Are you struggling with inconsistent heater performance and early failures? Do poor heat transfer and unreliable operation slow your production? A cartridge heater sleeve is the critical link to unlock the full potential of your heating elements.

A cartridge heater sleeve is a mechanical-thermal interface designed for cartridge heaters. It works as a locating guide, a heat dissipation node, and a sealing gate. A good sleeve solves thermal expansion alignment, electrical insulation, vibration loosening, and media leakage issues. This ensures long-term, high-performance heating.

Understanding how this small but important part works can change your heating processes. Let us look at how a good sleeve makes systems more reliable and efficient.

What are the core functions of a cartridge heater sleeve?

Are you tired of uneven heating and unexpected downtime? Does your system lack stable and precise heat delivery? Knowing the main jobs of a cartridge heater sleeve shows its key role in steady heating.

The core functions of a cartridge heater sleeve include exact geometric anchoring, strong force-thermal coupling, good sealing and isolation, and easier maintenance. These roles turn a simple heater into a high-performance, long-lasting thermal part for tough uses.

A cartridge heater sleeve is a core component. It solves four main problems: thermal expansion, electrical insulation, vibration, and leakage. Our commitment is to solve these issues from the start, turning a simple heater into a reliable thermal module.

Core Functions of a Cartridge Heater Sleeve

| Function | Description | Benefit |

|---|---|---|

| Geometric Anchoring | Uses H7/g6 tolerances to keep the heater gap under 0.05 mm. This stops "tube rubbing" and keeps heat transfer steady. | Maintains exact heater position, stops wear, and ensures even heating. |

| Force-Thermal Coupling | 8.8 grade screws apply 12–15 N·m preload. This cuts contact thermal resistance to below 0.05 K·W⁻¹. Plate elastic rebound makes up for 0.08 mm thermal expansion, stopping "thermal loosening." | Gets efficient heat transfer and keeps connections tight, even at 650 ℃. This stops hot spots and makes heaters last longer. |

| Sealing and Isolation | Integrates PTFE or Viton seals for 10 bar pressure. It keeps 240 V electrical parts separate from the 316L casing. It meets IEC 60335 (2.5 kV). | Ensures process safety in food-grade or high-pressure uses. It gives vital electrical safety for rules and user protection. |

| Maintainability | Modular 8 mm plate needs only 4 screws for removal. This cuts heater replacement time from hours to minutes. | Increases uptime for 24×7 lines. This can add 0.3 % yearly production capacity. It saves time and operating costs. |

What types of cartridge heater sleeves exist and how do I choose one?

Does the wide range of heater sleeves confuse you? Are you unsure how to pick the best sleeve for your unique setup? Different types of sleeves offer specific benefits for various industrial applications.

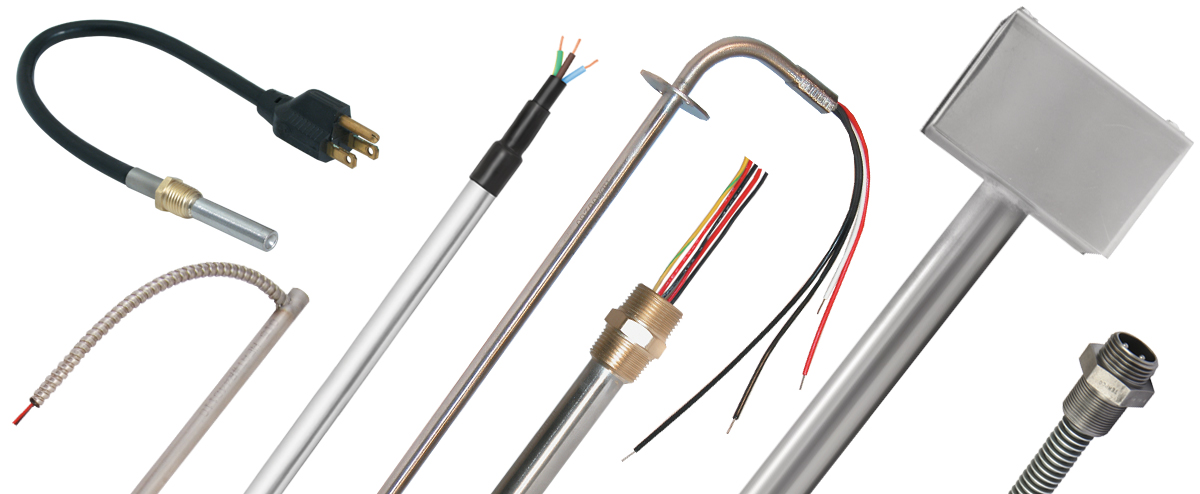

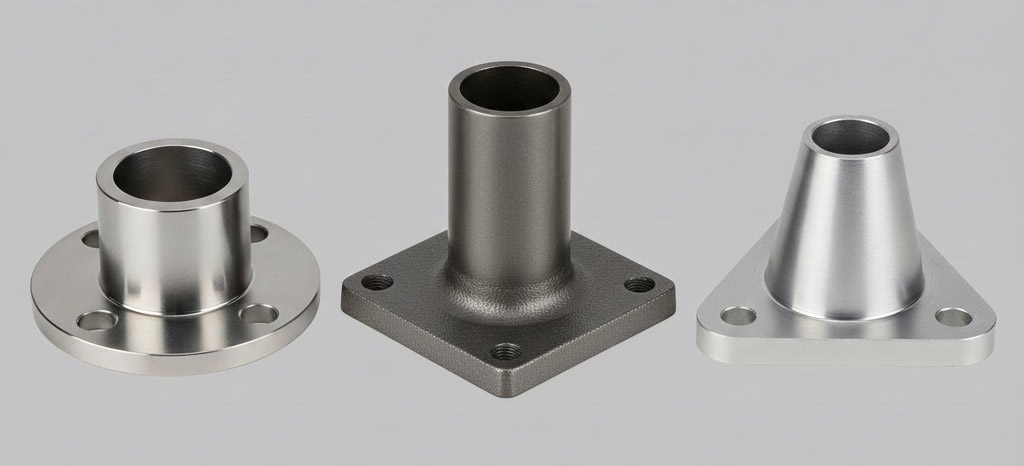

Cartridge heater sleeves come in many forms. We group them by shape, heat path, electrical rating, and material. Choosing the right one depends on your exact needs. Consider temperature, pressure, electrical insulation, and environment. Each type helps performance and lifespan for different industrial jobs.

Selecting the right cartridge heater sleeve is very important for system performance and how long it lasts. We look at its design, material, heat transfer, electrical safety, and how it handles tough environments. Our goal is to find the perfect sleeve for your needs. This ensures good function, best efficiency, and a long life.

Cartridge Heater Sleeve Types and Selection

| Type Category | Specific Types & Features | Key Application & Benefit |

|---|---|---|

| Outer Shape | Round Flange (DN32–DN100): Connects with DIN 2633 flanges. <br>Square Plate (30×30–120×120 mm): For side-by-side tube layout (3–6 tubes, 12 mm spacing). <br>Triangular Bracket: Light (<15g), for aerospace (14g vibration). | Round: Melt-blown die heads, hot runner systems. <br>Square: Packaging machine heat seal bars for even heating. <br>Triangular: Aerospace de-icing pads, balancing weight and vibration. |

| Heat Transfer Path | Pure Conduction: 5–12 mm thick, 6061-T6 aluminum (λ≈167 W·m⁻¹·K⁻¹). <br>Liquid-Cooled: Inside 6 mm spiral groove for 50 % ethylene glycol. | Conduction: For temperatures below 300 ℃. <br>Liquid-Cooled: PET preform injection to lower head temp (250 ℃ to 120 ℃), stops acetaldehyde. |

| Electrical Rating | Low Voltage (≤48 V): Integrated plate/casing. <br>High Voltage Isolation (600 V): Embedded 0.5 mm ceramic ring, creepage ≥8 mm (UL 1030). | Low Voltage: New energy car battery heating, saves space. <br>High Voltage: High-voltage industrial uses, ensures electrical safety. |

| Material | Aluminum Alloy: Light, easy to work with, Ni plating for >400 ℃. <br>Stainless Steel 321: Resists 800 ℃ oxidation, matches Incoloy 840 (16.5×10⁻⁶ K⁻¹ CTE). <br>Titanium Alloy: Resists 5 % citric acid corrosion. | Aluminum: Medium temps, good for general use. <br>Stainless Steel: High-temp, lowers heat stress, long life. <br>Titanium: Medical sterilizers, 10x life improvement over 304, high corrosion resistance. |

What engineering insights ensure optimal cartridge heater sleeve performance?

Are your heating systems still facing unexpected breakdowns or energy waste? Does your current setup struggle to deliver consistent, long-term performance? Our engineering experience offers crucial tips for achieving peak performance and reliability.

Optimal cartridge heater sleeve performance relies on important engineering insights. These include careful choices for fit, smart screw placement for steady clamping force, and thermal imaging checks. This confirms good heat transfer. Paying attention to these details makes parts last longer and stops dangerous hot spots.

At ELEKHEAT, we have learned that small details in design and setup matter greatly. A cartridge heater sleeve changes a simple rod into a reliable, locatable, and maintainable thermal part. We always look at thermal resistance first, then thermal expansion, and third, sealing. If these three points are met, the life can go from 2,000 to 20,000 hours.

Key Engineering Practices for Cartridge Heater Sleeves

| Practice | Details & ELEKHEAT Recommendation | Outcome |

|---|---|---|

| Fit (Over-sizing/Clearance) | Tube ≤ 12 mm: 0.02 mm clearance + thermal grease. <br>Tube ≥ 15 mm: 0.05 mm interference + liquid nitrogen cold assembly (cuts thermal resistance by 0.01 K·W⁻¹). | Makes heat transfer best and ensures strong thermal contact for different heater sizes. |

| Screw Placement | 4 screws (90°): Preload force drops 18 % after 1000 cycles. <br>6 screws (60°): Preload force drops only 7 %. No need for anti-loosening washers. | Keeps clamping force steady, stopping loosening and ensuring stable thermal contact over time. |

| Thermal Imaging Verification | At 1.5 W·mm⁻² power, fixed plate/tube shell temperature difference should be <5 ℃. <br>If >15 ℃ hot spots appear, contact area is <70 %; rework is needed. | Confirms best heat transfer and contact. Finds big problems like bad assembly, ensuring safety and efficiency. |

Conclusion

A cartridge heater sleeve is essential for reliable thermal systems. Proper selection and careful application, guided by our engineering insights, ensure extended heater life and predictable performance. We know this leads to better efficiency for our customers.