because they offer uniform heating. High-temperature heaters are used in semiconductor manufacturing for processes that need extreme heat. Choosing the right type of heater can significantly improve efficiency and product quality.

Which industries benefit most from platen heaters?

Platen heaters are versatile tools that improve efficiency and quality in many sectors.

| Industry | Application | Type of Platen Heater | Benefits |

|---|---|---|---|

| Plastic Molding | Heating molds for plastic injection | Cast-in Heaters | Uniform temperature distribution, prevents warping |

| Food Processing | Sealing and packaging food products | Aluminum Platen Heaters | Consistent sealing, maintains food safety |

| Printing | Heating printing plates | High-Temperature Heaters | Accurate temperature control, improves print quality |

| Packaging | Sealing and forming packages | Cartridge Heaters | Localized heating, energy-efficient |

| Semiconductor | Wafer processing and testing | Alloy Platen Heaters | High-temperature stability, precise temperature control |

| Rubber Manufacturing | Vulcanizing rubber products | Bronze Platen Heaters | Uniform heating, durable |

| Textile Industry | Heat pressing and bonding fabrics | Flexible Heaters | Even heat distribution, prevents scorching |

| Automotive | Laminating interior components | Cast-in Heaters | Consistent bonding, high-quality finish |

| Aerospace | Composite material curing | High-Temperature Heaters | High-temperature stability, ensures structural integrity |

| Medical Equipment | Sterilizing medical instruments | Stainless Steel Platen Heater | Maintains hygiene, corrosion-resistant |

I remember one time we were working with a client who made plastic parts for cars. They were having problems with the plastic warping during the molding process. We suggested they switch to cast-in heaters, which distribute heat more evenly. This simple change completely solved their problem and improved the quality of their parts.

Conclusion

Platen heaters are essential for industries needing consistent and efficient heating, improving product quality and process efficiency.