Finding the right cartridge heater can be tricky, but getting it wrong wastes money and time. Are you considering all the factors beyond just wattage?

When purchasing cartridge heaters, always look beyond just the "power" rating. Instead, you need to consider heating requirements, installation environment, and expected service life together. Misjudging any of these can lead to premature failure and operational inefficiencies.

I've learned that overlooking critical factors in the purchasing process often leads to expensive downtime. Let's dig deeper into what truly matters to make sure you get the perfect fit for your needs.

Are You Calculating Power Density Correctly?

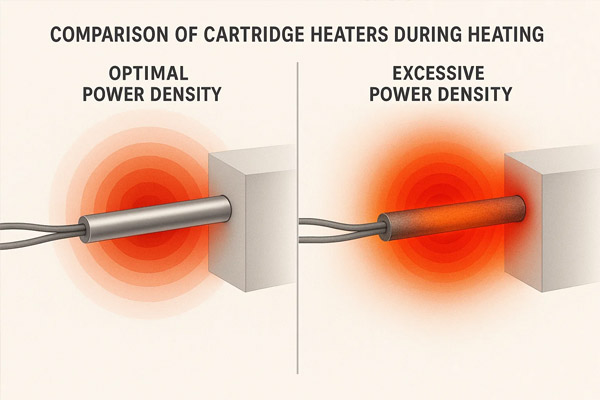

Ignoring power density can drastically shorten your heater's life, causing early failures and costly replacements. Do you know how much heat your heater surface can truly handle?

The first critical step is to calculate power density, which is the watts per square centimeter of the heating surface. This metric dictates how much heat stress the heater material endures. It directly impacts the operational lifespan and safety of your cartridge heater.

We often see issues when customers focus only on total wattage for their heating applications. For example, in mold heating, if the power density is too high, the heater's surface temperature can skyrocket. This quickly turns the magnesium oxide insulation into powder. The heater's lifespan, which should be years, reduces to mere months. My advice is to target ≤12 W/cm² for mold heating applications. If you're using it in dry burning scenarios, it's best to stay below ≤8 W/cm². Exceeding these limits causes the tube surface temperature to soar, leading to rapid pulverization of the magnesium oxide insulation and a drastically shortened lifespan. At ELEKHEAT, we use our advanced equipment to precisely control these densities for our customers.

Why Power Density Matters for Longevity

When a cartridge heater operates, the heat it generates must transfer away efficiently. If the power density is too high, the heat builds up faster than it can dissipate.

- Heat Stress: High power density means more heat concentrated in a smaller area. This puts immense thermal stress on the heater components, especially the resistance wire and the magnesium oxide (MgO) insulation.

- MgO Degradation: MgO powder is an excellent electrical insulator and heat conductor when intact. However, sustained high temperatures cause it to chemically degrade and turn into powder. This powdered state reduces its thermal conductivity, leading to even higher internal temperatures. It also compromises its insulating properties, which can cause short circuits.

- Sheath Corrosion: High surface temperatures also accelerate oxidation and corrosion of the heater sheath material, especially in demanding environments. This can lead to cracks or holes, exposing internal components and causing complete failure.

- Application Impact:

- Molds: Overheating can damage sensitive mold materials or cause uneven heating, affecting product quality.

- Dry Burning: Without a medium to transfer heat, dry burning is especially susceptible to high surface temperatures. This makes adhering to a lower power density crucial.

Are Your Measurements Precise Enough for Optimal Fit?

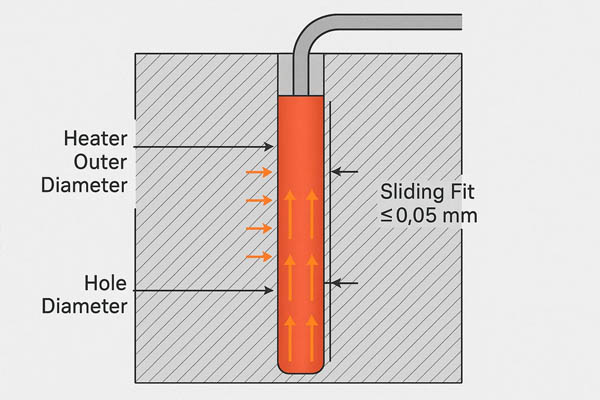

An imprecise fit between your cartridge heater and its bore dramatically reduces heating efficiency and can cause localized overheating. Are you measuring correctly for maximum heat transfer?

Accurate measurements for the bore diameter and depth are fundamental for efficient heat transfer and preventing "cold spots." A precise fit ensures the heater's surface is in close contact with the heated material, allowing heat to conduct effectively without unnecessary energy loss.

We often encounter situations where variations in bore diameters lead to inconsistent heating on a production line. This inconsistency directly impacts product quality. To ensure maximum heat transfer, the hole diameter in your application needs to be precisely measured against the heater's outer diameter. We aim for a "slip fit" with a single-sided gap of less than 0.05 mm. This tight tolerance ensures optimal contact for efficient heat conduction. Furthermore, the installation depth should extend 20-30 mm deeper than the heater's actual heating zone. This extra depth prevents the "cold end" of the heater from wasting energy and ensures the entire heated area is utilized effectively.

Achieving the Perfect Fit: Diameter and Depth

The interface between the heater and the material it heats is where all the magic happens.

- Diameter Tolerance (Slip Fit):

- Importance: A gap between the heater and the bore acts as an air pocket. Air is a poor heat conductor, so even a small gap significantly hinders heat transfer. This leads to the heater running hotter internally than intended and the heated object taking longer to reach temperature.

- Ideal Fit: A "slip fit" (0.05 mm single-sided clearance) allows the heater to be inserted and removed easily while providing excellent thermal contact. This maximizes the efficiency of heat transfer by conduction.

- Consequences of Poor Fit: If the gap is too large, it can cause the heater to overheat internally and fail prematurely due to localized hot spots. If it's too tight, installation becomes difficult, potentially damaging both the heater and the bore.

- Installation Depth:

- Importance: Ensuring the heater is deep enough prevents heat loss from the unheated "cold end" of the bore. It also makes sure the entire effective heating length of the cartridge heater is engaged with the material.

- Optimal Depth: Positioning the heater's heating zone deeper than the bore by 20-30 mm ensures that the entire heated section is utilized. This improves overall thermal efficiency and prevents unnecessary energy consumption at the "cold end."

Are You Choosing the Right Internal Structure?

The internal structure, specifically the lead wire type, impacts the heater's resilience and ease of maintenance. Are you matching the lead type to your operational environment?

The choice between internal and external lead wire structures is not trivial. It dictates how easily the heater can be installed or replaced, and how well it withstands mechanical stress or tight spaces. Each type is suited for distinct application requirements.

We've observed that damaged wiring is a common issue when the wrong lead type is selected. For applications requiring frequent disassembly or where space is very tight, internal lead wires are often the better choice. They offer better protection against bending and damage. On the other hand, external lead wires are much easier to replace on-site if they get damaged, but you must make sure to protect them with a fiberglass protective sleeve to prevent kinking or breakage during operation.

Lead Wire Structures: Internal vs. External

The design of the lead wire connection significantly impacts the heater's performance and maintenance.

- Internal Lead Wires:

- Advantages: These wires are encased within the heater's sheath for a short distance before exiting, offering superior protection against mechanical stress, bending, and abrasive environments. This design is robust and ideal for applications where the heater might be subjected to vibration or frequent handling. They are also excellent for tight spaces where external connections might interfere.

- Disadvantages: If the lead wire itself is damaged, the entire heater often needs replacement, as field repair of the internal connection is difficult or impossible.

- Best For: High-vibration applications, frequent removal and reinstallation, tight mounting spaces, and environments where external wires are prone to damage.

- External Lead Wires:

- Advantages: The lead wires are directly connected to the heating element at the end of the heater, making them easier to access and replace if damaged. This simplifies field maintenance and can reduce downtime if a wire issue occurs.

- Disadvantages: They are more susceptible to mechanical damage, bending, and abrasion without proper protection. A fiberglass protective sleeve is essential to guard against kinking or wear at the exit point, especially in dynamic applications.

- Best For: Applications where lead wire replacement needs to be quick and easy, less constrained spaces, and situations where the external environment is not overly harsh on the wiring.

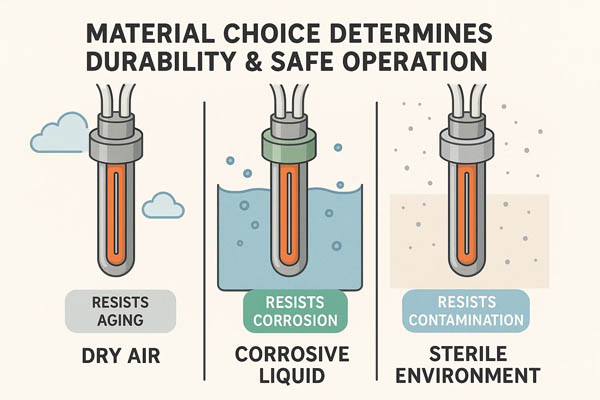

Are You Matching the Material to the Usage Scenario?

Using the wrong heater material for your application's environment leads to rapid corrosion, failure, and safety hazards. Are you selecting based on the actual conditions?

Material selection is paramount for a cartridge heater's durability and safe operation. Different environments, whether dry air, corrosive liquids, or sterile conditions, demand specific sheath materials to resist degradation and maintain performance. This choice directly influences lifespan and prevents material failure.

At ELEKHEAT, we've helped countless customers navigate the complex world of material science for their heaters. For example, some food processing plants initially using standard stainless steel for baking ovens faced rapid corrosion and contamination issues. This happened because the material couldn't withstand specific high temperatures and chemical exposure. We then recommend switching to 840 alloy, which is FDA-compliant and far more resilient. For air dry burning, prioritize 304 stainless steel with a lower power density, and always pair it with a forced air fan for heat dissipation. For liquid heating, you must first check the corrosion spectrum of the liquid. For tap water or weak acids, 316L stainless steel is usually suitable. However, for strong acid plating baths, you should directly opt for titanium tubes or Teflon protective sleeves. Crucially, always ensure the "cold end" of the heater is above the liquid level to prevent dry burning. For food baking or medical sterilization applications, 840 alloy or Incoloy 800 is required to meet FDA-grade cleanliness standards.

Material Selection Table

| Usage Scenario | Recommended Material | Key Considerations & Why |

|---|---|---|

| Air Dry Burning | 304 Stainless Steel | Requires low power density (≤8 W/cm²) and mandatory forced air fan for dissipation to prevent overheating and degradation. |

| Tap Water / Weak Acids | 316L Stainless Steel | Offers enhanced corrosion resistance compared to 304 SS, suitable for mildly corrosive aqueous solutions. |

| Strong Acids / Plating | Titanium Tube / Teflon Sheath | Titanium provides extreme corrosion resistance to many strong acids. Teflon sheaths offer chemical inertness. |

| Food / Medical (Sterile) | 840 Alloy / Incoloy 800 | These alloys offer high temperature resistance and meet FDA cleanliness standards, ensuring no contamination. |

| Molten Metal / Salt | Inconel 600 / Incoloy 800 | Excellent high-temperature strength and corrosion resistance against aggressive molten substances. |

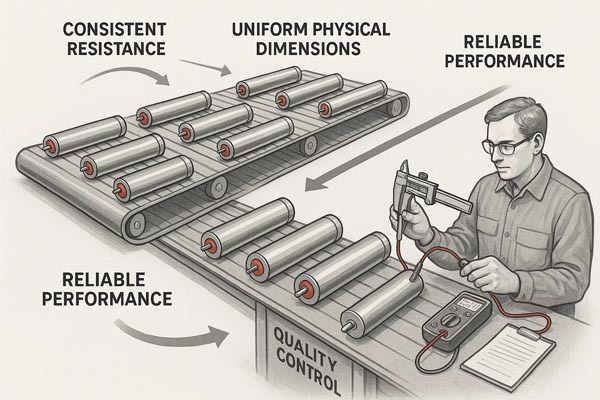

Are You Overlooking Production Line Consistency?

For bulk orders, inconsistent heater performance can derail an entire production line, leading to costly waste and delays. Are you demanding consistency and proper quality control from your supplier?

Production line consistency is a critical, yet often overlooked, aspect of B2B cartridge heater procurement. For bulk orders, ensuring uniform performance, resistance values, and physical dimensions across batches prevents operational disruptions and guarantees the reliability of automated systems.

In our experience, consistency is key for industrial clients. We often see that variations in heater performance from different batches can cause significant downtime and rework if not managed. The fifth step, which B-side buyers often ignore, is "production line consistency." For bulk orders, you absolutely must demand that your supplier provides factory reports detailing resistance values within ±3% and length tolerances within ±0.1 mm for the same batch. Also, ensure a quality assurance agreement is signed. For production lines operating 24 hours continuously, we even perform additional 1000-hour high-temperature aging random inspections to ensure an early failure rate target of 1%. This rigorous testing ensures that every ELEKHEAT heater performs reliably.

Ensuring Batch Uniformity and Quality Control

When your production depends on hundreds or thousands of heaters, minor variations can snowball into major problems.

- Resistance Value Consistency (±3%):

- Why it matters: Resistance directly determines the power output of a heater (P = V²/R). If resistance varies significantly between heaters in a batch, their power outputs will also vary. This leads to uneven heating, inconsistent product quality, and potentially overloading some circuits while underutilizing others.

- Supplier Requirement: Demand a factory report for each batch confirming that resistance values fall within a tight tolerance (e.g., ±3%) of the specified value.

- Length Tolerance (±0.1 mm):

- Why it matters: In automated assembly lines or applications requiring precise positioning, even small variations in heater length can cause fitment issues. This can lead to improper heat transfer, damage during installation, or failure to integrate with machinery.

- Supplier Requirement: Ensure the supplier provides documentation guaranteeing length consistency within ±0.1 mm, especially for critical applications.

- Warranty and QA Agreements:

- Importance: A robust warranty and clear Quality Assurance (QA) agreement protect you against defects and premature failures. It outlines the responsibilities of both parties.

- What to include: Specify performance guarantees, acceptable failure rates, replacement procedures, and any conditions for claims.

- 1000-Hour High-Temperature Aging Test (for 24/7 lines):

- Why it matters: For continuous operation, early failures are extremely costly. This test simulates prolonged high-stress conditions to identify heaters prone to infant mortality.

- Target: Aim for an early failure rate of 1% or less, confirming the batch's long-term reliability.

Are You Matching Voltage to Resistance Correctly?

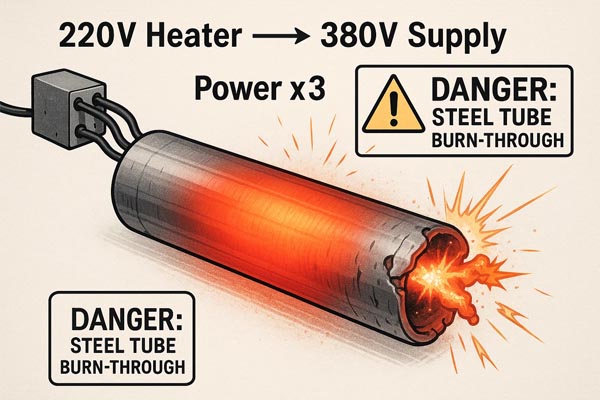

Plugging a heater into the wrong voltage can instantly triple its power output, leading to immediate burnout and potential hazards. Are you verifying this critical match?

The final, yet often most overlooked, step is ensuring a perfect match between the applied voltage and the heater's inherent resistance. A mismatch can dramatically alter the power output, leading to severe overheating, rapid heater failure, and potential safety risks due to uncontrolled heat generation.

Voltage mismatch can lead to catastrophic results. For instance, plugging a 220V rated heater into a 380V power supply causes the power output to instantly triple. The heater's surface load explodes, and within minutes, the steel tube can burn through, creating a dangerous situation. This is why you must never forget "voltage-resistance" matching. The resistance of a finished heater tube is fixed during manufacturing. If you carelessly plug a 220V rated tube into a 380V supply, the power output will instantly multiply by three. This surge in surface load will cause the heater to burn through its steel casing in mere minutes. Always verify this critical match before operation.

The Physics of Voltage-Resistance Mismatch

Understanding Ohm's Law is key to preventing catastrophic failures.

- Ohm's Law (P = V²/R):

- P = Power (Watts): The rate at which energy is converted to heat.

- V = Voltage (Volts): The electrical potential difference.

- R = Resistance (Ohms): The opposition to current flow.

- Impact of Voltage: Notice that voltage (V) is squared in the formula. This means even a small increase in voltage leads to a disproportionately large increase in power.

- Example (220V vs. 380V):

- Imagine a heater designed for 220V with a specific resistance (R).

- Power at 220V = (220)² / R

- If you connect this same heater (with the same R) to 380V:

- Power at 380V = (380)² / R

- Calculate the ratio: (380)² / (220)² ≈ 2.99. This is why the power output nearly triples!

- Consequences of Overpowering:

- Rapid Overheating: The heater generates far more heat than it's designed to dissipate.

- Material Breakdown: The internal resistance wire melts, the MgO insulation degrades, and the sheath material can burn through.

- Fire Hazard: Extreme heat can ignite nearby materials, posing a severe safety risk.

- System Damage: The sudden surge in power can damage control systems or other components in the circuit.

Conclusion

To buy cartridge heaters precisely and ensure longevity, first calculate power density, then measure dimensions accurately. Next, select the right structure, choose material based on the scenario, and confirm voltage matching. Finally, include batch consistency in your contract.