Cartridge Heaters Explained | Types, Watt Density & Industrial Uses

Learn about cartridge heating elements: how they work, their types, uses, and how to choose and maintain them for industrial efficiency. Essential for engineers, managers, and OEMs.

What are Cartridge Heaters?

How They Work

Cartridge heaters are tough, cylindrical heating elements used to heat things precisely in industrial settings. They fit into drilled holes in metal parts, delivering heat exactly where it's needed.

These heaters are used in many industries, from making plastics and packaging to medical devices, lab equipment, and even car and airplane parts. They solve the problem of needing focused heat in small or specific areas, making them a key tool for many industrial tasks.

Unlike tubular heaters that spread heat over large areas, cartridge heaters are designed for direct, focused heat. They're perfect for jobs where you need intense heat in a small spot.

Parts of a Cartridge Heater

A cartridge heater is built with several key parts:

- Heating Coil: The part that gets hot, usually made of Nickel-Chromium (Nichrome) or Kanthal wire.

- Insulation: Magnesium Oxide (MgO) powder packed around the coil to prevent shorts and help transfer heat.

- Sheath: The outer metal casing (like stainless steel or Incoloy) that touches what's being heated. The material depends on the heat and environment.

- Sealing: Protects the inside from moisture and dirt. Different seals are used for different temperatures and conditions.

- Lead Wires: Connect the heater to power. They come with various protections (like springs or metal braids) to handle heat or movement.

- Cold Section: An unheated part at the ends that protects the lead wires from too much heat.

These heaters are built to last in tough industrial environments. Choosing the right materials and protective features is important for long life and avoiding costly failures.

Cartridge Heater Internal Structure

Technical Details & Types

Watt Density: Power and Efficiency

Watt density tells you how much heat a heater puts out per square inch. It affects how fast the heater gets hot, how efficient it is, and how long it lasts. Too much watt density can cause overheating, while the right amount ensures long-term performance.

Cartridge heaters come in different watt density levels:

- High Watt Density (100-400 W/in²): Heats up very fast and reaches high temperatures (up to 1400°F). Great for tight spaces and quick heating needs, like in plastic molding machines. Needs a very snug fit in the hole for best results.

- Medium Watt Density (40-76 W/in²): A good all-around choice for general heating where super-fast heating isn't critical.

- Low Watt Density (5-45 W/in²): For slower, gentler heating in sensitive areas or at lower temperatures. Often more affordable.

The fit of the heater in its hole is crucial, especially for high watt density heaters. A loose fit means poor heat transfer, causing the heater to get too hot inside and fail sooner. Choosing the right watt density means balancing speed with heater life and proper installation.

You can calculate watt density using this formula: Watt density = Wattage / (π x Diameter x Heated Length).

Cartridge Heater Watt Density Calculator

Cartridge Heater Categories by Watt Density

High Watt Density

Range: 100-400 W/in²

Fast heating, high temps. Ideal for tight spaces.

- Rapid heat-up

- High-temperature applications (up to 1400°F)

- Ideal for confined spaces

Medium Watt Density

Range: 40-76 W/in²

Good balance of heat and safety for general use.

- Balanced performance

- General-purpose heating

- Good for applications not requiring rapid cycling

Low Watt Density

Range: 5-45 W/in²

Slower, even heating for sensitive or lower-temp jobs.

- Slower, uniform heating

- Sensitive environments

- Lower to mid-temperature uses

- Generally more economical

Our Cartridge Heater Products

High Watt Density Cartridge Heater

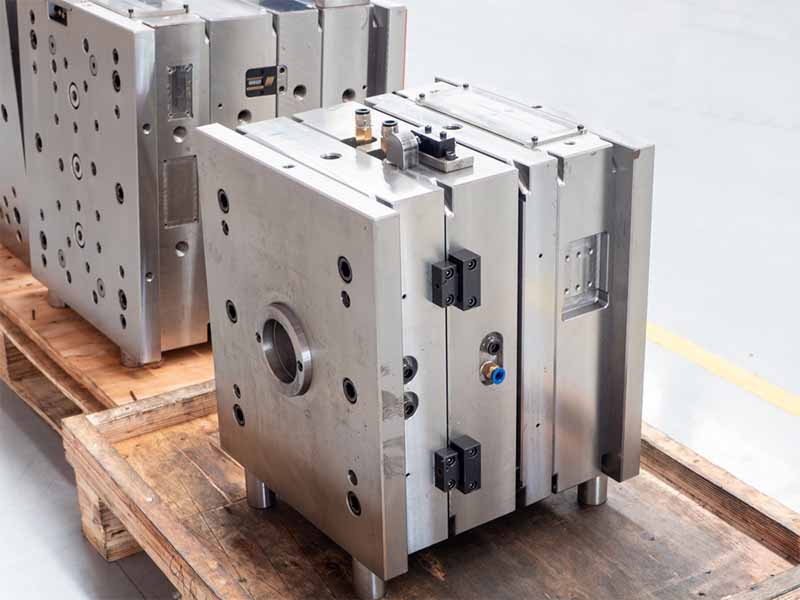

Designed for demanding applications requiring rapid and intense heat. Ideal for molds, dies, and hot runner systems.

Standard Cartridge Heater

A versatile and reliable choice for general heating tasks across various industrial processes. Balances performance and cost.

Immersion Cartridge Heater

Specifically designed for heating liquids and gases. Features robust sealing for fluid environments.

Custom Cartridge Heater

Tailored to your exact specifications for unique applications, ensuring optimal integration and performance.

Medical Grade Cartridge Heater

Meets stringent medical industry standards for precision, reliability, and sanitation in sensitive equipment.

Aerospace Grade Cartridge Heater

Built for extreme conditions in aerospace applications, offering high durability and consistent performance.

Size and Fit for Best Heat Transfer

The heater's size and how well it fits into its hole are vital for efficient heat transfer and long life. A loose fit means poor heat transfer and early failure. A too-tight fit can make installation and removal hard.

Heaters are made slightly smaller than their stated size for easier fitting. Precise drilling and reaming of holes are key, especially for high-heat applications, to ensure maximum contact. Remember that heaters expand when hot, which helps them fit snugly.

Getting the fit right is crucial. A good fit saves money in the long run by making the heater more efficient and lasting longer. Always follow supplier recommendations for the best fit.

Choosing the Right Materials

The materials used in a cartridge heater affect how durable and well it performs in different industrial settings.

- Sheath Materials: The outer casing (sheath) is often stainless steel (304, 316, 321) for corrosion resistance. For very high temperatures or harsh chemicals, stronger alloys like Incoloy or Inconel are used. Brass and Titanium are options for special needs.

- Insulation: High-purity Magnesium Oxide (MgO) powder keeps the electrical parts safe and transfers heat well.

- Resistance Wire: Nickel-Chromium (Nichrome) or Kanthal alloys are used for the heating coil because they convert electricity to heat efficiently and can handle high temperatures.

Material choice depends on the heat needed, max operating temperature, and environmental conditions (like chemicals or vibration). Choosing the right materials and protective features is key for heater survival and reliable performance in tough conditions. It's about ensuring the heater can withstand its specific job environment to avoid costly failures.

Sheath Material Comparison Tool

Electrical Setup & Certifications

Cartridge heaters come with various electrical setups and certifications to ensure safety and performance.

- Voltage: Common voltages are 120V, 230V, and up to 480V AC. Higher voltages might need lower watt densities. Three-phase power and dual-voltage options are also available.

- Lead Wires & Protection: Wires connect to power. Types like fiberglass or silicone are chosen based on temperature and wear. Protections like strain relief or metal braiding keep them safe from damage.

- Termination Styles: How the wires connect to the heater (straight, right-angle, threaded posts).

- Built-in Thermocouples: Some heaters have built-in sensors (thermocouples) for precise temperature control and to prevent overheating. This makes them "smart" components, improving process stability and product quality.

- Certifications: Reputable makers get certifications like UL, CSA, and CE. These show the products meet strict safety and performance rules.

Common Wiring Diagrams

Single Heater (2-Wire)

Basic connection for one heater to a single-phase power supply.

Two Heaters in Series

Connects two heaters end-to-end. Total resistance increases, reducing power for each heater.

Two Heaters in Parallel

Connects two heaters side-by-side. Each heater gets full voltage, increasing total power.

Three Heaters: Wye (Star)

For three-phase power, heaters connect to a common neutral point.

Three Heaters: Delta

For three-phase power, heaters connect in a triangular configuration.

Where Cartridge Heaters Are Used

In Manufacturing

Cartridge heaters are key for precise heating in many manufacturing processes:

- Molds, Dies, and Platens: Used to heat these metal parts evenly.

- Hot Runner Systems: Keep plastic molten in injection molding nozzles and molds, improving part quality.

- Heat-Sealing Jaws & Cutting Blades: For clean sealing and cutting in packaging machines.

- Hot Stamping & Thermoforming: Heat materials for shaping and detailing.

In 3D Printers & Plastic Molding

Their ability to provide focused heat in small areas makes them vital for advanced machines:

- Plastic Injection Molding: Heat molds and nozzles for even plastic flow and to prevent defects.

- 3D Printers: Provide stable heat for the hotend and heated bed, crucial for proper filament extrusion and print quality, especially for high-performance materials. They also help printers heat up faster.

Their use in these high-tech areas shows they're essential for precision and efficiency in modern manufacturing. For companies making these machines (OEMs), cartridge heaters are a core part of their product's performance.

For Liquids and Gases

Beyond solids, cartridge heaters can also heat liquids and gases. They're used in small tanks, medical fluid warmers, and food processing equipment.

Specialized & Medical Uses

Their durability and precision make them useful in demanding fields:

- Aerospace and Automotive: For engine warming, hydraulic systems, and de-icing.

- Food Processing: For heat sealing, warming trays, and liquid dispensing.

- Medical Devices: For sterilization, fluid warming, and lab instruments, where precise, clean heat is critical.

- Semiconductor & Scientific Equipment: For precise heating where even tiny temperature changes matter.

Why Use Cartridge Heaters? (Benefits)

Cartridge heaters offer many benefits, making them a top choice for industrial heating:

Precise & Even Heat

They deliver very focused and even heat, preventing hot or cold spots. This is vital for processes needing exact temperature control.

Fast Heating

They heat up quickly, often in minutes, reducing warm-up times and production delays. This means more efficient operations.

Small Size

Their compact, cylindrical shape allows them to fit easily into tight spaces and complex machines, optimizing space.

Durable

Built with strong materials like stainless steel, they resist corrosion, stress, and vibration, ensuring a long life in tough conditions. Proper installation helps them last even longer.

Customizable

You can customize their wattage, voltage, size, wire types, and materials. This means a perfect match for your specific needs, ensuring best performance.

Energy Efficient

They transfer heat directly, minimizing waste and saving energy. A tighter fit makes them even more efficient.

Easy to Replace & Maintain

Simple to install and remove, they make maintenance easier and reduce downtime.

Overall, cartridge heaters offer lower long-term costs due to their efficiency, long life, and easy maintenance. This makes them a smart financial choice for industrial operations.

How to Choose the Right Heater

Choosing the right cartridge heater is key for efficiency and costs. Here’s a step-by-step guide:

Understanding Your Needs

First, know what your application requires:

- Material: What are you heating (metal, plastic, liquid, gas)?

- Temperature: What exact temperature do you need, and what's the max the heater can handle?

- Heat Output (Watt Density): How much heat per square inch is needed, considering how fast it needs to heat up and space limits?

- Voltage: What power supply do you have?

- Environment: Will it be exposed to moisture, chemicals, vibration, or vacuum?

- Performance: How fast should it heat up? How even should the heat be? How long should it last?

Matching Specs to Goals

Once you know your needs, pick the right heater features:

- Watt Density: Choose high, medium, or low based on speed, space, and material sensitivity.

- Dimensions: Measure the hole precisely. The heater length should match the heated area, considering expansion when hot.

- Sheath Material: Pick based on temperature, corrosion, and stress. Incoloy for very high temps, stainless steel for general use.

- Lead Wires & Sealing: Select wire type and protection based on ambient temperature, moisture, and movement.

- Temperature Control: Consider heaters with built-in thermocouples or use external sensors for precise control and safety.

- Power Control: Use advanced controls (like PID) to reduce on/off cycling, which helps the heater last longer.

Choosing Suppliers

Picking a good supplier is as important as picking the heater itself. A good supplier is a partner who helps with design, supply, and support.

- Quality: Look for manufacturers with a history of high-quality products and strict quality checks.

- Certifications: Make sure their products have certifications like UL, CSA, and CE for safety and market access.

- Customization: Can they make heaters to your exact specs (wattage, length, materials, etc.)? This is crucial for unique systems.

- Technical Support: Do they offer help with selection, design, and troubleshooting?

- Lead Times: How long will it take to get your order, especially custom ones?

- After-Sales Support: Do they offer good support, warranties, and spare parts?

- Cost-Effectiveness: Look beyond the initial price to the total cost over time, including energy use and maintenance.

A strategic supplier is a partner who helps you with design, supply chain, and technical support, leading to better long-term growth and efficiency.

Cartridge Heater Supplier Evaluation Checklist

| Category | Criteria | Importance for Buyers |

|---|---|---|

| Quality & Reliability | Proven Track Record | Consistent product performance, trustworthy. |

| Industry Certifications (UL, CSA, CE) | Ensures safety, meets standards, helps market access. | |

| Material Quality | Affects durability and performance in tough jobs. | |

| Manufacturing Process (e.g., swaging, quality control) | Ensures consistent, efficient, and reliable heaters. | |

| Customization & Engineering | Range of Customization Options | Allows precise matching for best performance. |

| Technical Design Support | Expert help for complex designs and integration. | |

| R&D Capabilities | Shows commitment to new solutions and future needs. | |

| Support & Service | Pre-Sales Technical Assistance | Helps with correct heater choice and planning. |

| After-Sales Support, Warranty & Guarantees | Ensures ongoing support, reduces downtime, protects investment. | |

| Repair & Maintenance Services, Spare Parts | Quick fixes, extends heater life, lowers long-term costs. | |

| Logistics & Supply Chain | Standard Lead Times, Rush Order Capabilities | Important for planning and urgent needs. |

| Stock Availability | Reduces waiting times for common heaters. | |

| Inventory Management, Global Shipping | Ensures reliable supply, supports international operations. | |

| Cost & Value | Transparent Pricing | Clear costs, no hidden fees. |

| Long-Term Cost-Effectiveness (TCO) | Considers energy use, durability, and maintenance for total cost. | |

| Payment Terms, Bulk Order Discounts | Helps with budgeting and large orders. |

Lead Times & Availability

Knowing how long it takes to get heaters is important for planning.

- Custom vs. Stock: Standard heaters are often in stock. Custom ones are made to order.

- Typical Lead Times: Custom orders can take 7 to 25 working days, depending on complexity.

- Rush Options: Many suppliers offer faster delivery (24 hours to 8 days) for urgent needs, but it might cost more.

- Factors Affecting Time: Factory workload and custom features can change delivery times. Always confirm with your supplier.

Installation, Maintenance & Troubleshooting

How you install and maintain cartridge heaters greatly affects how long and well they work. Regular care prevents problems and saves money.

Installation Tips

Correct installation is key for heater efficiency and life:

- Proper Fit: The heater must fit snugly in the drilled hole for best heat transfer. Avoid air gaps.

- Hole Prep: Drill and ream holes accurately for a tight fit. Through-holes make removal easier later.

- Lubricants: Use lubricants carefully; they must be completely dry before insertion to prevent damage.

- Wiring: Follow all electrical codes. Ensure connections are tight and voltage matches the heater.

- Temperature Control: Use sensors (thermocouples) and controllers for precise heat management and to prevent overheating.

- Protection: Keep leads and heater ends safe from moisture, oil, and chemicals.

- Heat Sink: Heaters need direct contact with a metal part to transfer heat; never run them in open air.

Routine Maintenance

Regular maintenance extends heater life:

- Monitor: Check regularly for wear, discoloration, or damage.

- Electrical Checks: Tighten connections and test continuity to catch issues early.

- Clean: Keep heater ends and leads free of dirt and residue.

- Calibrate: Regularly check temperature controls for accuracy.

- Qualified Staff: Only trained personnel should do maintenance.

Common Issues & Fixes

Even tough heaters can have problems. Here are common ones and how to fix them:

- Uneven Heating: Check for damaged elements, poor fit, or insulation issues.

- Early Failure/Blown Fuses: Often caused by poor fit, wrong voltage, bad temperature control, or contamination. Too much on/off cycling also shortens life.

- Overheating: Could be a bad thermostat, blocked exhaust, or poor airflow.

- Stuck in Hole (Bore Seizure): Happens when the heater expands and gets stuck. Use through-holes or special "split sheath" heaters for easier removal. Anti-seize coatings can also help.

- Lead Wire Failure: Wires can fail from too much heat or movement. Use high-temp wires, cold sections, or protective coverings.

- Not Heating Enough: Check power, connections, voltage, and insulation.

- Corrosion: Look for corrosion on elements. Replace faulty parts.

Making Them Last Longer

To get the most out of your heaters:

- Optimal Temperature: Run them below their max rated temperature when possible.

- Controlled Watt Density: Use watt densities below the maximum recommended.

- Minimize Cycling: Use precise temperature controls (like PID) to reduce frequent on/off cycles.

- Maintain Fit: Keep the fit tight in the hole for efficient heat transfer.

- Protect from Contamination: Prevent moisture, oil, or debris from getting inside.

- Manage Wires: Avoid excessive bending and protect lead wires from heat or wear.

Safe Removal

When replacing a heater, follow these steps:

- Power Off & Lock Out: Always turn off and lock out power first.

- Cool Down: Let the heater cool to a safe temperature.

- Access: Open panels and disconnect wires.

- Loosen: Remove fasteners. Gently twist or tap if stuck. Heating the block carefully can help.

- Through-Hole Advantage: If the hole goes all the way through, you can often push the heater out.

- Split Sheath Heaters: These are designed for easy removal, especially if you need to replace them often.

For OEMs: Integration & Partnerships

For companies that build equipment (OEMs), choosing cartridge heaters is a key design choice. This often means building strong, long-term relationships with heater manufacturers.

Customization for OEMs

OEMs often need parts tailored to their systems. Heater makers offer many custom options:

- Tailored Design: Exact sizes, wattages, voltages, wire types, and materials.

- Advanced Features: Options like distributed wattage (for even heat), no-heat sections (to protect wires), multi-phase power, and built-in sensors.

Because OEMs need such specific solutions, standard heaters often won't do. Custom heaters are crucial for top performance and a competitive edge. OEMs should view heater makers as design partners.

Why Partner with Manufacturers

The relationship between OEMs and heater manufacturers has become a true partnership:

- Shared Innovation: Manufacturers can help with product design, leading to better, cheaper products and faster development.

- Flexible Operations: A good partner can adjust production for changing demand, ensuring you always have parts.

- Expertise: Manufacturers provide deep technical knowledge and help meet strict industry standards.

- Reliable Supply: Good logistics mean consistent part availability and fewer delays.

- Long-Term Support: Partners offer ongoing help, troubleshooting, and maintenance programs.

- Cost Savings: Smart partnerships lead to long-term savings through better design, efficiency, and less downtime.

For OEMs, choosing a heater manufacturer means picking a strategic ally who helps with innovation, growth, and overall business strength.

Frequently Asked Questions (FAQ)

Q: What is a cartridge heater used for?

A: Cartridge heaters are used for precise, localized heating in industrial applications like plastic molding, packaging machinery, 3D printers, medical devices, and more. They deliver concentrated heat to specific areas.

Q: How does a cartridge heater work?

A: They work by passing an electric current through a resistance coil (usually Nichrome or Kanthal), which generates heat. This heat is then efficiently transferred through insulation and an outer metal sheath to the object being heated.

Q: What is "watt density" and why is it important?

A: Watt density is the heat output per square inch of the heater's surface. It's important because it affects how fast the heater heats up, its efficiency, and its lifespan. High watt density means faster heating but requires a very snug fit to prevent overheating.

Q: What materials are cartridge heater sheaths made from?

A: Common sheath materials include various stainless steels (304, 316, 321) for general use and corrosion resistance. For very high temperatures or harsh environments, superalloys like Incoloy or Inconel are used. Brass and Titanium are also used for specific applications.

Q: Can cartridge heaters be customized?

A: Yes, cartridge heaters are highly customizable. You can specify wattage, voltage, dimensions, lead wire types, termination styles, sheath materials, and even add features like built-in thermocouples to meet unique application needs.

Q: How can I extend the life of my cartridge heater?

A: To extend heater lifespan, ensure a proper, tight fit in the bore, operate below maximum rated temperature, minimize on-off cycling (use PID controllers), protect from contamination (moisture, oil), and manage lead wires to prevent stress.

Q: What should I consider when choosing a cartridge heater supplier?

A: Look for suppliers with a proven track record of quality, relevant certifications (UL, CSA, CE), strong customization capabilities, excellent technical support, reliable lead times, and comprehensive after-sales service. Consider the total cost of ownership, not just the initial price.

Summary: Powering Precision and Efficiency in Industrial Processes

Cartridge heating elements are highly versatile, durable, and precise tools for industrial heating. They deliver concentrated heat exactly where it's needed, making them essential for everything from plastic molding to medical devices and 3D printers.

Their benefits include precise and even heating, quick warm-up times, compact size, durability, and energy efficiency. They are also highly customizable and easy to maintain, leading to lower overall costs.

To choose the right heater, understand your application's needs, match the heater's specs to your goals, and select a reliable supplier who can be a true partner. Proper installation, regular maintenance, and knowing how to troubleshoot common issues are also key to maximizing their performance and lifespan. By following these guidelines, industries can use cartridge heaters to achieve excellent precision and efficiency in their heating tasks.

Latest Posts

If you have any needs, please contact us

If You Have Any Needs, Please Contact Us